SECTION 1. COMPONENT DESCRIPTION

COMPONENTS

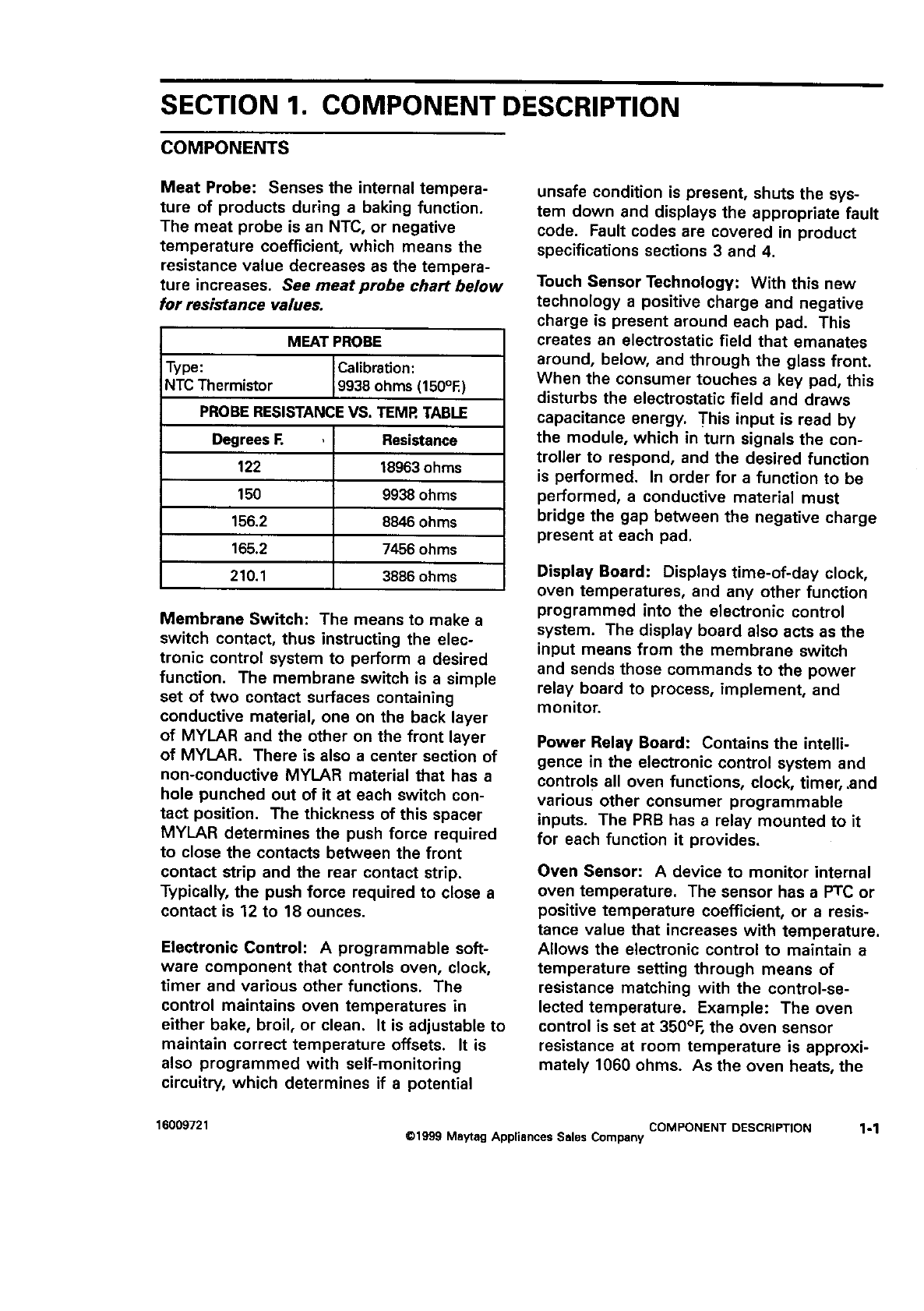

Meat Probe: Senses the internal tempera-

ture of products during a baking function.

The meat probe is an NTC, or negative

temperature coefficient, which means the

resistance value decreases as the tempera-

ture increases. See meat probe chart below

for resistance values.

MEAT PROBE

Type: Calibration:

NTC Thermistor 9938 ohms (150°F.)

PROBE RESISTANCE VS. TEMR TABLE

Degrees E Resistance

122 18963 ohms

150 9938 ohms

156.2 8846 ohms

165.2 7456 ohms

210.1 3886 ohms

Membrane Switch: The means to make a

switch contact, thus instructing the elec-

tronic control system to perform a desired

function. The membrane switch is a simple

set of two contact surfaces containing

conductive material, one on the back layer

of MYLAR and the other on the front layer

of MYLAR. There is also a center section of

non-conductive MYLAR material that has a

hole punched out of it at each switch con-

tact position. The thickness of this spacer

MYLAR determines the push force required

to close the contacts between the front

contact strip and the rear contact strip.

Typically, the push force required to close a

contact is 12 to 18 ounces.

Electronic Control: A programmable soft-

ware component that controls oven, clock,

timer and various other functions. The

control maintains oven temperatures in

either bake, broil, or clean. It is adjustable to

maintain correct temperature offsets. It is

also programmed with self-monitoring

circuitry, which determines if a potential

unsafe condition is present, shuts the sys-

tem down and displays the appropriate fault

code. Fault codes are covered in product

specifications sections 3 and 4.

Touch Sensor Technology: With this new

technology a positive charge and negative

charge is present around each pad. This

creates an electrostatic field that emanates

around, below, and through the glass front.

When the consumer touches a key pad, this

disturbs the electrostatic field and draws

capacitance energy. This input is read by

the module, which in turn signals the con-

troller to respond, and the desired function

is performed. In order for a function to be

performed, a conductive material must

bridge the gap between the negative charge

present at each pad.

Display Board: Displays time-of-day clock,

oven temperatures, and any other function

programmed into the electronic control

system. The display board also acts as the

input means from the membrane switch

and sends those commands to the power

relay board to process, implement, and

monitor.

Power Relay Board: Contains the intelli-

gence in the electronic control system and

controls all oven functions, clock, timer, ,and

various other consumer programmable

inputs. The PRB has a relay mounted to it

for each function it provides.

Oven Sensor: A device to monitor internal

oven temperature. The sensor has a PTC or

positive temperature coefficient, or a resis-

tance value that increases with temperature.

Allows the electronic control to maintain a

temperature setting through means of

resistance matching with the control-se-

lected temperature. Example: The oven

control is set at 350°F, the oven sensor

resistance at room temperature is approxi-

mately 1060 ohms. As the oven heats, the

16009721 COMPONENT DESCRIPTION 1-1

_1999 Maytag Appliances Sales Company