Printed On Recycled Paper

VULCAN-HART COMPANY, P.O. BOX 696, LOUISVILLE, KY 40201, TEL. 1-800-814-2028

502-778-2791 QUOTE & ORDER FAX: 1-800-444-0602

NOTE: In line with its policy to continually improve its products, Vulcan-Hart Company reserves the right to change materials and

specifications without notice.

F-32450 (8-04)

MODEL VCG10H

GAS COMBI OVEN

ACCESSORIES:

■■ Stainless steel stand with (legs) (casters).

■■ Pan slides for stand.

■■ Mobile landing table.

■■ Flexible water connection with (

3

/4" NSHT) - 2 required.

■■ Spray down hose with retaining hook, 118" long with

3

/4" hose bib fitting.

■■ Pan rack assembly.

■■ Wire racks. Qty._____.

■■ Chicken rack. Qty._____.

■■ Stacking kit (legs) (casters):

- Ten half on ten half.

- Ten half on ten full (refer to VCG10F spec no. F______).

■■ Additional pan rack support. Qty._____.

■■ 48" x

3

/4" flexible gas hose w/quick disconnect and restraining device.

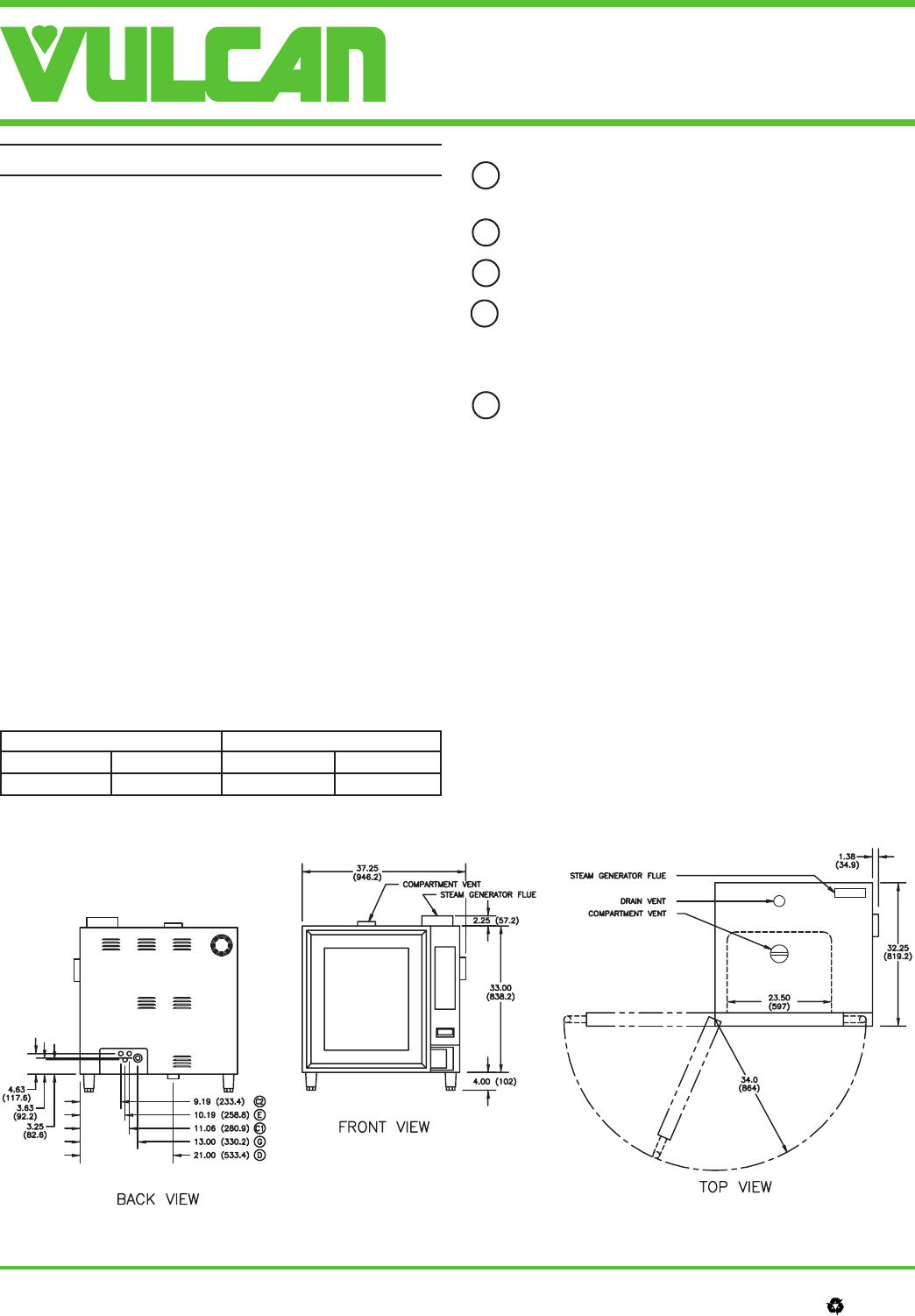

SERVICE CONNECTIONS:

E Electric connection for controls: 120/60/1, 300 watt maximum,

power supply with grounding wire required. (For other than 120 volt

supply, consult factory for location of this connection.)

C1 Cold water connection:

3

/4" NSHT for generator feed. Inlet water

pressure between 20 and 60 psi.

C2 Cold water connection:

3

/4" NSHT for condensate box. Inlet water

pressure between 20 and 60 psi.

D Drain: Condenser box, compartment and generator, 1

1

/2" NPT.

(Provide an open air gap type drain within 12" of condensate box and

for best results at a distance so that steam vapors will not enter the

steamer from underneath the control area.) Do not connect solidly

to any drain connection.

G Gas connection:

3

/4" NPT. Oven - 67,000 BTU/hr. Nat., 69,000

Propane, Boiler - 40,000 BTU/hr. Nat & Propane Gas.

NOTE:

• Dimensions which locate the above connections have a tolerance of

+ or -3" (+ or -75 mm).

• Installation of backflow preventers, vacuum breakers and other

specific code requirements is the responsibility of the owner and

installer. It is the responsibility of the owner and installer to comply with

local codes.

• Plastic drains are not recommended due to inherent limited tempera-

tures of the plastic. Boiler purge temperatures may exceed 180°F. The

installer may be required to provide means to reduce boiler purge

water temperature to be that of the condensate temperature of 140°F

or less.

• This appliance is manufactured for commercial installation only and is

not intended for home use.

IMPORTANT:

1. A pressure regulator sized for this unit is included. Natural gas 8.0"

W.C. Propane 10.5" W.C.

2. Gas line connecting to unit must be

3

/4" or larger. If flexible connectors

are used, the inside diameter must be at least the same as the

3

/4"

iron pipe and rated for the correct gas input.

WATER QUALITY STATEMENT:

The fact that a water supply is potable is no guarantee that it is suitable for

steam generation. Your water supply must be within these general

guidelines:

SUPPLY PRESSURE 20 - 60 psig

HARDNESS* less than 3 grains

SILICA less than 13 ppm

TOTAL CHLORINE less than 4.0 ppm

pH RANGE 7-8

UN-DISSOLVED SOLIDS less than 5 microns

* 17.1 ppm = 1 grain of hardness

Other factors affecting steam generation are iron content, amount of

chloridation and dissolved gases. Water supplies vary from state to state

and from locations within a state. Therefore it is necessary that the local

water treatment specialist be consulted before the installation of any

steam generating equipment.

PAN CAPACITY

STEAM TABLE PANS BAKE PANS

12" x 20" x 2

1

/2" 12" x 20" x 4" 18" x 13" 18" x 26"

10 6 10 N/A

CLEARANCES: 4" right 6" rear