Impinger II – Advantage Digital Express Service Manual - Domestic

2

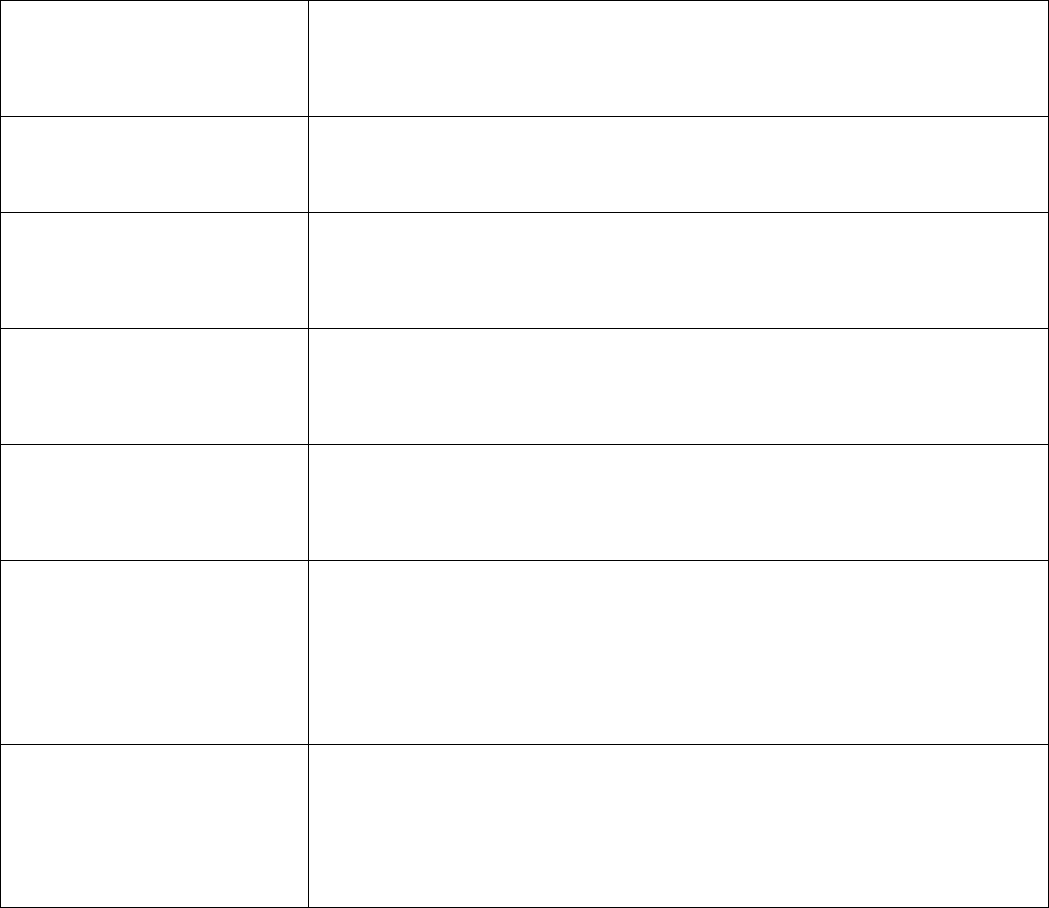

SEQUENCE OF OPERATION

IMPINGER II ADVANTAGE, GAS

(OVENS WITH PUSH BUTTON CONTROLS)

MODEL 1116-080-A NAT. GAS 120VAC 60 HZ. 1 PHASE

MODEL 1116-080-A1 NAT. GAS 120VAC 60 HZ. 1 PHASE

MODEL 1117-080-A LP GAS 120VAC 60 HZ. 1 PHASE

MODEL 1117-080-A1 LP GAS 120VAC 60 HZ. 1 PHASE

POWER SUPPLY Electrical power is supplied to the oven by a three-conductor cordset. Voltage

from the black conductor to the white conductor is 120VAC.

Black conductor is hot

White conductor is neutral.

Green conductor is ground.

CONTROL BOX AUTO

COOL DOWN

When the temperature in the control box reaches 120°F ± 3° (48.9°C ± 1.7°), the

cooling fan thermostat will switch power to the control box cooling fans. The

thermostat will interrupt power to the cooling fans when the control box

temperature falls to 100°F ± 3° (37.8°C ± 1.7°).

MAIN FAN CIRCUIT Power is permanently supplied, through a 10 amp fuse, to the normally open

main power switch. Power is also supplied to the normally open cooling fan

thermostat. Closing the main power switch supplies 120VAC to the main fan

motor, the cooling fan motors, the primary of the control transformer, the

conveyor motor and to the ignition control.

BURNER CIRCUIT Closing the main power switch supplies 120VAC to the burner blower motor.

120VAC is also supplied, through the main fan centrifugal switch (this switch

closes when the main fan reaches approx. 1600 RPM) and the normally closed

oven cavity hi-limit thermostat, to the primary of the burner transformer. 120VAC

is also supplied to the oven control.

IGNITION CONTROL The ignition control operates on both 24VAC and 120VAC. When the control is

energized by 24VAC from the transformer, 120VAC is switched by the ignition

control to the hot surface igniter for 45 seconds for the hot surface igniter warm

up. The igniter glows red, 24VAC is switched to the gas valve, which opens, and

ignition should now occur.

TEMPERATURE CONTROL Closing the main power switch supplies 120VAC to the primary of the oven

control transformer. Secondary voltage, 24VAC, is supplied to the oven control.

The oven control is set to desired temperature. The thermocouple will provide

varying millivolts to the oven control. The oven control supplies 120VAC to the

temperature regulation valve at intermittent intervals to maintain the desired

temperature. The display on the oven control will indicate when the temperature

regulation valve is energized.

NOTE: The display also indicates oven temperature.

CONVEYOR DRIVE Closing the main power switch supplies 120VAC to the conveyor motor and to

the primary of the control transformer. Secondary voltage, 24VAC, is supplied to

the oven control. Setting the oven control to the desired time outputs voltage,

through a reversing switch, to the conveyor motor.

NOTE: The conveyor system uses a hall effect sensor and magnet to prove

operation of the conveyor motor. If the conveyor motor is not running, “BELT

JAM” is indicated on the display.