22

SECTION 2

INSTALLATION

E. Adjusting the Minimum Pressure Setting

1. Disconnect pressure feedback connection (if appcable).

2. Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

3. Disconnect electrical connection of the Moduplus

®

.

4. Energize operator, set control in operation and wait until

an outlet pressure is recorded on pressure gauge.

5. If minimum rate pressure needs adjustment, use an 8 mm

wrench to turn adjustment screw for minimum pressure

setting (clockwise to increase or counter-clockwise to

decrease pressure), until the desired minimum outlet

pressure is obtained.

6. Check if main burner lights easily and reliable at mini-

mum pressure.

7. Reconnect pressure feedback connection (if appcable).

8. Close pressure tap screw.

F. Checkout

After any adjustment, set appliance in operation and

observe through a component cycle to ensure that burner

system components function correctly.

Gs. Maintenance

It is recommended to check yearly the minimum and the

maximum setting and readjust them if necessary.

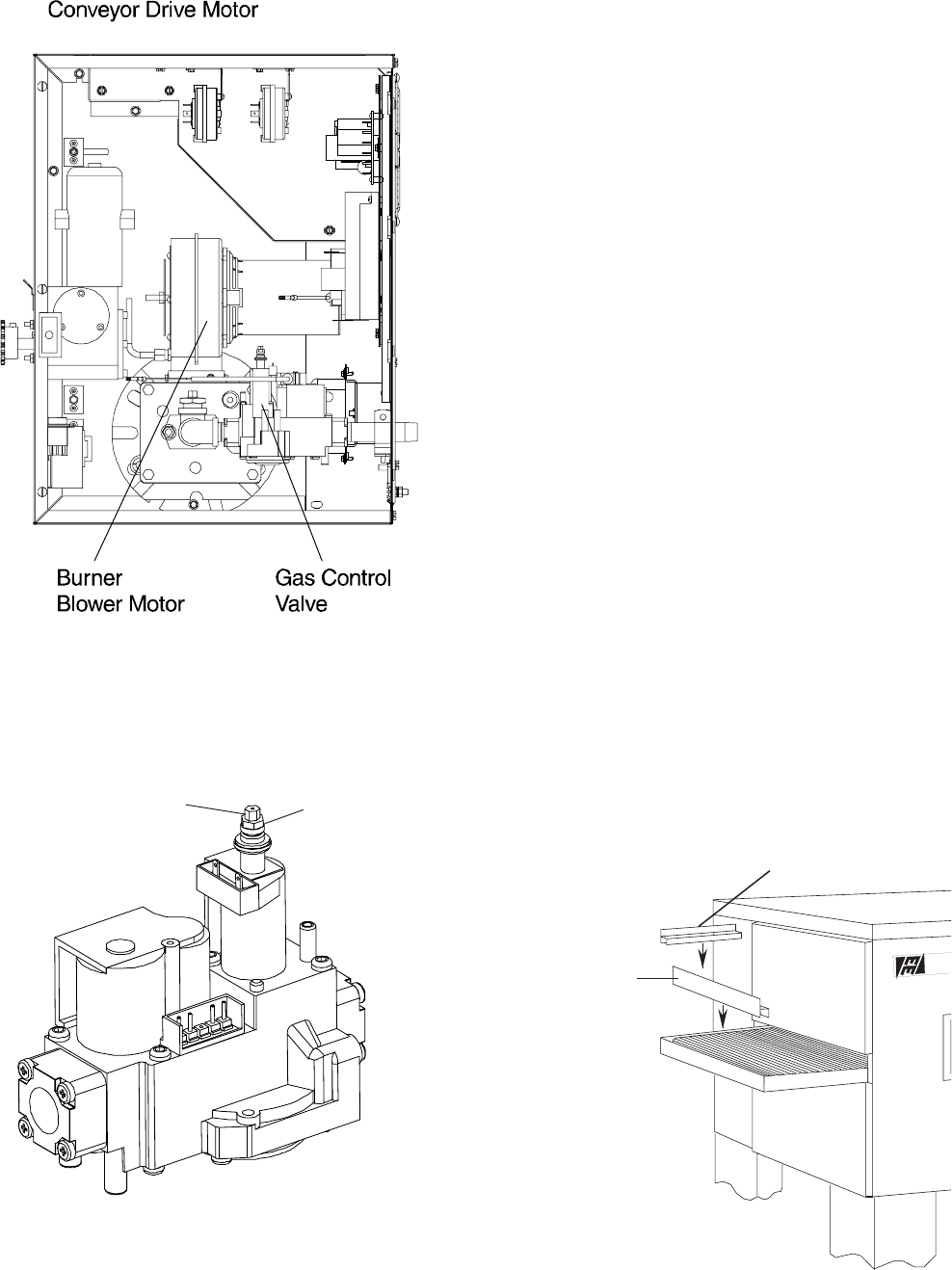

Figure 2-15. Burner Assembly

Figure 2-16. Gas Valve

Adjustment Screw (5 mm)

for minimum pressure

setting

Adjustment Screw

(8 mm) for maximum

pressure

setting

VI. CONVEYOR REAR STOP AND END

STOP INSTALLATION

Locate the conveyor rear stop and end stop in the

installation kit. Install the rear stop and end stop at the exit

end of the oven. See Figure 2-17.

M

id

d

l

e

M

a

r

s

h

Conveyor Rear Stop

Conveyor End Stop

Figure 2-17. Installing Rear and End Stops