VI.

CALIBRATION

OF TIIE

POTENTIOMETER

A. Ttoubleshooting

Calibration

of the

potentiometer

is

necessary

only

after replacement

of the

controller

or

if

the

calibra-

tion

plate

should become

jarred

loose

from

its

factory

calibrated position.

The allowable

temperature

range

of the

gdddle

is

15CPF(65'C)

to

450'F(230.C)

for

each zone.

Within

this temperature

paftrmeterthe

temperature

should

fluctuate

no

more than

+14"F(j'C)

from the

set

point

temperature.

B.

Calibrating

Procedure

Note:Before

making

any calibration

adjustments,

the

griddle

should

be

up

to

temperature

and cycling

and all

panels

including

the front

control

panel

must

be in

their closed position-

Calibrating

the

griddle

with any

of the

panels

open

will

allow

for a

cooler

junction

temperature

at

the connectiorrpoiniof

the

thermocouple

at

the control.

This

may

give

an

inaccurate

indication.

Keeping

the

panelsrclosed

will

provide

for

a more

accurate

calibration

even

though

the

control

does

provide

an ice

point

reference

(calibration)

as

indicated

in

Appendix

A.

A

good

tvpe

K temperature

indicator

source

must

be

used

when

taking

temperature

readings

off

the

griddle

surface for

calibration

adjustrnents.

Proper

place-

ment of

the thermocouple

test

probe

is

cmcial.

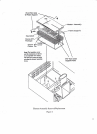

See Figure

8 for

proper probe

placement

on thr

griddle

surface.

When taking

the temperature

of the

griddle,

the

temperature

probe

should be

placed

at the center

of the

griddle

surface

OF THAI ZONE.

The

temperature

probe

should

be

held down

by an aluminum weight

with

a

piece

of

high

temperature

insulation

(1000

degrees

C) between

the

probe

and

the

weight.

This

combination

helps

to aquire

the most

accurate

readings

possible

without the

weight

absorbing

tempera-

ture

from

the

probe.

1) Determine if

the temperature

of

the center

of

the

griddle

surface

for

that zone

is more than

+14.

F(7"C) above

or

below the

set

point

of 350"F(175"C).

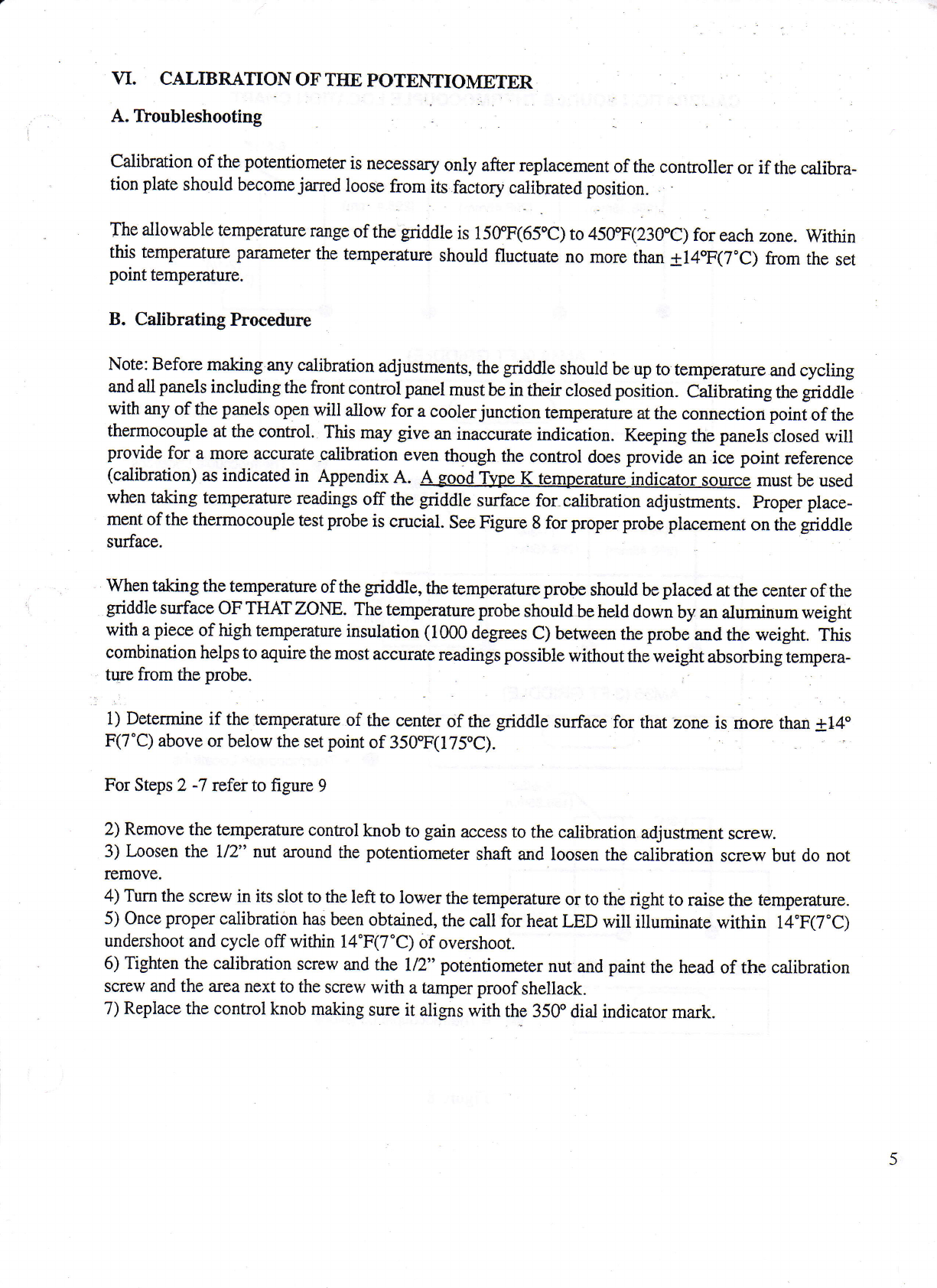

For Steps 2

-7

refer

to figure

9

2) Remove

the temperature

control

knob

to

gain

access to

the calibration

adjustment

screw.

3)

Loosen

the L/2" nut

around

the

potentiometer

shaft and loosen

the calibration

screw but do not

remove.

4)

Turn the

screw in its

slot to

the left

to lower

the

temperature

or to the

right

to raise

the

temperature.

5) Once

proper

calibration

has

been

obtained,

the

call for heat

LED will

illuminate

within 14'F(7'C)

undershoot

and cycle

off

within

14"F(7'C)

of

overshoot.

6)

Tighten the calibration

screw

and the

l/2"

potentiometer

nut

and

paint

the head

of the

calibration

screw and the

area next to

the

screw with

a tamper

proof

shellack.

7)

Replace

the control

knob making

sure

it aligns

with

the 350'dial

indicaror

mark.