2. IFTHISISA30" WIDECOOKTOPANDAJENN-NR,MODEL

W30XXXORW131,ELECTRICWALLOVENISTOBEINSTALLED

BELOWTHISCOOKTOR

NOTE1:Thisapplianceanditsgasandelectricalsupplysourcesmustbe

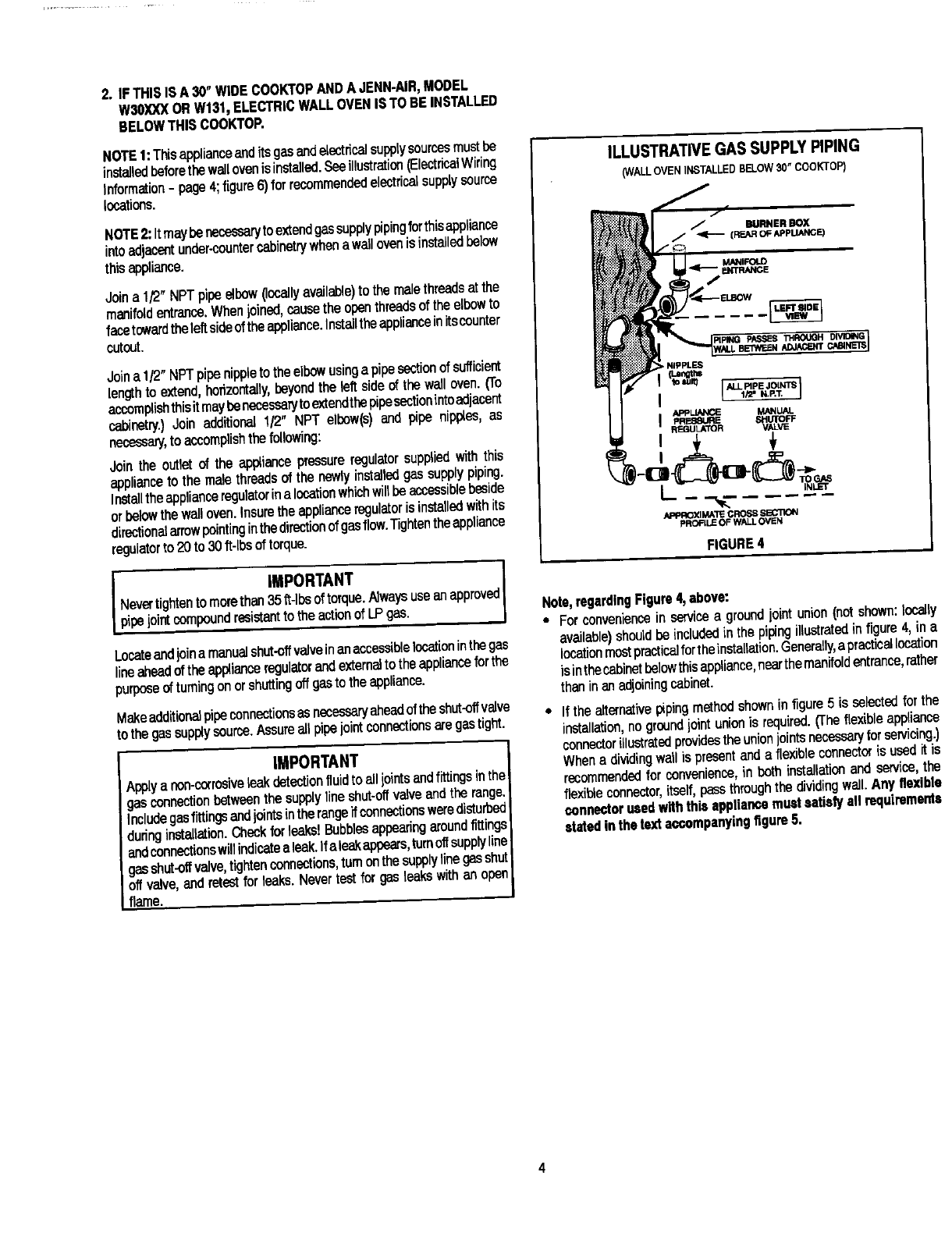

installedbeforethewallovenisinstalled,Seeillustration(ElectricalWiring ILLUSTRATNEGASSUPPLYPIPING

tnformahon- page4;figure6)forrecommendedelectricalsupplysource (WALLOVENINSTALLEDBELOW30"COOKTOP)

(ovations.

NOTE2:Itmaybenecessarytoextendgassupplypipingforthisappliance 7 =_'_EReox

intoadjacentunder-countercabinetrywhenawallovenisinstalledbelow j _ (Rz,_oF_a

thisappliance.

Joina 1/2"NPTpipeelbow(locallyavailable)tothemalethreadsatthe I

manifoldentrance.Whenjoined,causetheopenthreadsoftheelbowto

facetowardtheleftsideoftheappliance.Installtheapplianceinkscounter

cutout.

Joina 1/2"NPTpipenippletotheelbowusingapipesectionofsufficient

lengthtoextend,horizontally,beyondtheleftsideofthewalloven.(To I _"¢"

t_="_ [ lr,.N.p.,. ]

accomplishthisitmaybenecessarytoextendthepipesectionintoadjacent I ALL_PEao_xrs

cabinetry.)Joinadditional1/2" NPT elbow(s)and pipenipples,as

necessary,toaccomplishthefollowing:

Jointhe outletof the appliancepressureregulatorsuppliedwiththis

appliancetothemalethreadsofthenewlyinstalledgassupplypiping. __.

InstaUtheapplianceregulatorina locationwhichwillbeaccessiblebeside _N_

orbelowthewalloven.Insuretheapplianceregulatorisinstalledwithits L- _ .,%._

directionalarrowpointinginthedirectionofgasflow.Tightentheappliance ,_FgCO_MA_CROSSSZC'nU_

pROFILE OF WALL OVEN

regulatorto20to30ft-lbsoftorque. FIGURE4

IMPORTANT ]

NevertJghtantomorethan35ft-lbsoftorque.AlwaysuseanapprovedI

pipejointcompoundresistanttotheactionofLPgas. ] Note,regardingFigure4,above:

• Forconvenienceinservicea groundjointunion(notshown:locally

Locateandjoinamanualshut-offvalveinanaccessiblelocationinthegas available)shouldbeincludedinthepipingillustratedinfigure4, in

lineaheadoftheapplianceregulatorandexternaltotheapplianceforthe locationmostpracticedfortheinstallation.Generally,apracticaliccatlor

purposeofturningonorshuttingoffgasto theappliance, isinthe_binetbelowthisappliance,nearthemanifoldentrance,rathe

thaninanadjoiningcabinet.

Makeadditionalpipeconnectionsasnecessaryaheadoftheshut-offvalve • Ifthealternativepipingmethodshowninfigure5 is selectedforthe

tothegassupplysource.Assureallpipejointconnectionsaregastight, installation,nogroundjointunionisrequired.(Theflexibleapplianc_

connectorillustratedprovidestheunionjointsnecessaryforservicing.I

IMPORTANT Whenadividingwallispresentanda flexibleconnectoris usediti=

Applyanon-corrosiveleakdetectionfluidtoalljointsandfittingsinthe recommendedforconvenJanse,in bethinstallationand service,th_

gasconnectionbetweenthesupplylineshut-offvalveandtherange, flexibleconnector,itself,passthroughthedividingwall.Anyflexlbl

includegasfittingsandjointsintherangeifconnectionsweredisturbed connectorusedwiththisappliancemustsatisfyall requirement

duringinstallation.Checkforleaks!Bubblesappearingaroundfittings statedinthetextaccompanyingfigureS.

andconnectionswillindicatealeak.Ifaleakappears,turnoffsupplyline

'gasshut-offvalve,tightenconnections,turnonthesupplylinegasshut

Ioffvalve,andretestforleaks.Nevertestforgasleakswithanopen

iflame.