-

5 -

GAS CONNECTION

Gas supply connections and any pipe joint compound must be

resistant to the action of propane gases.

Codes require that a manual gas valve be installed in the gas supply line ahead of the appliance. Make sure the

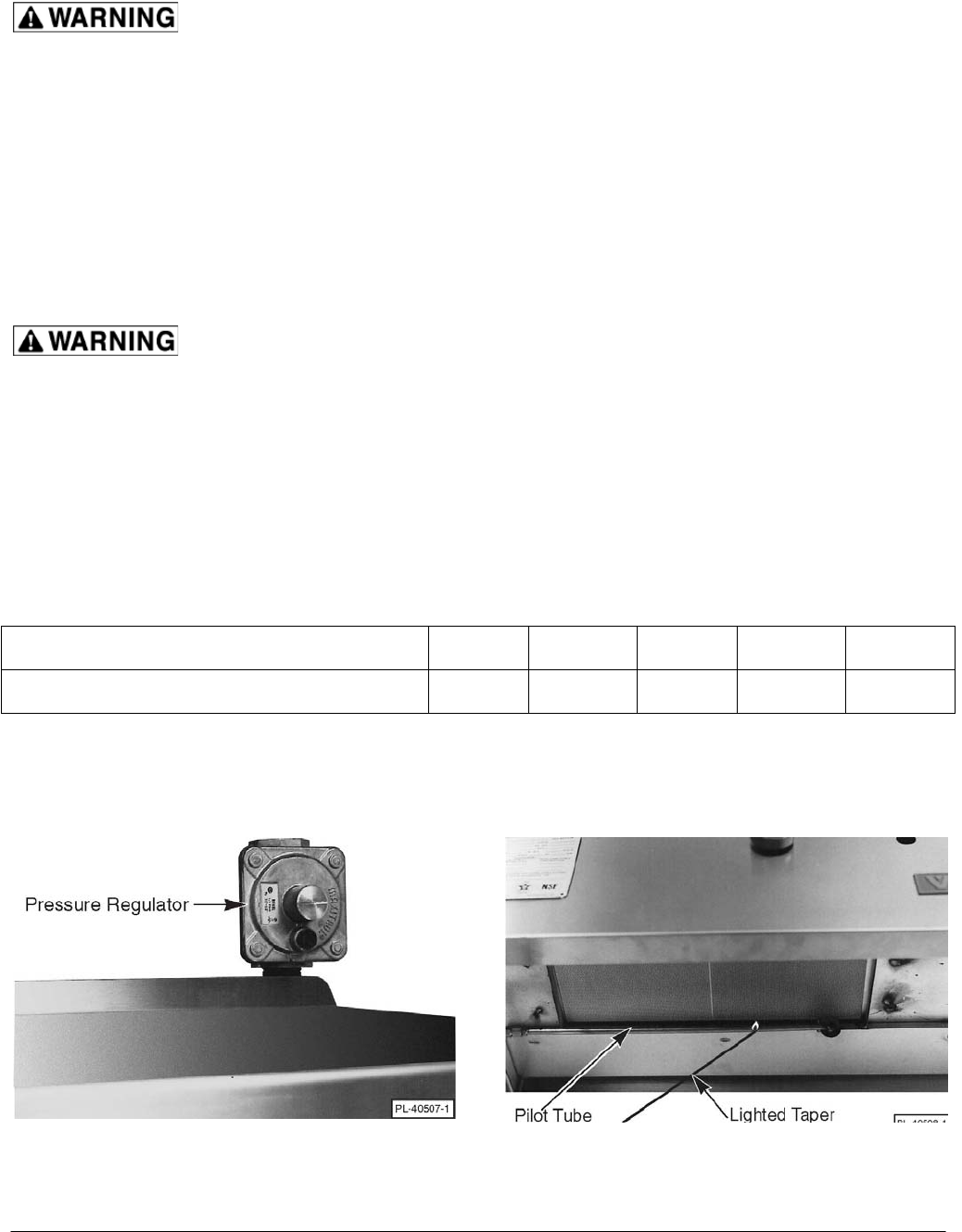

pipes are clean and free of obstructions, dirt, and piping compound. A pressure regulator is supplied loose with

the Cheese Melter for installation in the gas supply line. The Natural gas regulator requires a pressure of 5" Water

Column. The Propane gas regulator requires a pressure of 10" Water Column. The arrow on the rear of the

pressure regulator indicates the direction of gas flow. The regulator (Fig. 2) must be installed so the arrow points

down. If it is installed so the arrow is not pointing down, the pressure must be reset. Connect the Cheese Melter

to the gas supply with a

3

/4" iron pipe or larger. If a flexible connector is used, it must be

3

/4" I.D. A

1

/8" pressure

tap is located on the manifold for checking the gas pressure. Natural or Propane gas conversion and orifice

changes for various altitudes can be performed by Vulcan-authorized servicers.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

TESTING THE GAS SUPPLY PIPING

When test pressures exceed ½ psig (3.45 kPa) the Cheese Melter and its individual shut-off valve must be

disconnected from the gas supply piping system during any pressure testing of the system. When test pressures

are 1/2 psig (3.45 kPa) or less, the Cheese Melter must be isolated from the gas supply piping system by closing

its individual shut-off valve during any pressure testing of the system.

EXHAUST FAN

A mechanical exhaust hood must be installed above the appliance; the exhaust blower must have a capacity of

200 CFM per square foot of broiler area, check local code for specific requirements.

Model

ICM24

ICM36

ICM48

ICM60

ICM72

Minimum Exhaust Fan Rating

388 CFM

604 CFM

821 CFM

1038 CFM

1255 CFM

LIGHTING THE GAS PILOT TUBE(S)

Before lighting the Cheese Melter, make sure that all burners are turned off. Wait 5 minutes. Turn on the manual

gas valve and use a taper to light the gas pilot tube(s). A gas pilot tube is located below each burner (Fig. 3).

Fig. 2 Fig. 3