4

www.thermastor.com • sales@thermastor.comToll-Free 1-800-533-7533

2.4 Hanging the Quiet-Vent

The Quiet-Vent has four vibration absorbing straps for

hanging from joists, rafters, or trusses (See Fig. 1 & 3)

and use (4) 1/4” diameter lag bolts or the equivalent.

Locate the unit to minimize the ducting from the baths and

kitchen to the Quiet-Vent inlets and from the Quiet-Vent

outlet to the outside. Because the oiling system depends

on gravity, the unit must be oriented with the hanger bolts

on the top.

2.5 Ducting to and from the Quiet-Vent

All flexible ducting connected to the unit should be UL

listed. The preferred method of ducting the exhaust air

from the rooms is to use 4” round duct from 4” x 6”

register heads located in the wall cavities or the ceiling.

For routing through 3.5” stud cavities, flatten the 4”

round duct to 3.25”. If a 4” duct length from a full bath

or kitchen exceeds 50’, two 4” ducts or a 6” duct is

recommended. The 4” duct can be either metal or flexible

and can be routed to the Quiet-Vent 4” inlet or manifolded

to a 6” duct. If more than four 4” ducts are connected to

the Quiet-Vent, use a 6” manifold on the Quiet-Vent’s 6”

inlet.

DO NOT locate the register head connecting the kitchen duct to

the Quiet-Vent in the area designated in Fig. 5.

To exhaust the stale air, connect a six inch insulated

flexible duct from the outlet of the Quiet-Vent to a

dampered six inch wall cap. If the length of the exhaust

duct exceeds 50 ft., an 8” duct should be used. All the

ducts must be insulated when they are located in non-

heated space in a cold climate. Flexible duct can be

spliced by threading the ends of the ducts into each

other 3 turns. To reduce leakage, all the duct couplings

should be taped with 3 turns of duct tape. Several ducting

alternatives are illustrated in Fig. 3.

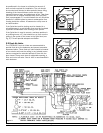

2.6 Wiring the Quiet-Vent

NOTE: All electrical connections must be installed by a qualified

electrician. All wiring must conform to the local electric codes

and/or the National Electrical Code.

Quiet-Vent uses a 115 volt, 10 amp circuit which is

connected to the black and white wires in the electrical

cabinet (see Fig. 4). Spring wound one hour remote timers

or humidity controllers located in the baths and kitchen

are wired in parallel to the two blue wires. These remote

controls activate the high speed of the exhaust fan. These

controls are to be UL listed with minimum electrical ratings

of 2 amps inductive load at 125 VAC.

The prewired 7 day timer located on the Quiet-Vent

activates the low speed of the exhaust fan. The timer can

be mounted remote from the Quiet-Vent. This requires a

double gang electrical box and 3 conductors plus ground

to extend connections to the timer from the Quiet-Vent.

A 4” junction box cover is used to cover the timer opening

on the Quiet-Vent.

Figure 5

Figure 4

Alternative Electrical

Layouts

Circuit to next timer in bath or kitchen

Timer switch ground

115 Volt circuit/ground from

Quite-Vent to bath or kitchen

10-15 AMP 115 Volt

circuit with ground from

main electrical service

Timer switch

ground

Cooking Area

Do Not Install Above or Inside

This Area

Cooking

Equipment

45° 45°

Floor