Medical Package System

4

Specifications

Medical Package Duplex – Model MPD

Medical Package Triplex – Model MPT

Medical Package Quadplex – Model MPQ

MODEL HP PHASE RPM VOLTAGE

MPD0508 5(2) 3 33.4 36.2 870 208/230/460 17.4 /16.5 /8.2 120 64 x 65 x 76 1288

MPD0758 7.5(2) 3 52.2 55.1 840 208/230/460 23.4 / 22 /11 120 64 x 65 x 76 1340

MPD1008 10(2) 3 70 76.3 1070 208/230/460 29 /33 /16.5 200 64 x 65 x 80 1510

MPD1508 15(2) 3 108.4 114.1 1250 208/230/460 51/ 48 /24 200 64 x 65 x 80 1630

FULL LOAD AMP/

MOTOR

SCFM

@

100 PSIG

SCFM

@

50 PSIG

GALLON

TANK

DIMENSION

LxWxH

SHIPPING

WT. (Lbs.)

MODEL HP PHASE RPM VOLTAGE

MPT0508 5(3) 3 50.1 54.7 870 208/230/460 17.4 / 16.5/ 8.2 200 96 x 65 x 80 1838

MPT0758 7.5(3) 3 78.8 83.9 840 208/230/460 23.4 / 22 / 11 200 96 x 65 x 80 1980

MPT1008 10(3) 3 105 111.5 1070 208/230/460 29 / 33 / 16.5 240 96 x 65 x 92 2160

MPT1508 15(3) 3 162.6 168 1250 208/230/460 51/ 48 /24 240 96 x 65 x 92 2280

FULL LOAD AMP/

MOTOR

SCFM

@

100 PSIG

SCFM

@

50 PSIG

GALLON

TANK

DIMENSION

LxWxH

SHIPPING

WT. (Lbs.)

MODEL HP PHASE RPM VOLTAGE

MPQ0508 5(4) 3 66.8 74.9 870 208/230/460 17.4/ 16.5/ 8.2 240 128 x 65 x 92 2388

MPQ0758 7.5(4) 3 104.4 120.2 840 208/230/460 23.4 / 22/ 11 240 128 x 65 x 92 2490

MPQ1008 10(4) 3 140 153 1070 208/230/460 29 / 33 / 16.5 240 128 x 65 x 92 2640

MPQ1508 15(4) 3 216.8 221 1250 208/230/460 51 / 48 / 24 240 128 x 65 x 92 2735

FULL LOAD AMP/

MOTOR

SCFM

@

100 PSIG

SCFM

@

50 PSIG

GALLON

TANK

DIMENSION

LxWxH

SHIPPING

WT. (Lbs.)

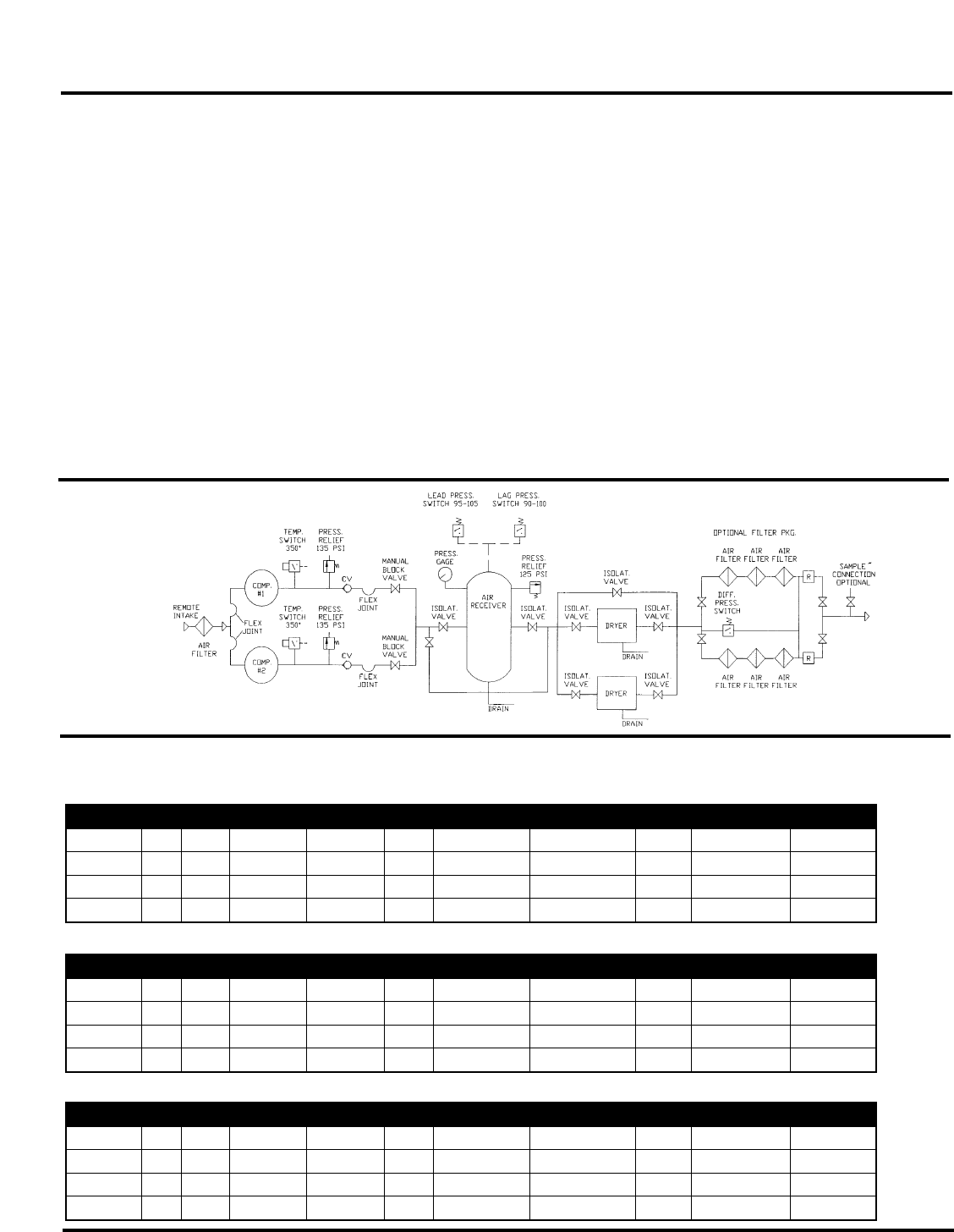

Medical

Air Schematic

BEFORE START UP

1. Make sure all safety warnings, labels

and instructions have been read and

understood before continuing.

2. Remove any shipping materials,

brackets, etc.

3. Confirm that the electric power

source and ground have been firmly

connected.

4. Be sure all pressure connections are

tight.

5. Check to be certain all safety relief

valves, etc., are correctly installed.

6. Check that all fuses, circuit breakers,

etc., are the proper size.

7. Make sure the inlet filter is properly

installed.

8. Confirm that the drain valve is closed.

9. Visually check the rotation of the

compressor pump. If the rotation is

incorrect, have a qualified electrician

correct the motor wiring.

START-UP AND OPERATION

1. Follow all the procedures under

“Before start-up” before attempting

operation of the compressor.

2. Switch the electric source breaker

on.

3. Both dryers should be plugged in

and set at the on position.

4. Dewpoint & CO Monitors should be

on and the sampling valves open.

Calibrate Dewpoint and CO per

enclosed manufacturer’s

instructions.

5. Ensure water lines are properly

installed to water-cooled

aftercoolers. Turn on water.

IMPORTANT: This is not a standard

option. Check to see if water-

cooled aftercoolers were provided.

6. Compressor unit isolation valves are

preset at the factory in the open

position except for tank by-pass

which must remain closed during

normal operation.

7. Dryer and filter isolation valves:

Valves should be open to one dryer

and one filter bank.

8. Close valve leading to the Medical

Air System from receiver on the

compressor unit.

a. Turn both fusible/breaker

disconnects to the on position.

Low pressure alarm will sound.

Silence the alarm by pushing alarm

acknowledge button.

b. Jog each compressor in the manual

position on the selector switch to

check for rotation. (Clockwise if