Before Calling for Service Section 5

5-2

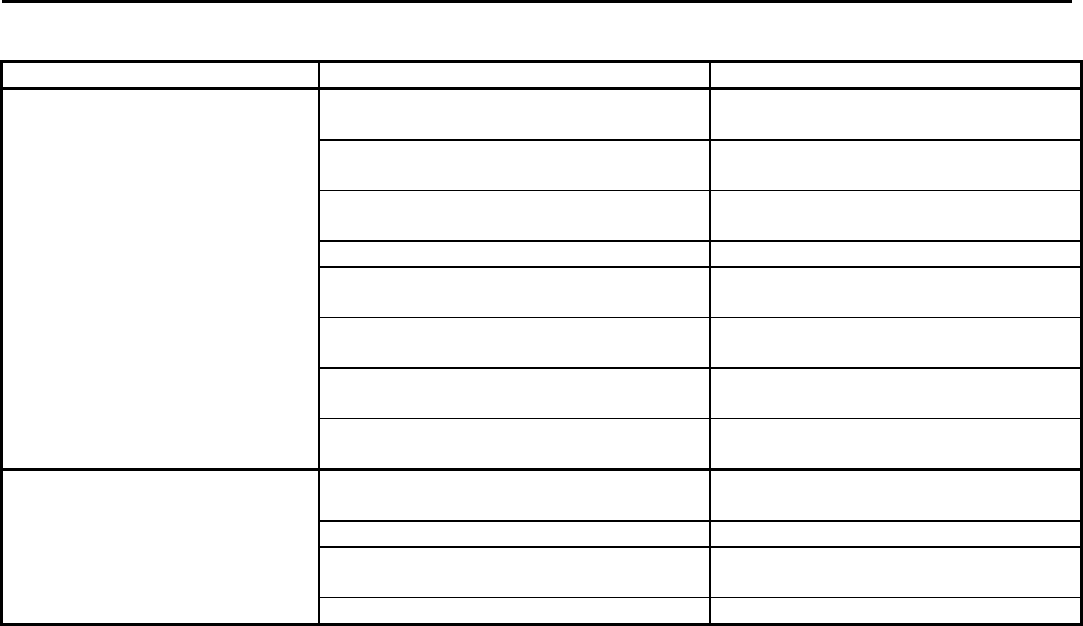

Problem Possible Cause To Correct

Ice machine produces shallow

or incomplete cubes, or the ice

Ice thickness probe is out of

adjustment.

Adjust the ice thickness probe.

fill pattern on the evaporator is

incomplete.

Water trough level is to high or too low.

Set water level.

Water float valve filter screen is dirty. Remove the water float valve and

clean the filter screen.

Water filtration is poor. Replace the filter.

Hot incoming water. Connect the ice machine to a cold

water supply

Water float valve is not working. Remove the water float valve and

clean it.

Incorrect incoming water pressure. Water pressure must be 20-80 psi

(137.9 - 551.5 kPA).

Ice machine is not level. Level the ice machine.

Low ice capacity. Water float valve filter screen is dirty. Remove the water float valve and

clean the filter screen.

Incoming water supply is shut off. Open the water service valve.

Water float valve stuck open or

leaking.

Remove the water float valve and

clean it.

Safety Limit Feature

In addition to the standard safety controls, such as

the high pressure cutout, your Manitowoc ice

machine features built-in safety limits which will

stop the ice machine if conditions arise which could

cause a major component failure.

Before calling for service, re-start the ice machine

using the following procedure:

1. Move the ICE/OFF/CLEAN switch to OFF and

then back to ICE.

A. If the safety limit feature has stopped the ice

machine, it will restart after a short delay.

Proceed to step 2.

B. If the ice machine does not restart, see “Ice

machine does not operate” on the previous

page.

2. Allow the ice machine to run to determine if the

condition is recurring.

A. If the ice machine stops again, the condition

has recurred. Call for service.

B. If the ice machine continues to run, the

condition has corrected itself. Allow the ice

machine to continue running.