Hot Food Holding Cabinet Operation (continued)

Turning the unit OFF/ON: After the temperature has been set, the customer

can continuously turn the unit OFF and then back ON to the same temperature.

To turn the unit on or off press the ON/OFF button

.

Temperature Adjustment: Press the SET button

SET

and the UP Arrow

button at the same time. The display will flash the current temperature

setting or OFF (if the unit is turned off). Use the UP

or DOWN

Arrow buttons to adjust your desired temperature setting (temperature range

is 140

0

thru 180

0

F, and OFF) then press the SET button

SET

. The display

will go back to reading the cabinet temperature.

Important Alarm Events

Also, some R & A Series models can register alarm events on the control

display such as:

ELE LOS: Indicates that the power supply had been interrupted.

DOR OPN: Indicates that a door has been left open.

HI CAB: Indicates that the cabinet air temperature is too high.

LO CAB: Indicates that the cabinet air temperature is too low.

CLN FIL: Indicates that the condenser coil requires cleaning.

CAB SNR: Indicates cabinet sensor has failed.

COL SNR: Indicates coil sensor has failed.

DIS SNR: Indicates liquid line sensor has failed.

IV. Defrost Cycles:

All Upright Cabinets, defrost cycles will occur every 8 hours for all re-

frigerators and every 4 hours for all freezers. All TE & TU Series defrost

cycles occur every 2 1/2 hours. All TS Series defrost cycles occur every

3 hours and all Compacts, undercounter and prep table refrigerators, will

occur every 6 hours.

Units equipped with an LED temperature display will indicate when a defrost

cycle is in process.

V. GENERAL CARE:

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE CLEAN-

ING ANY PARTS OF THE UNIT.

All Traulsen equipment should be cleaned only with warm water, mild soap

and a soft cloth. Apply with a dampened cloth and wipe in the direction of

the metal grain.

Avoid the use of strong detergents and gritty, abrasive cleaners as they

may tend to mar and scratch the surface. Do not use cleansers containing

chlorine, this may promote metal corrosion.

Care should also be taken to avoid splashing the unit with water, containing

chlorinated cleansers, when mopping the floor around the unit.

For stubborn odor spills, use baking soda and water (mixed to a 1 TBSP

baking soda to 1 pint water ratio).

VI. ADJUSTING THE SHELVES:

Shelves Mounted On Pins

First select the desired location and remove the white plastic covers in the

interior back and sides by rotating them counter-clockwise. Remove the

shelf pins by rotating them counter-clockwise. Install the pins in the desired

location by rotating them clockwise. Make sure the pin is securely tightened

down. Do not over tighten. Slide the shelf into its new position, and replace

the white plastic covers into the holes vacated by the shelf pins.

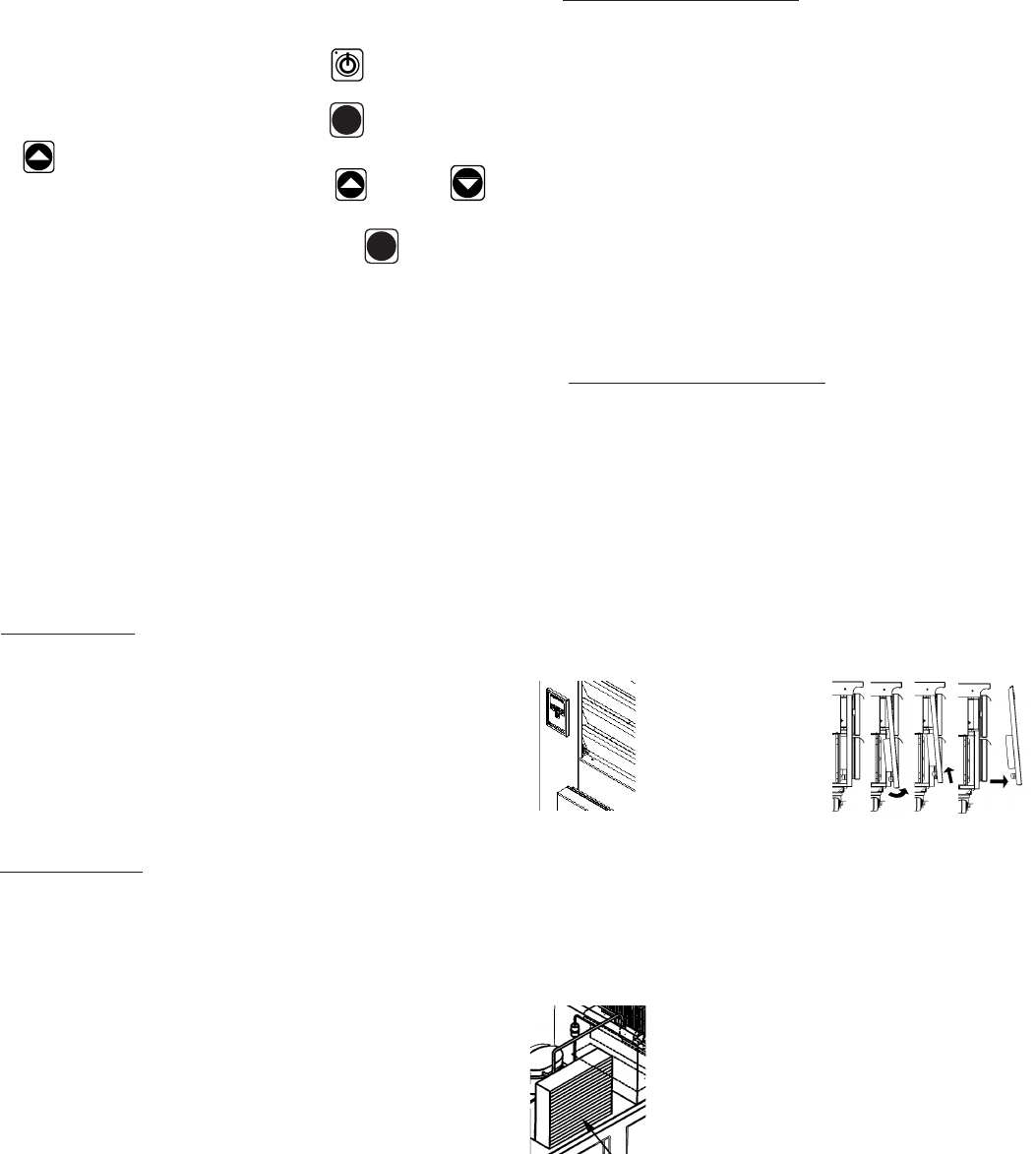

Shelves Mounted On Clips & Pilasters

Shelves and shelf clips are shipped with the unit. For each shelf, insert

four (4) shelf clips into the pilaster slots at the same height. The shelf

clips have a small projection on top which holds the shelf in position and

prevents it from slipping forward. After installing shelf clips on pilasters,

place shelves on clips.

VII. CLEANING THE CONDENSER:

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY BEFORE

CLEANING ANY PARTS OF THE UNIT.

This is the single most important thing you can do to promote long, efficient

equipment life. For All Upright Cabinets, remove the two bottom screws

securing the louver panel, then pivot this upwards allowing full access to the

front facing condenser. For all TE Series, TU Series & TS Series, place

hands under the louver panel and pull out and up to get louver panel off

bracket of the unit. Contact factory service support for all Compacts.

R & A Series/G Series TE/TU/TS Series

Louver Louver

Vacuum or brush any dirt, lint or dust from the finned condenser coil, around

the compressor and other cooling system parts as indicated. If significant

dirt is clogging the condenser fins, use compressed air to blow this clear.

When finished reverse the louver removal process as instructed above.

Condenser Coil

Screw

Location

-3-