Page 13

CAUTION: Before making the gas pipe connection give seri-

ous consideration to providing the required clearance neces-

sary to remove the access panels on the unit (e.g., economizer

and filter access panels).

NOTE: In the absence of local codes, the installation must

conform with American National Standard--Z223.1--National

Fuel Gas Code, Latest Revision.

The available gas supply must agree with the required gas supply

marked on the unit nameplate. Minimum permissible gas supply

pressure for purpose of input adjustment must be at least 7.0 in.

w. c. (inches water column) for natural gas and 11 in. w. c. for LP gas.

PIPE DELIVERY SCHEDULE

NOTE: The following procedure and tables below apply to

Natural Gas only.

1. Obtain from the gas company the heating value and specific

gravity of the gas delivered.

2. Determine the exact length of pipe needed.

3. Read BTUH input nameplate on the furnace.

4. Use the multiplier opposite the specific gravity of the gas given

in Table 1 below and insert in the following formula:

CFH =

Furnace Input in BTUH

Gas Heat Content in BTU/Cu. Ft. X Multiplier

TABLE 1

This will give the factor for columns 2 through 6 in Table 2.

GAS PIPING INSTALLATION

7. Read horizontally to the left of this column for the required pipe

size diameter.

5. Using Table 2, select the pipe length nearest to yours.

TABLE 2

6. Follow this line vertically down to the exact CFH found in Step 4

above or the next highest value.

NATURAL GAS ONLY

TABLE OF CUBIC FEET PER HOUR OF GAS

FOR VARIOUS PIPE SIZES AND LENGTHS

PIPE

SIZE

(inch)

LENGTH OF PIPE (feet)

10 20 30 40 50 60 70

1/2 132 92 73 63 56 50 46

3/4 278 190 152 130 115 105 96

1 520 350 285 245 215 195 180

1-1/4 1050 730 590 520 440 400 370

THIS TABLE IS BASED ON PRESSURE DROP OF 0.3 INCH W.C. AND 0.6 SP.GR. GAS

NOTE: If this is an LPG application, consult your LPG supplier

for pipe sizes and deliveries.

GAS PRESSURE SETUP PRECAUTIONS

IMPORTANT: The furnace and its individual shut-off valve

must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures

exceeding 1/2 psig (3.48 kPa).

The furnace must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures less than

or equal to 1/2 psig (3.48 kPa).

GAS SUPPLY LINE PRESSURE

Before connecting the unit to the gas supply line, be sure to

determine the gas pressure in the line.

If the gas supply pressure is excessive (above 14 inches water

column or 1/2 psig), install a pressure regulator either at the supply

source or in the branch circuit serving the unit. Once the regulator

is installed, set it to provide a pressure of 7 inches water column with

the unit operating and no greater than 14 inches water column with

the unit not firing.

NOTE: Gas pressure in excess of 14 inches water column

(1/2 psig) may damage the regulator, while improper regulation

may result at pressures lower than 5.5 inches water column at

the unit inlet.

If the supply line pressure is below the minimum supply pressure

indicated on the unit nameplate, contact the gas supply company.

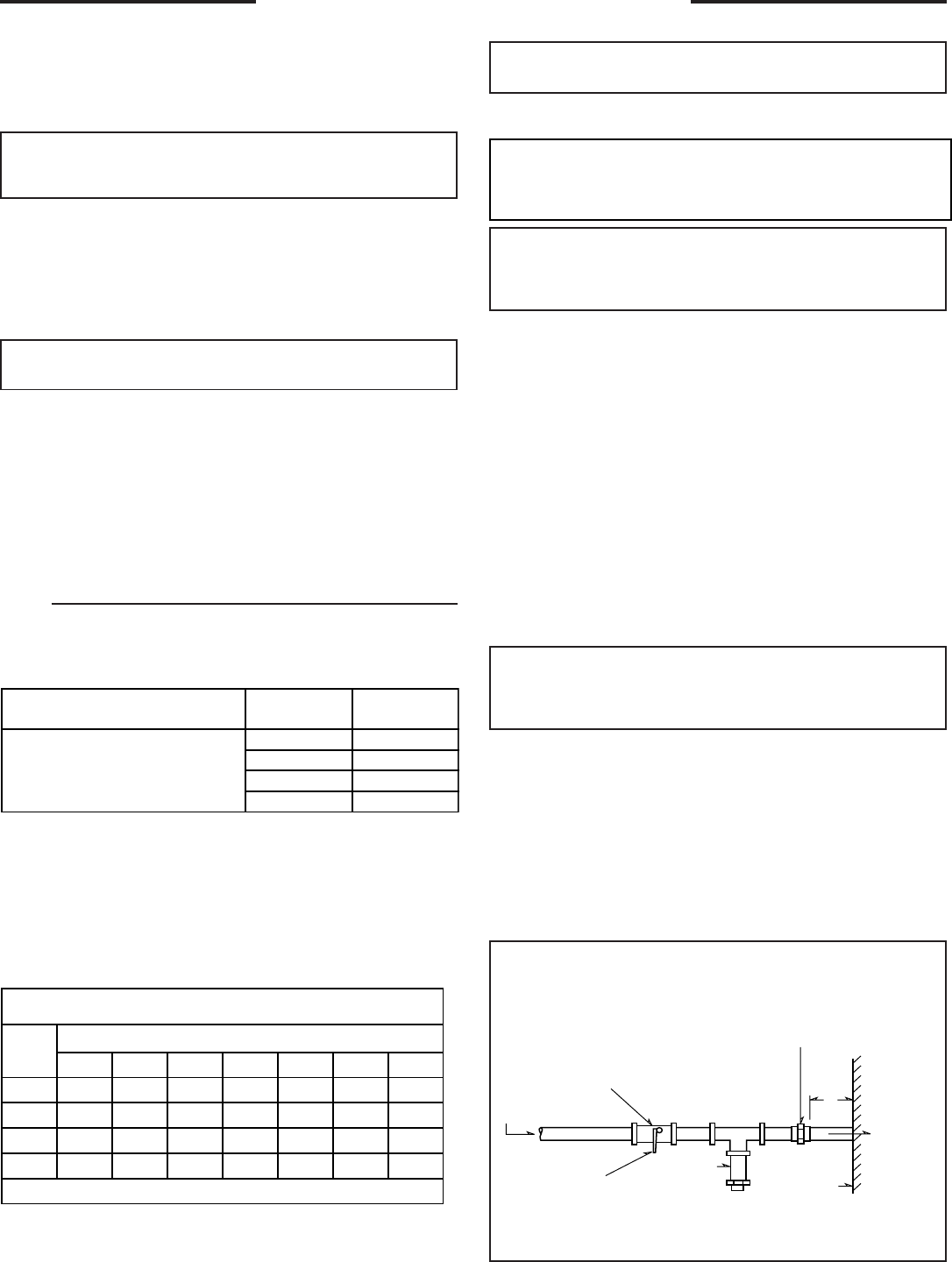

Follow these steps to complete the installation of the unit gas piping.

See Figure 14.

1. Install a tapped, Style A (1/8-inch NPT tap) shut-off gas cock at

the end of the gas supply line near the unit. Be sure the tapped

gas cock is downstream of the pressure regulator, if used.

SPECIFIC

GRAVITY

MULTIPIER

MULTIPIERS TO BE USED

WHEN THE SPECIFIC

GRAVITY OF THE GAS IS

OTHER THAN 0.60

.50 1.10

.55 1.04

.60 1.00

.65 .962

DEALER INSTALLED

GROUND UNION

1/8" N.P.T.PLUGGED

ACCESS FOR TEST

GAUGE CONNECTION

FROM

G

AS SUPPLY

DRIP LEG

FIELD SUPPLIED MAIN

GAS VALVE, MUST BE

INSTALLED BY DEALER

OUTSIDE UNIT.

UNIT

TO MAIN

CONTRO

L

VALVE

6"

MIN

SCHEMATIC DIAGRAM OF

GAS PIPING TO UNIT

▲WARNING: NEVER USE AN OPEN FLAME

TO TEST FOR GAS LEAKS: AN EXPLOSION COULD

OCCUR, CAUSING INJURY OR DEATH.

r