2. Open pressure relief valve until reservoir jacket

is completely vented. Allow valve to snap shut to

seal.

3. Remove pressure relief valve from kettle to vent

the jacket and facilitate draining. Retain for

reuse.

4. Remove draw-off valve or plug valve from kettle

(stationary models only).

5. Place container under kettle to catch fluid and

position it below the sight glass.

6. Remove sight glass using 36mm socket.

A. Stationary Models - Tilt kettle forward and

lay flat to completely drain.

B. Tilting Models - Turn crank handle clockwise

to tilt the kettle forward.

7. After draining is complete, place kettle in full

upright position.

A. Install sight glass and tighten it to seal the

internal O-ring to prevent leaks.

8. To Refill.

A. With kettle in full upright position.

B. If installed, open the manual valve on the fill

port for the reservoir jacket at back of kettle.

C. Remove pipe plug from valve/pipe elbow to

open the fill port.

D. Insert funnel into the fill port and slowly add

mixture of water and heat transfer fluid to the

reservoir jacket. Fill the jacket according to

the volumes listed in the table below. The

level in the sight glass should be 1/3 full.

RESERVOIR JACKET VOLUME

Model

Total Fluid

Volume

(GAL)

Water

(GAL)

Heat

Transfer

Fluid (GAL)

K20GL,

K20GLT

6.5 4.5 2.00

K40GL,

K40GLT

5.75 3.75 2.00

K60GL,

K60GLT

8.75 6.00 2.75

9. Close manual valve (if installed) to prevent leaks.

Hand tighten only.

10. Clean pipe plug threads and apply thread

sealant. Install pipe plug into valve/pipe elbow

opening to close the fill port. Tighten to prevent

leaks.

11. Install pressure relief valve to kettle.

12. Install draw-off valve or plug valve to kettle

(stationary models only).

13. Re-connect power.

14. Turn power switch on and verify low water light is

not lit.

A. If low water light is lit, see Possible Causes

for Low Water Light Lit in

TROUBLESHOOTING.

B. If low water light problem is still not resolved

see Possible Causes for Kettle Does Not

Heat in TROUBLESHOOTING.

15. Remove air from reservoir jacket as outlined

under VENTING.

16. Check kettle for proper operation and leaks

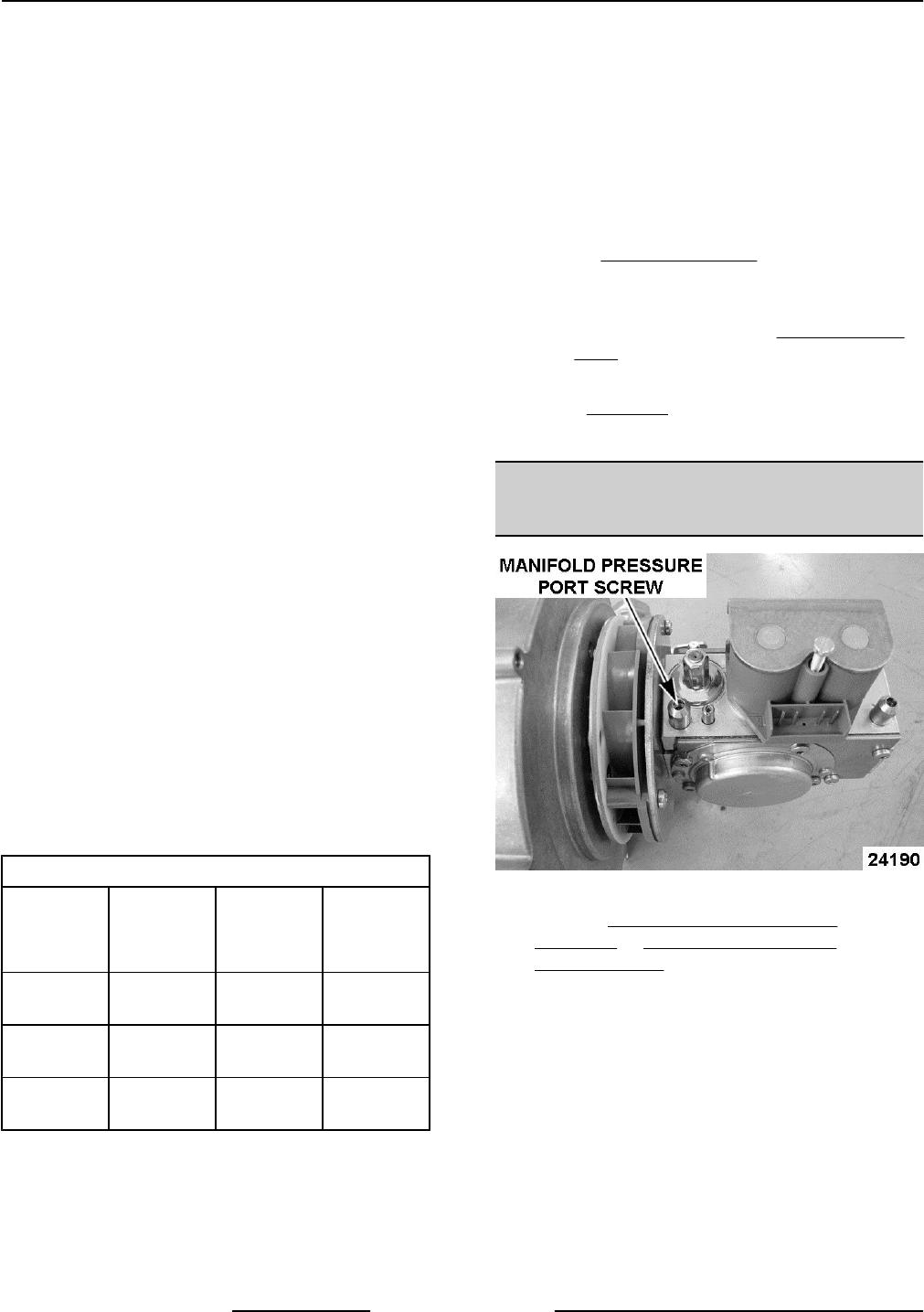

BLOWER INLET PRESSURE

CHECK

Fig. 39

1. Remove CORNER & REAR PANELS

(TILTING) or SIDE & REAR PANELS

(STATIONARY) to access blower & gas valve.

2. Remove electrical connector from gas valve.

3. Open manifold pressure port. Turn screw 1 to 2

turns CCW.

4. Attach U inclined manometer hose to manifold

pressure port.

5. Turn Kettle on.

6. Measure blower vacuum pressure.

A. Blower low speed (during trial for ignition, 7

sec) - Vacuum pressure reading should be

0.27" W.C. to 0.30" W.C.

K Series Gas Kettles 2/3 Jacketed Stationary and Tilting - SERVICE PROCEDURES AND ADJUSTMENTS

F45461 Rev. A (0713) Page 22 of 44