- 8 -

• Supply and return air flow from the evaporator unit shall be unobstructed

for at least 1 foot.

• There is a gravity drain line so that it can not be installed above the

evaporator unit. Otherwise a condensation pump must be used.

3. Air Sensor

• The air sensor can be located in the wine room or the return air area, but

not the supply air area.

4. Refrigeration Piping and Charging

NOTES: ALWAYS USE THE SUPERHEAT AND SUBCOOLING,

PRESSURE READINGS TO CHARGE REFRIGERANT PROPERLY, THE

LISTED CHARGES ARE FOR REFERENCE ONLY.

• The installation order starts from condensing unit (including the receiver),

liquid line filter-drier, moisture-liquid indicator (sight glass), liquid line,

evaporator unit (including liquid line solenoid valve and thermostatic

expansion valve or automatic expansion valve), suction line, and returning

to condensing unit.

• The subcooling at the condensing unit shall be around 10° F. The charge

may be complete when there are no more bubbles forming in the sight

glass.

• The evaporator’s constant pressure expansion valve is set around 38-

40°F at factory. This pressure setting gives a dew point to maintain the

humidity for storing wine.

• The superheat at the evaporator unit shall be around 9-18°F under low

and high load at 75°F ambient temperature.

• Low side pressure: 33 psig

• High side pressure: 130 -150 psig at 75 -90

°F ambient temperatures

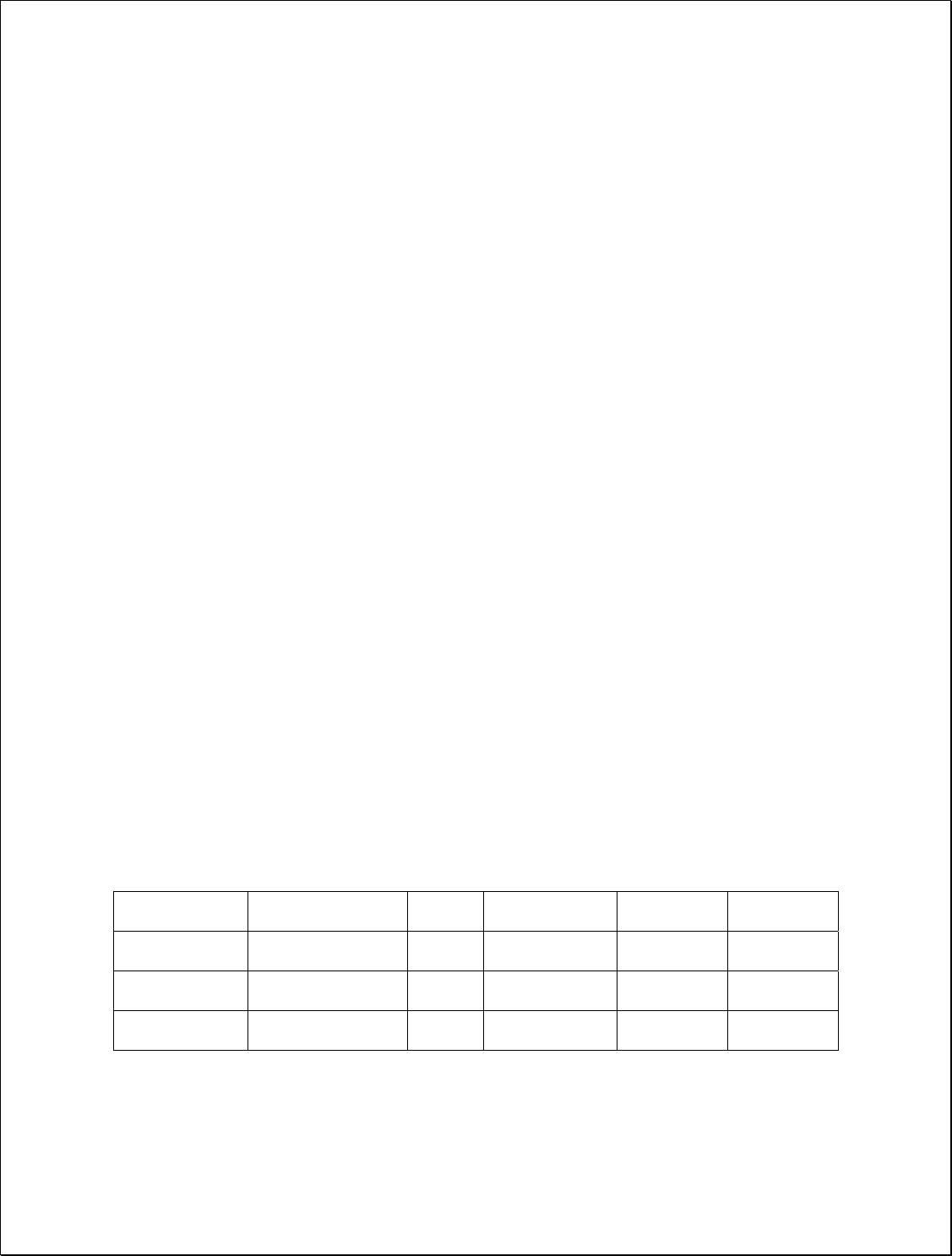

The line sizes and refrigerant charges are listed as follows.

MODEL

REFRIGERATION

LINES

LIQUID

LINE

SUCTION

LINE

DRAIN

LINE

CHARGE

VINO-

2500SSR

< 50 FT

1/4"

OD

3/8” OD 1/2” OD

R134a/

20 OZ

VINO-

4500SSR

< 50 FT

1/4"

OD

1/2” OD 1/2” OD

R134a/

26 OZ

VINO-

6500SSR

< 50 FT

1/4"

OD

5/8” OD 1/2” OD

R134a/

32 OZ