AIR RECHARGING IN COMPRESSOR

Test the refrigeration system by connecting it electrically

before refilling operation. This is necessary to ascertain the

function of the motor-compressor and identify the defects

immediately. If the defects have been found, empty the old

system of eventual R134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an extension completely with male Hansen and

last, solder it to the same tube again. (Figure 2)

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowholes between two tubes

during heating the point to be soldered.

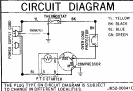

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

Air evacuating from the system begins as soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 atm., -760 mm Hg) in any

case it is advisable to keep the pump running for about

60 minutes. (Figure 4)

POINT TO BE

BROKEN

SERVICE TUBE

EXTENSION

Figure 1

CHARGE TUBE FEMALE

EXTENSION HANSEN

MALE

HANSEN

SOLDERING

POINT

Figure 2

MP

PRESSURE

GAUGE

Figure 3 Figure 4

-5-