3-27

Section 3 - Service and Repair

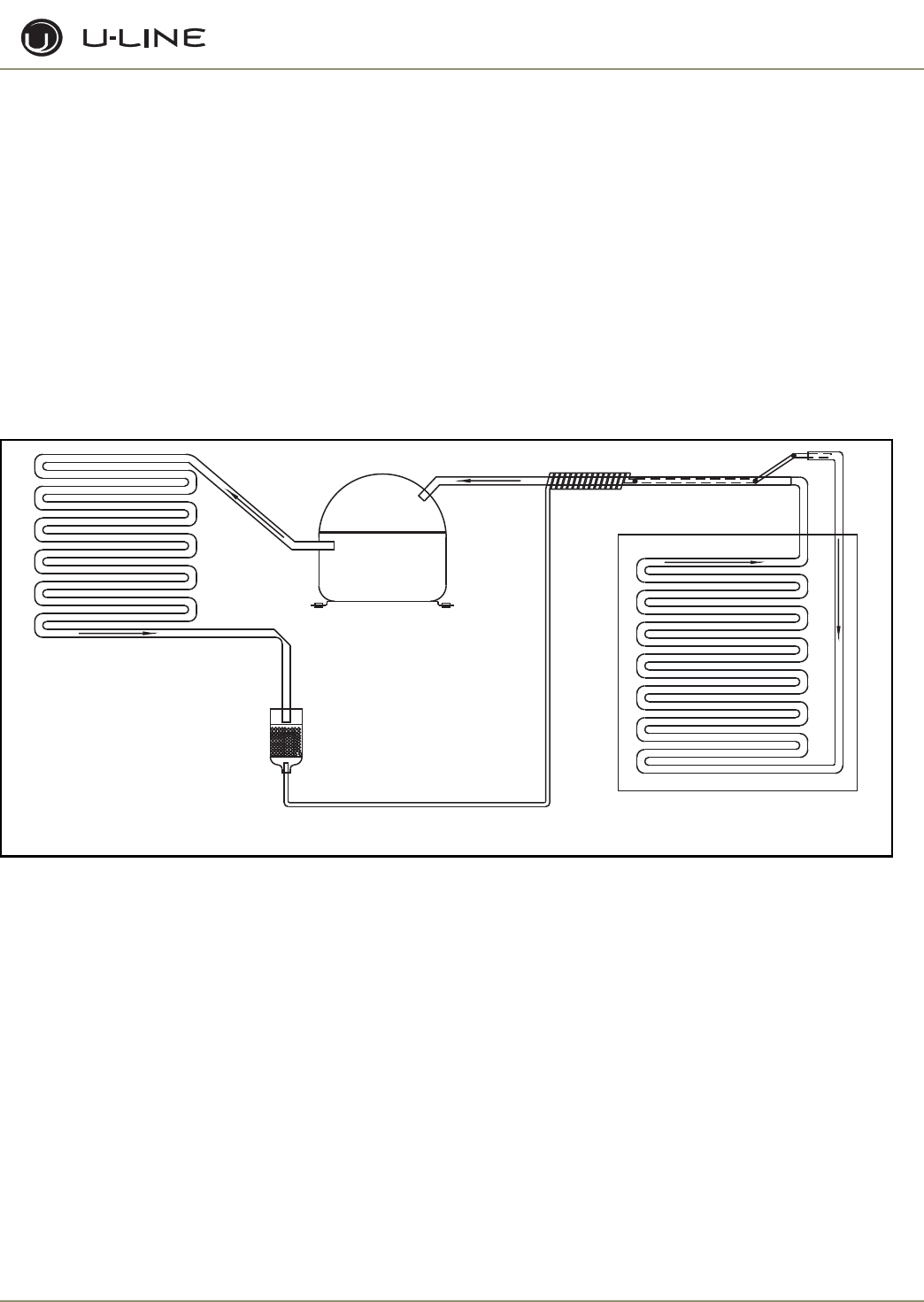

1175R/1115R

1175WC/1115WC

1175BEV/ADA24R

GENERAL

Refrigerant is pumped from the compressor to the condenser as a

high pressure, high temperature vapor.

As the refrigerant cools in the high pressure condenser, the vapor

condenses to liquid. During this phase change, a great amount of

heat is rejected with the help of the condenser fan.

The liquid then flows to the dryer where it is strained and filtered.

From the dryer, the refrigerant flows through the capillary tube

which meters the liquid refrigerant to the evaporator. The

pressure of the refrigerant is reduced to the evaporating or low

side pressure.

The reduction of pressure on the liquid refrigerant causes it to boil

or vaporize until it reaches saturation temperature. As the low

temperature refrigerant passes through the evaporator coil, it

continues to absorb a lot of heat, causing the boiling action to

continue until the refrigerant is completely vaporized. It is during

this phase that the most heat is absorbed (the cooling takes place)

in the refrigerator.

The refrigerant vapor leaving the evaporator travels through the

suction line to the compressor inlet. The compressor takes the

low pressure vapor and compresses it, increasing both pressure

and temperature. The hot high pressure gas is pumped out the

discharge line and into the condenser. The cycle continues

Figure 23. 1175R/1115R/1175WC//1115WC1175BEV/ADA24R Normal Vapor/Compression Cycle

These are some additional general notes and exceptions: • The unit is equipped with a four-minute compressor off cycle.

CAPILLARY TUBE

DRYER

CONDENSER

COMPRESSOR

EVAPORATOR

ULIN_0280_A