TP03 User Manual ◄ 13

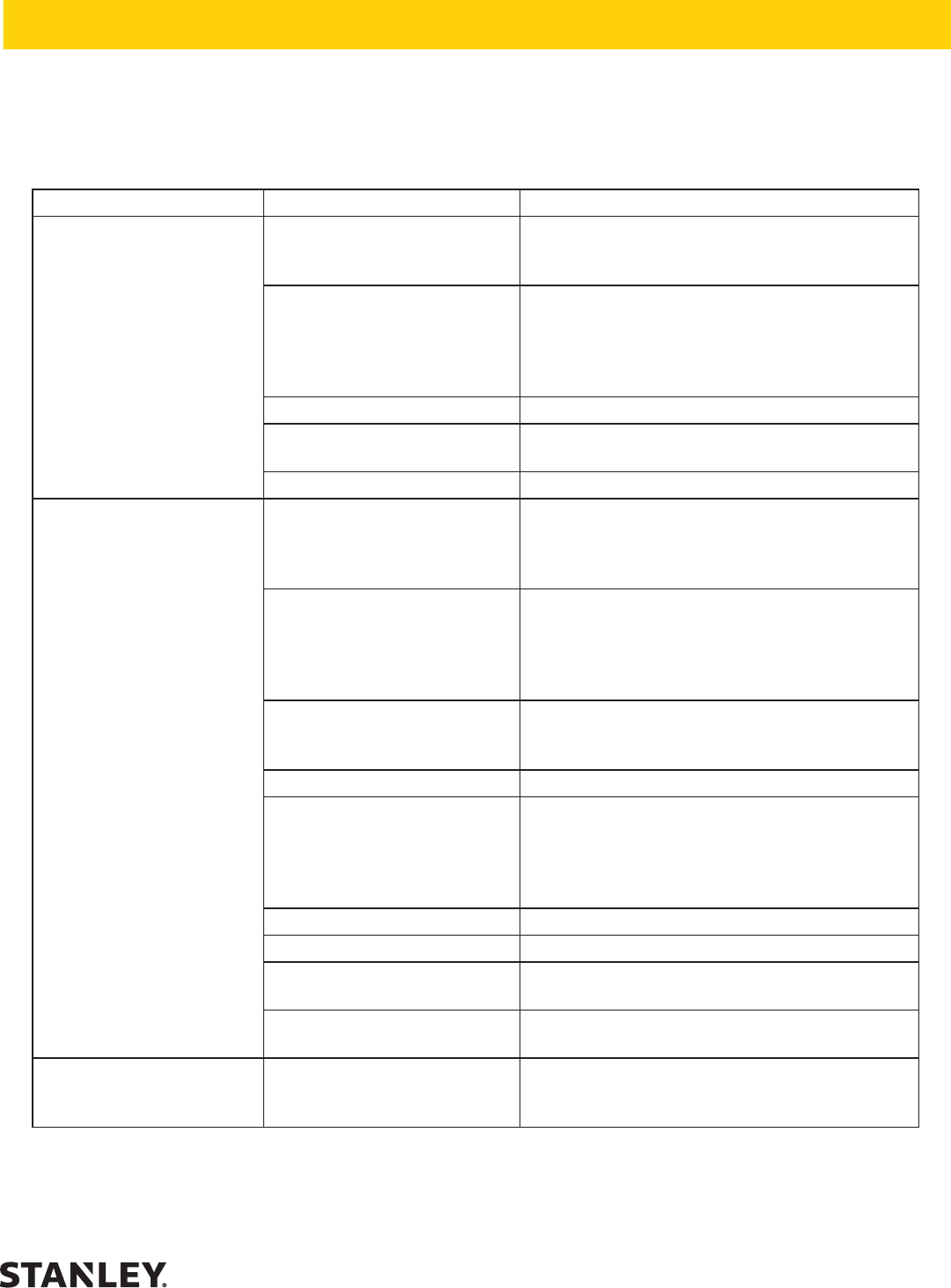

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the tool, always make sure the hydraulic power source is supplying the cor-

rect hydraulic ow and pressure as listed in the table. Use a owmeter know to be accurate. Check the ow with the

hydraulic uid temperature at least 80 °F/27 °C.

PROBLEM CAUSE SOLUTION

Pump will not start. No hydraulic uid ow or

pressure.

Turn on power unit and check that 7–9 gpm/26–

34 lpm at 1500–2000 psi/105–140 bar is

available at the trash pump.

Defective couplers. Check the couplers by connecting them together

with the hydraulic power supply operating and

with the control valve in the “ON” position. The

power supply should operate without “loading”

from the couplers.

Impeller jammed with debris. Clean the pumping chamber.

Impeller rubbing against wear

plates.

Check and adjust the impeller clearance.

Defective power module. Repair or replace the power module.

Poor pump performance. Hydraulic ow reversed. Check that the hoses are correctly connected to

the pump motor ports. The female coupler should

be connected to the “IN” port. The return uid

must never ow through a reversing valve.

Improper hydraulic uid ow. Check that 7–9 gpm/26–34 lpm at 1500–2000

psi/105–140 bar is available at the trash pump.

A 20% decrease in ow can result in a 50%

decrease in pump performance. 8 gpm/30 lpm is

the best circuit ow.

Trash pump submersed in

sediment.

Lift the pump from the bottom of the hole or

chamber. Use a at support under the pump if

necessary.

Trash pump inlet restricted. Remove restriction and thoroughly clean.

Discharge hose kinked or

restricted.

Straighten the hoes. If the hose must bend at the

top of the hole, use a piece of split rigid conduit

with large diameter of the expanded hose. This

keeps the hose from kinking. Use a 90° 3-inch

pipe elbow on the trash pump outlet if necessary.

Discharge hose too small. Use a 3-inch diameter hose.

Water lift too high. Lower the outlet end of the discharge hose.

Impeller worn or damaged. Check impeller for damage and excessive wear.

Replace if necessary.

Wear plates worn or damaged. Check wear plates for damage and excessive

wear. Replace if necessary.

Hydraulic uid in discharge

ow.

Motor shaft seal failure. Replace the motor shaft seal.

Ensure power unit is delivering 7–9 gpm/26–34

lpm

TROUBLESHOOTING