5

fans, used on larger models, include hollow GRE (glass-

reinforced epoxy) blades and epoxy-coated cast iron hubs.

Blades on both fan types are adjustable in pitch, so you can

take full advantage of rated horsepower or adjust the pitch

to compensate for unusual job site restrictions. The true

airfoil blades, designed specifically for cooling towers, offer

efficient, quiet operation and long service life.

Mechanical Equipment

You’ll receive a 5-year warranty against failure of any

mechanical component in the fan drive system (except the

motor, which is warranted by its manufacturer).

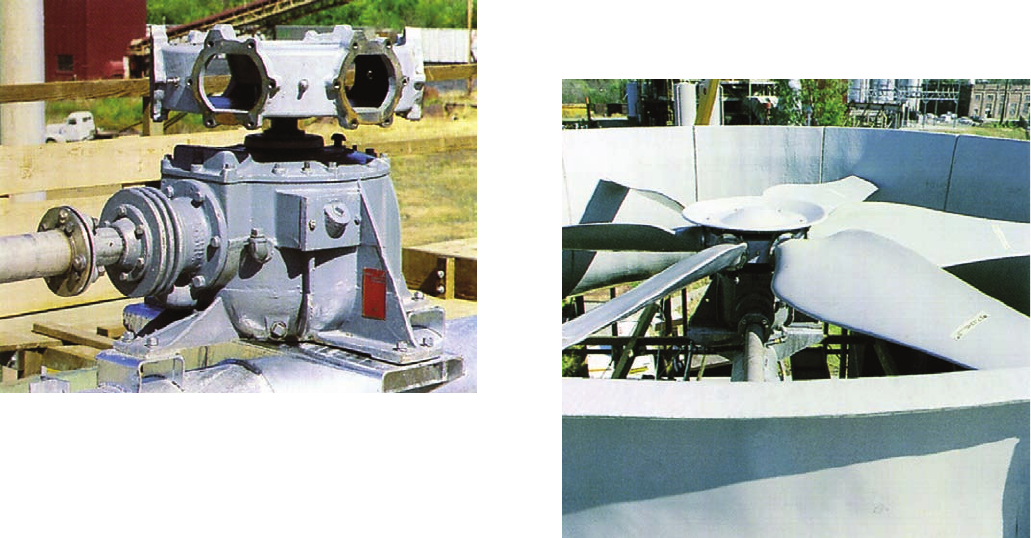

The Marley Geareducer speed reducers used in the

Sigma line contribute a long record of dependability, long

service life, and low maintenance to this assurance of

reliability. Their designs meet or exceed the requirements

of CTI STD-111 and AGMA Std. 420.04. We run-in every

Geareducer unit under load prior to shipment to make sure

that it will operate properly on your tower.

Housings are gray cast iron. Gears are high-strength,

case hardened alloy steel. And all bearings are tapered roller

bearings. A variety of available horsepower capacities and

reduction ratios lets us choose the optimum Geareducer

model and fan speed for your job. Service factors are always

at least 2.0 as applied.

Splash-type lubrication and integral cooling fins preclude

the need for maintenance-intensive oil pumps and coolers. A

constant oil bath or flow lubricates every bearing in forward or

reverse motion – at full or half speed.

All Marley Geareducer assemblies are right-angle type

with motors located outside the tower’s saturated airstream.

A galvanized steel lube line runs from the Geareducer unit

to a standpipe near the motor on each cell, so you can check

oil level and change or add oil while standing on the fan deck.

All Sigma Series 1000/1200 towers offer the benefits of

adjustable pitch propeller type Marley fans. The H-3 series

fans normally used on smaller models incorporate cast

aluminum blades and machined aluminum hubs. HP-7 series

Fans operate inside structural GRP (glass-reinforced

polyester) eased-inlet fan cylinders designed and applied to

maximize fan performance. Cylinder height varies from 3'-5"

to 7'-0", depending on fan diameter. Cylinders less than

6'-0" tall include galvanized welded fan guards. (See Access

and Safety on page 7.)

Marley-manufactured driveshafts transmit power

from the motor to the Geareducer assembly. All Marley

driveshafts include 304 stainless steel tubes with welded-

on stainless steel flanges and bonded neoprene flexible

elements to transmit torque. Marley driveshafts are full-

floating assemblies with non-lubricated flexible couplings

on each end. Their tolerance to misalignment and torsional

shock is unequalled in nonspecialized units. All Marley

driveshafts are dynamically balanced at the factory to

minimize operating vibrations.

Welded unitized hot-dip galvanized steel supports

maintain alignment throughout the mechanical equipment

system. Marley torque-tubes provide superior strength and

stability. Their cylindrical shape also keeps operating costs

down by minimizing airflow restrictions and reducing air

turbulence in the fan entrance region.

/ Construction and Components /