5

Oilless Reciprocating Air Compressor Pumps

Valve Inspection/ Replacement (Inspect Every 5,000 Hours)

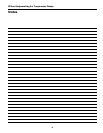

INSPECT VALVE SET

1. Remove head bolts from cylinder

head. Head bolts for some models

are used also as cylinder bolts, which

penetrates crankcase (See Figure 7).

2. Remove cylinder head and valve set.

If it is difficult to remove by hand,

insert screwdriver between cylinder

and valve set and remove.

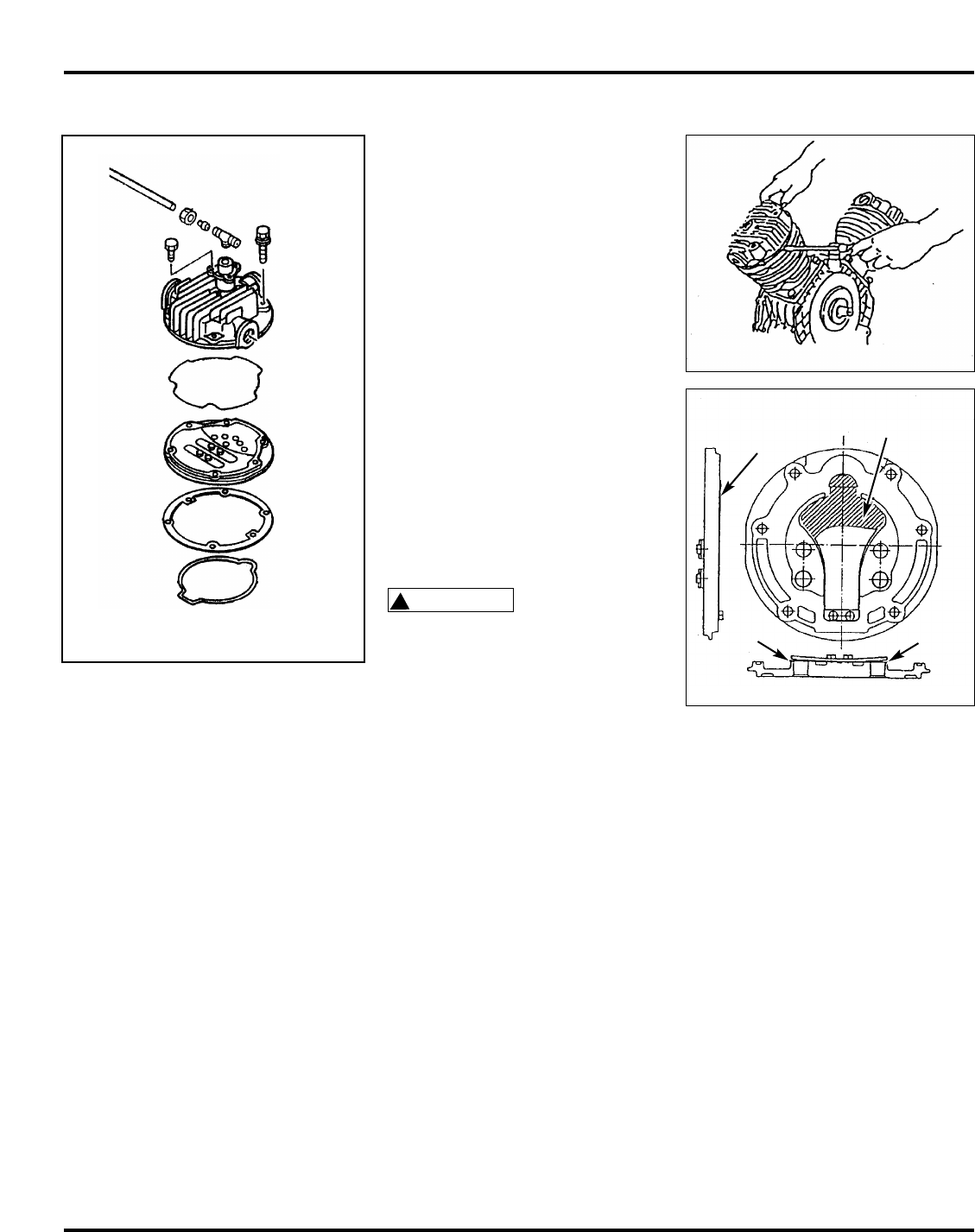

INSPECTION AND MAINTENANCE

1. Check if exhaust valve (A) sticks to

seat or is damaged (See Figure 8).

2. Check if there is breakage, gouge or

damage to appearance of intake

valve (B).

3. Lift intake valve by 10 mm and

check if there is peeling and wear

on coating surface of valve spacer

(C).

Lifting intake

valve too much can

cause damage to intake valve.

4. Replace with intake valve if valve

plate and valve spacer are worn or

wear is over 0.5 mm in depth. If

exhaust valve rises upwards, clean

seat surface if foreign matter sticks.

5. Clean the whole valve set taking care not to damage, seat surface and remove

dust.

6. If viton seals (upper and lower) reach inspection time, replace them. Even if its

not time to inspect, be sure to replace if they do not protrude from groove for

seal or seal has hardened or been damaged.

7. Be sure to replace plastic seat in cylinder.

8. Fit valve set while paying attention to black plastic seat of intake valve fitted to

cylinder (so that you do not drop seat or insert tip of valve under seat).

9. Fit cylinder cover and tighten fitting bolt with designated torque.

NOTES:

• When using valve set again, replace upper and lower viton seals.

• When replacing valve set, replace with upper and lower viton seals (valve set

with packing set). You cannot reuse disassembled valve set.

We are not responsible for any problems caused by reuse of disassembled valve

set.

REASSEMBLY

Assemble in reverse order of disassembling. Tighten each section with designated

tightening torque (See Chart on page 6).

!

CAUTION

(B)

Check for peeling

or wear (C)

(A)

(A)

Figure 6

Figure 7

Figure 8