2

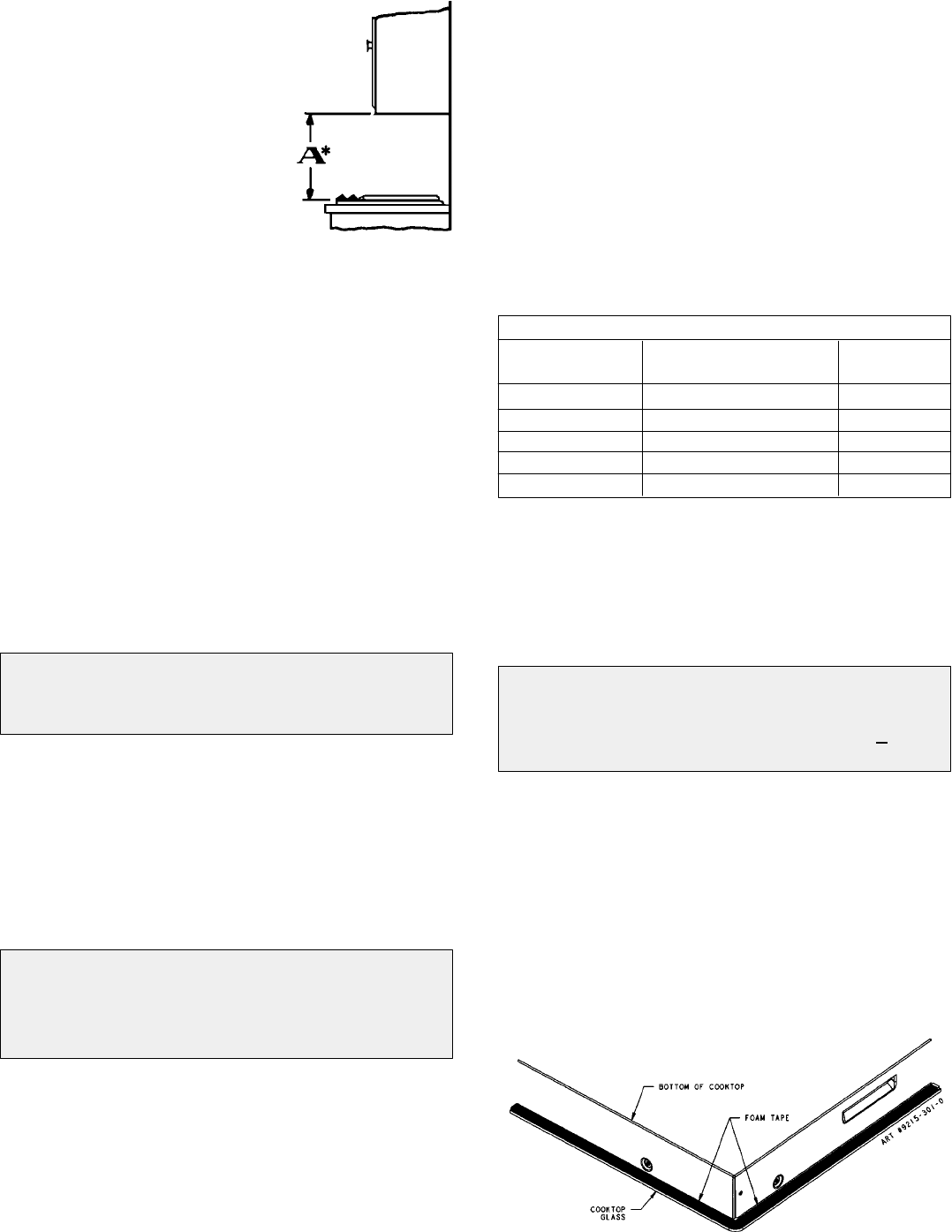

Installing Cabinetry Over Your Cooktop

A= 30²

²²

² (76.2 cm) minimum

clearance between the top of

the cooktop and the bottom of

an unprotected wood or metal

cabinet.

A= 24²

²²

² (60.96 cm) minimum when

bottom o f wood or metal

cabinet is protected by not less

than 1/4² (0.635 cm). FLAME

RETARDANT millboard

covered with not less than no.

28 MSG sheet steel, 0.015²

(0.038 cm) stainless steel, 0.024²

(0.061 cm) aluminum or copper.

* To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches beyond the bottom of the cabinets.

Important Installation Suggestions

1. Chamfer all exposed edges of decorative laminate to

prevent damage from chipping.

2. Radius corners of cutout and file to insure smooth

edges and prevent corner cracking.

3. Rough edges, inside corners which have not been

rounded and forced fits can contribute to cracking of

the countertop laminate.

4. Countertop must be supported within 3² (7.62 cm) of

cutout.

CAUTION

Warranty is void on equipment installed other than

as recommended by manufacturer.

Electrical Wiring Information

If used on new branch-circuit installations (1996 NEC),

mobile homes, recreational vehicles, or in an a rea where

local codes prohibit grounding through the neutral

conductor, connect the ground wire to ground in

accordance with local code. Connect all wires to the

branch circuit with approved connectors. Use copper or

aluminum wire. If aluminum wire is used, use connectors

recognized for joining aluminum to copper.

CAUTION

This is a two wire with copper ground 208/240 volt

AC appliance. Copper ground is chassis ground

and must be connected to supply ground.

Proper Electrical Supply

You must provide an adequate electrical supply system

as required for your cooktop. All wire connections must be

in accordance with local codes and properly insulated.

Check with local utility for governing electrical codes and

ordinances. In the absence of local electrical codes, the

National Electrical Code, NFPA No. 70, governing electric

range installations must be followed. A copy of the

National Electrical Code, NFPA No. 70, can be obtained

by writing to:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

This is a 2-wire, 240-volt unit. Connect only to a 3-wire,

120/240-volt power supply; the neutral conductor is not

required for the operation of the appliance. The potential

at the power supply electrical connections shall be

150-volts-to-ground or less. The grounding (bare) wire is

connected to the frame of the unit; connect it to a

separate ground. The chart below recommends the

minimum circuit protector and wire size if the appliance is

the only unit on the circuit. If smaller sizes of wire are

used, the unit efficiency will be reduced and a fire hazard

may b e created. It is advisable that the electrical wiring

and hookup be accomplished by a competent electrician.

RECOMMENDED MINIMUM

K.W. RATING CIRCUIT PROTECTION WIRE SIZE

ON SERIAL PLATE IN AMPRES (AWG)

0- 4.8 20 12

4.9 - 6.9 30 10

7.0 - 9.9 40 8

10.0 - 11.9 5 0 8

12.0 - 14.9 6 0 6

Notice To Installer

Follow a ccompanying i nstruction carefully.

Preparation Of Countertop

The cutout in the countertop into which the appliance is to

be installed should be prepared according to the cutout

dimensions given on page 1 of these instructions.

CAUTION

Cutout dimensions are critical. Dimensions must

be measured and cut accurately to within +

1/16²

(.16 cm) to insure proper fit.

Installation Of Appliance

1. Remove the cooktop from the carton.

2. Provide cutout in countertop a s required per page 1.

3. Place unit in the cutout.

4. Optional - Foam Tape Installation - see illustration

figure 3. Apply foam tape to cook top a s shown in

figure 3 if counter top is not flat.

5. Make electrical wire connection to unit. Consult local

codes for proper power hook-up.

6. Test to insure touch controls operate all elements

properly.

FIGURE 3