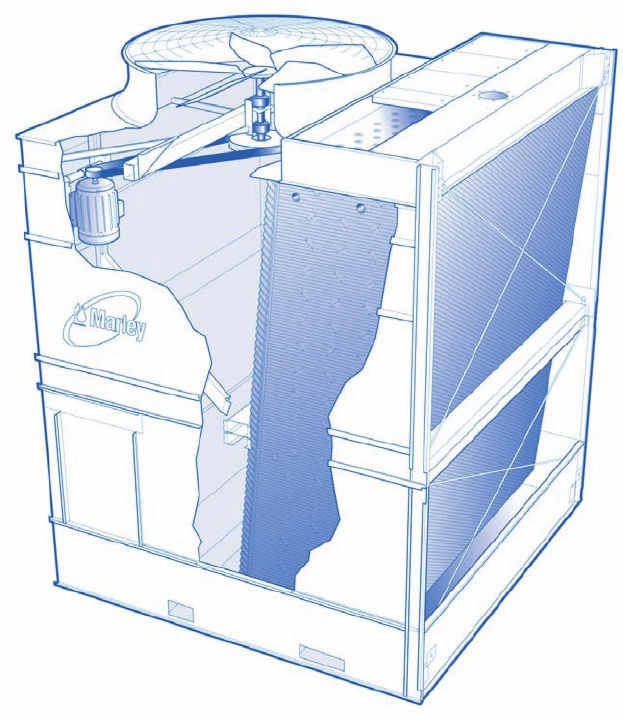

AV Air Movement System

n Streamlined eased inlet fan cylinder

assures full area, low turbulence airflow

through the cylinder.

n Heavy duty aluminum alloy fan–

adjustable pitch blades.

n 7.5 hp and larger fans are driven by a

high quality, solid backed, multi-grooved

neoprene and polyester v-belt thru a

corrosion resistant aluminum alloy fan

sheave.

n Heavy duty, self-aligning, grease

lubricated roller bearings selected with

an L

10

design life of 50,000 to 100,000

hours support the fan and shaft.

n TEFC fan motor, 1.15 service factor,

variable torque design, specially insulated

for cooling tower duty.

n The AV air movement system is

guaranteed against failure for a period

of five full years from date of shipment.

Includes fan, fan shaft, bearings and

mechanical equipment support.

Note: For economical transportation, AV towers are also

available unassembled and crated for export.

For Safety Reasons —always shut down and lock out the

fan motor before entering the plenum.

/

Features

/

AV Water Distribution System

n Gravity flow distribution system. Easy, nonrestrictive

maintenance. Basin covers are standard.

n Marley Spiral Target polypropylene nozzles for

consistent, predictable water distribution.

n Marley MX thermoformed PVC film fill is suspended

from the upper tower structure by heavy galvanized

steel support members providing clearance between fill

and sloping self-cleaning collection basin floor for easy

basin cleaning. Integral eliminators and louvers keep

circulating water confined to fill over a wide range of air

flow rates.

AV Structure

n Crossflow configuration — easier and safer to inspect,

service and maintain.

n G-235 heavy galvanized steel. Also available in 300

stainless steel.

n Factory-assembled modules, including fan cylinders

— makes final field installation hassle-free.

n Large Access Doors—the generous plenum region in

the AV tower is nonconfining, permitting quick visual

inspection of cold water basin, internal structure, drift

eliminators and mechanical equipment.