5

INSTALLATION

Installation of filter should only be done by qualified, li-

censed personnel.

Filter Assembly

Filter mount must:

• Be solid, level, rigid, vibration free, and provide for ad-

equate drainage.

• Be as close to pool as possible to reduce pressure loss

from pipe friction.

• Provide weather and freezing protection.

• Provide adequate ventilation to prevent motor from

overheating.

• Provide space and lighting for easy access for servicing

pump and piping (See Figure 1, Page 4, for space

requirements).

Piping (See Figure 1B for correct connections):

NOTICE: Make sure that the filter and all piping can be

drained for winterizing. See “Winterizing”, Page 9.

• Piping must conform to local/state plumbing and sani-

tary codes.

• Use teflon tape, Plasto-Joint Stik

®1

, or Silastic RTV

#732

®

on all male connections of plastic pipe and fit-

tings. DO NOT use pipe compounds on plastic pipe; it

will cause the pipe to crack. Do not use sealant on

unions – assemble them dry and hand tight.

• Support pipe independently to prevent strains on filter.

• Fittings restrict flow; for best efficiency use fewest pos-

sible fittings.

• For ease of maintenance, Sta-Rite union couplings are

provided to connect the piping to the filter inlet and

outlet ports.

• Keep piping tight and free of leaks: pump suction line

leaks may cause trapped air in filter tank or loss of

prime at pump; pump discharge line leaks may show

up as dampness or jets of water.

• NOTICE: Overtightening can crack filter ports.

Valves:

• A check valve installed ahead of filter inlet will prevent

contaminants from draining back into pool.

• A check valve installed between filter and heater will

prevent hot water from backing up into filter and de-

forming internal components.

• For installation allowing backwashing, install Sta-Rite

Two Position Slide Valve or Multiport Selector Valve

with filter. See Table 3. If you intend to clean your filter

according to “Module Cleaning Procedure”, Page 7, no

slide or multi-port valve is required. See Figure 1B,

Page 4, for correct water flow when connecting pipe.

• Filter ports and valve ports are furnished with union

connections. DO NOT use pipe sealants on union col-

lar (nut).

1

Lake Chemical Co., Chicago, IL

• Use care before assembly not to damage union sealing

surfaces or O-Ring.

• To allow recirculation during precoat (if precoat pot is

used), install a recirculation line with shut-off between

pad return line and pump suction.

Electrical:

• BE SURE filter grounding and bonding meets local and

National Electrical Code standards. All wiring, ground-

ing and bonding of associated equipment must meet

local and National Electrical Code Standards.

INITIAL START-UP

Be sure pump is OFF

before starting procedure.

Do not operate these filters at more than 50 PSI

(345 kPa) under any circumstances!

To prevent serious damage to the element

fabric, NEVER run your DE filter without a

diatomaceous earth precoat!

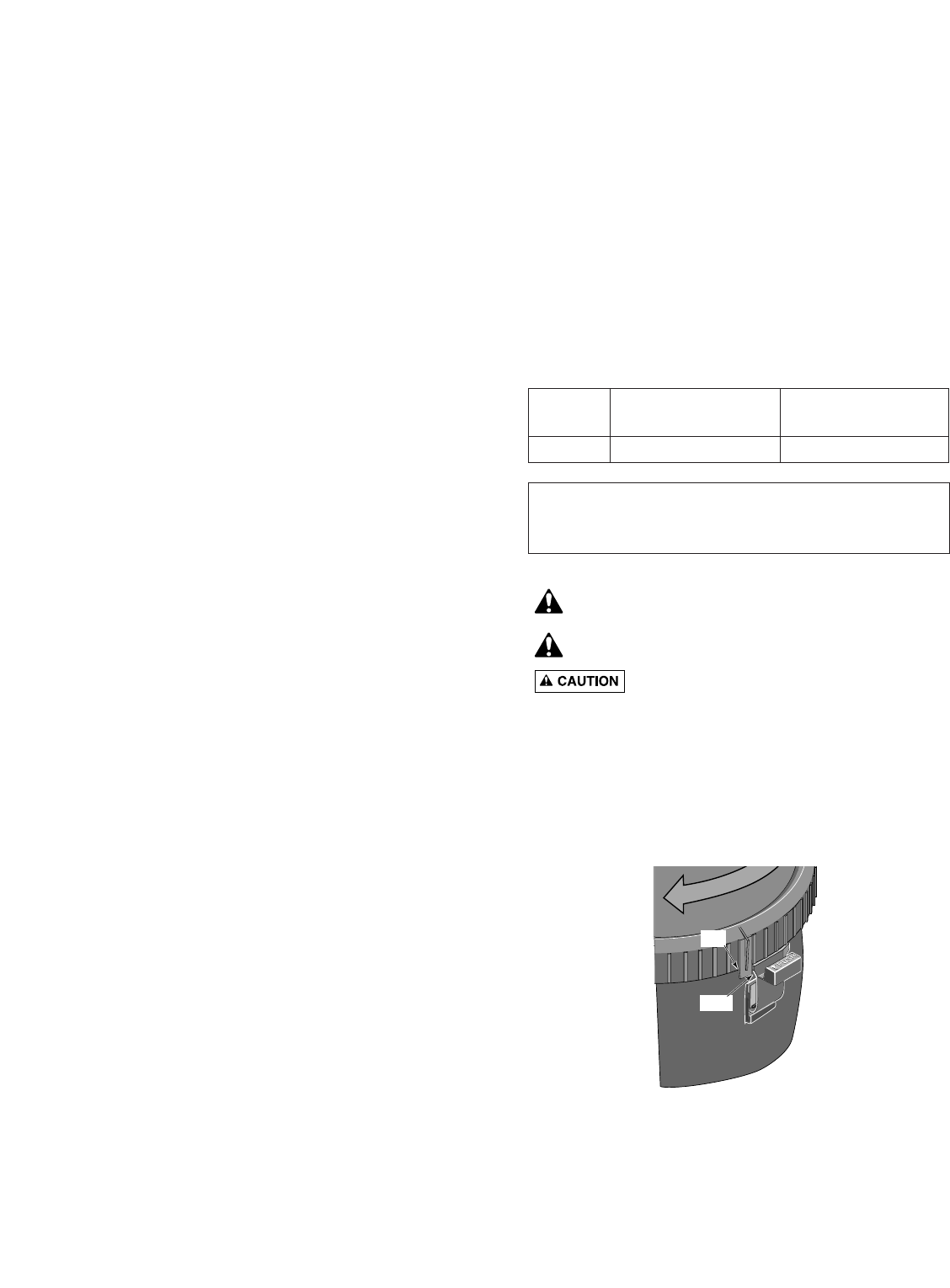

1. Securely lock Posi-Lok™ ring in place by rotating ring

CLOCKWISE until it “clicks” past the safety latch (see

Figure 3). Stop turning as soon as the ring clicks past the

latch. The ring may feel slightly loose, but it will tighten

up when pump is on and filter is under pressure.

2. Fill trap on pump with water.

3. Open air release valve on top of filter.

4. Open isolation valves.

5. Start pump to purge air from system.

6. When steady stream of water comes from air release

2149 1195

Latch

Tab

Figure 3 – Rotate Posi-Lok™ Ring until tab locks

behind the safety latch.

Port Multi-port Valve Plastic Slide Valve

Size Part Number Part Number

2" 18201-0300 14935-0300

TABLE 3 - Sta-Rite valves for use with Model PLDE36

and PLDE48 filters

NOTICE: Use of valves other than those listed above

could cause reversed water flow through filters and

damage to internal filter components.