15

3000STOPR005810R082503

KUHN KNIGHT INC.

1501 West 7th Ave. Brodhead, WI 53520-0167

701 Cherry Ave. Greeley, Co. 80632

INSTALLATION TIPS

1. Be sure there is adequate clearance around the mixer for maintenance, repair and loading the mixer.

2. If the electronic weighing system is used, be sure that the weigh bars are kept clean and dry also

items such as loading conveyors are not attached to or leaning on the mixer. Refer to scale

manual for more specific information.

3. Mixer should be mounted on a structure of adequate strength to support a fully loaded mixer. Machine

must be level and stable at the desired height. Weigh bar mounts should be fastened to this

structure.

4. Manual door opener for the 3015 & 3020 can be mounted at either the front or the rear of the mixer.

The following instructions will help To modify the door opener for operation from the opposite end:

a. Remove latch and mounting bolt and install to opposite end of mixer in corresponding hole.

b. Remove door wheel assembly.

c. With door in fully closed position, cut door wheel shaft to proper length, drill mount hole, slide

into position and replace bolt.

5. The , 3025, 3030, 3036, 3042, 3050, 3060, & 3070 manual door opener is in a fixed position on the

drive end of the mixer.

6. An optional remote electric door actuator is also available for all models. The remote door actuator is

standardon the 3095.

ELECTRIC MOTOR RECOMMENDATIONS

Following is a listing of suggested motor and frame sizes. Ratings are based on “normal dairy feed rations”. Heavier

rations such as feedmill use, heavy/sticky beef rations, or industrial use, contact factory. A smaller motor may be

adequate for easy-mixing materials, and a larger motor may be required for difficult materials*. Wiring and overload

protection should be sized according to the motor size installed. The motor mount will fit the recommended motor

size. Other motor sizes may require additional holes to be drilled in mount or a different mount. Dual motor mount,

frame and shield are standard on 3025, 3030, 3036 & 3042 models. All models are designed to be used with a

motor operating at 1725-1750 RPM.

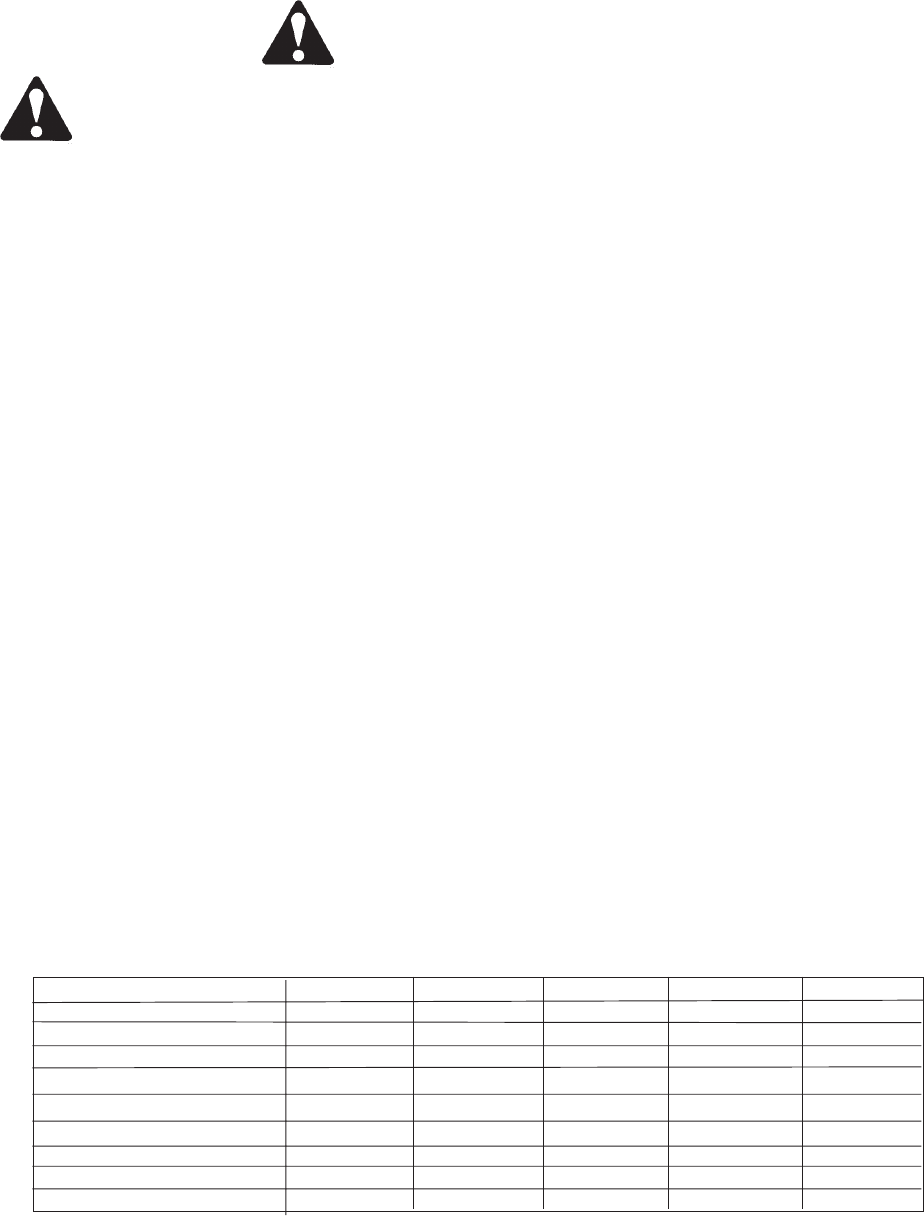

MODEL

*HORSEPOWER

MOTOR FRAME SIZE

STANDARD MOTOR BUSHING

OPTIONAL MOTOR BUSHING

3015

7.5 - 10

213T 215T

1-3/8”

1-1/8”

3020

10

215T 254T

1-3/8”

1-5/8”

3030

10 - 15

254T 256T

1-5/8”

1-3/8”

MODEL

*HORSEPOWER

MOTOR FRAME SIZE

STANDARD MOTOR BUSHING

OPTIONAL MOTOR BUSHING

3025

10

254T 256T

1-5/8”

1-3/8”

3042

15 - 25

284T 286T

1-7/8”

2-1/8”

3036

15 - 20

256T 284T

1-5/8”

1-7/8”

3050

50

326T

2-1/8”

2-1/8”

3060

60

364T

2-3/8”

2-3/8”

3070

75

365T

2-3/8”

2-3/8”

3095

100

N/A

2-7/8”

IMPORTANT! READ BEFORE OPERATING MIXER.

IT IS THE RESPONSIBILITY OF THE OWNER TO MAKE SURE THE MIXER IS SET

UP PROPERLY. THE FOLLOWING RECOMMENDATIONS SHOULD BE HELPFUL

MIXER SETUP