Maintenance Section 4

4-8

Part Number 000001528

Ice Machine Inspection

Check all water fittings and lines for leaks. Also, make

sure the refrigeration tubing is not rubbing or vibrating

against other tubing, panels, etc.

Do not put anything (boxes, etc.) on the sides or back of

the ice machine. There must be adequate airflow

through and around the ice machine to maximize ice

production and ensure long component life.

Exterior Cleaning

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation. Use cleaners designed for use with stainless

steel products.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, soft cloth.

Heavy stains should be removed with stainless steel

wool. Never use plain steel wool or abrasive pads. They

will scratch the panels.

Cleaning the Condenser

GENERAL

A dirty condenser restricts airflow, resulting in

excessively high operating temperatures. This reduces

ice production and shortens component life. Clean the

condenser at least every six months.

Shine a flashlight through the condenser to check for dirt

between the fins. To remove dirt:

A. Blow compressed air or rinse with water from

the inside out (opposite direction of airflow). Be

careful not to bend the fan blades.

B. Use a commercial condenser coil cleaner if

required to remove dirt/grease. Follow the

directions and cautions supplied with the

cleaner.

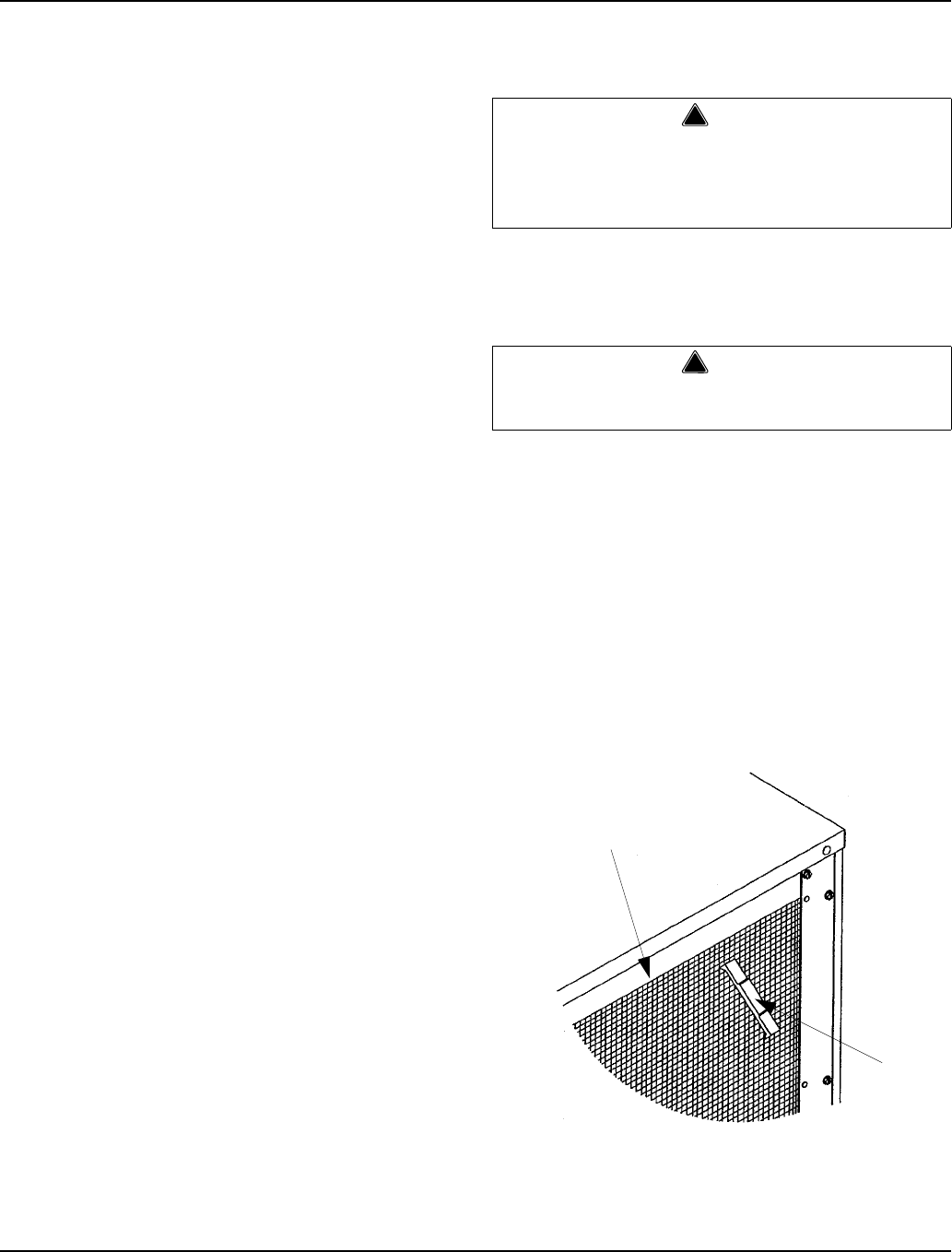

C. Straighten any bent condenser fins with a fin

comb.

Straighten Bent Condenser Fins

!

Warning

Disconnect electric power to the ice machine head

section and the remote condensing unit at the

electric service switches before cleaning the

condenser.

!

Warning

The condenser fins are sharp. Use care when

cleaning them.

SV1515

FIN

COMBS

CONDENSER

“COMB” DOWN

ONLY