PAGE 20 — MVH-200DA PLATE COMPACTOR — OPERATION & PARTS MANUAL — REV. #0 (03/21/05)

MVH-200DA — MAINTENANCE

Inspection and Maintenance Service Tables.

To make sure your plate compactor is always in good working

condition before using, carry out the maintenance inspection in

accordance with Tables 5 through 7.

Daily Service

z

Check for leakage of fuel or oil.

z

Check for loose screws including tightness. See Table 7

below (tightening torque ), for retightening:

z

Remove soil and clean the bottom of compaction plate.

z

Check hydraulic pump, piping and hose for any leakage. A

loosened hydraulic hose can be a cause for leakage. Check

hydraulic hose connections with wrench applied for

tightness.

z

Check engine oil.

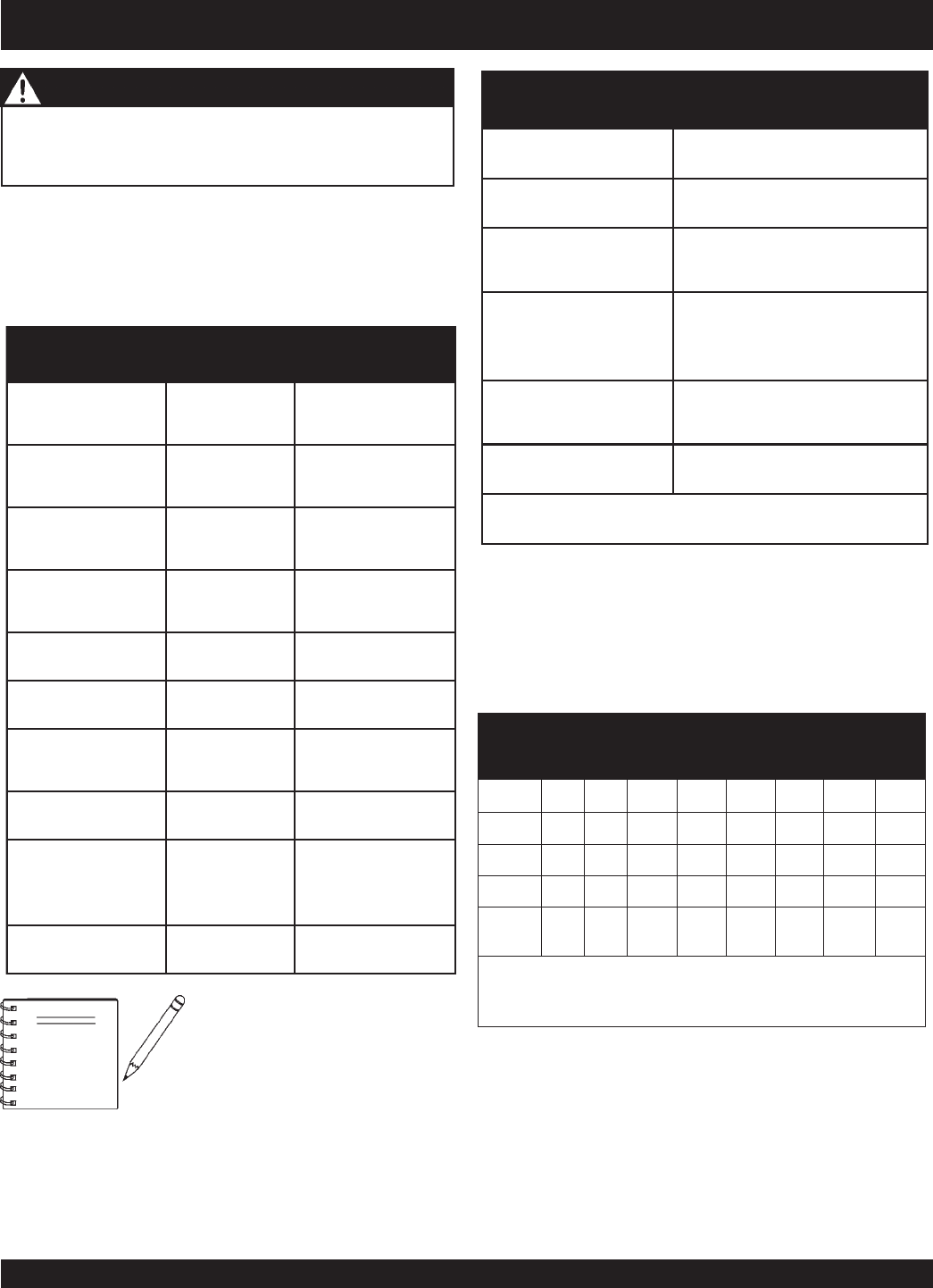

.7ELBAT

retemaiD)mc/gk.ni(EUQROTGNINETHGIT

lairetaM

mm6 mm8 mm01 mm21 mm41 mm61 mm81 mm02

T4 07 051 003 005 057 001,1 004,1 000,2

T8-6 001 052 005 008 003,1 000,2 007,2 008,3

T11 051 004 008 002,1 000,2 009,2 002,4 006,5

* 001

~003

053

~056

007

)munimulafositrap-retnuocesacnI(*

)dednahthgirllaeraenihcamsihthtiwesunisdaerhT(

.wercsdna,tlobhcaenode

kramsilairetamfoytilauqdnalairetaM

AD002-HVM.5ELBATNOITCEPSNIENIHCAM

METI

FOSRUOH

NOITAREPO

SKRAMER

gnissiMroesooL

swercS

sruoh8yrevE

)yadyreve(

straPdegamaD

sruoh8yrevE

)yadyreve(

gnillortnoCfonoitcnuF

traPmetsyS

sruoh8yrevE

)yadyreve(

kaeLmetsySciluardyHsruoh001yrevE

kcehCliOrotarbiVsru

oh001yrevE12egapeeS

liOrotarbiV

tnemecalpeR

sruoh003yrevE12egapeeS

kcehCliOciluardyHsruoh001yrevE32egapeeS

liO

ciluardyH

tnemecalpeR

002retfatsriF

yreveneht,sruoh

sruoh000,1

32egapeeS

kcehC)hctulc(tleb-Vsruoh002yrevE22eg

apeeS

AD002-HVM.6ELBATKCEHCENIGNE

METINOITAREPOFOSRUOH

kaeLleuFroliO)yadyreve(sruoh8yrevE

gninetsaFfossenthgiT

sdaerhT

)yadyreve(sruoh8yrevE

d

nakcehCliOenignE

tnemhsinelpeR

)yadyreve(sruoh8yrevE

mumixamdeificepsothsinelpeR(

)level

tnemecalpeRliOeni

gnE

ot05yrevenehtsruoh52tsrifretfA

sruoh001

gninaelCretliFriAsruoh001yrevE

.kcehcenignenosliatedroflauname

nigneetarapeseeS

These inspection intervals are for

operation under normal conditions.

Adjust your inspection intervals

based on the number hours plate

compactor is in use, and particular

working conditions. Fuel piping and

connections should be replaced

every 2 years.

Inspection and other services should

always

be carried out

on hard and level ground with the engine shutdown.

CAUTION - General Maintenance Safety

NOTE