the broil element. Set the oven

seledor and oven temperature control

knobs to “BROIL:‘The too element should

glow red and Indicate light should

beon.

kwlre electrical connection

11.

:

nd

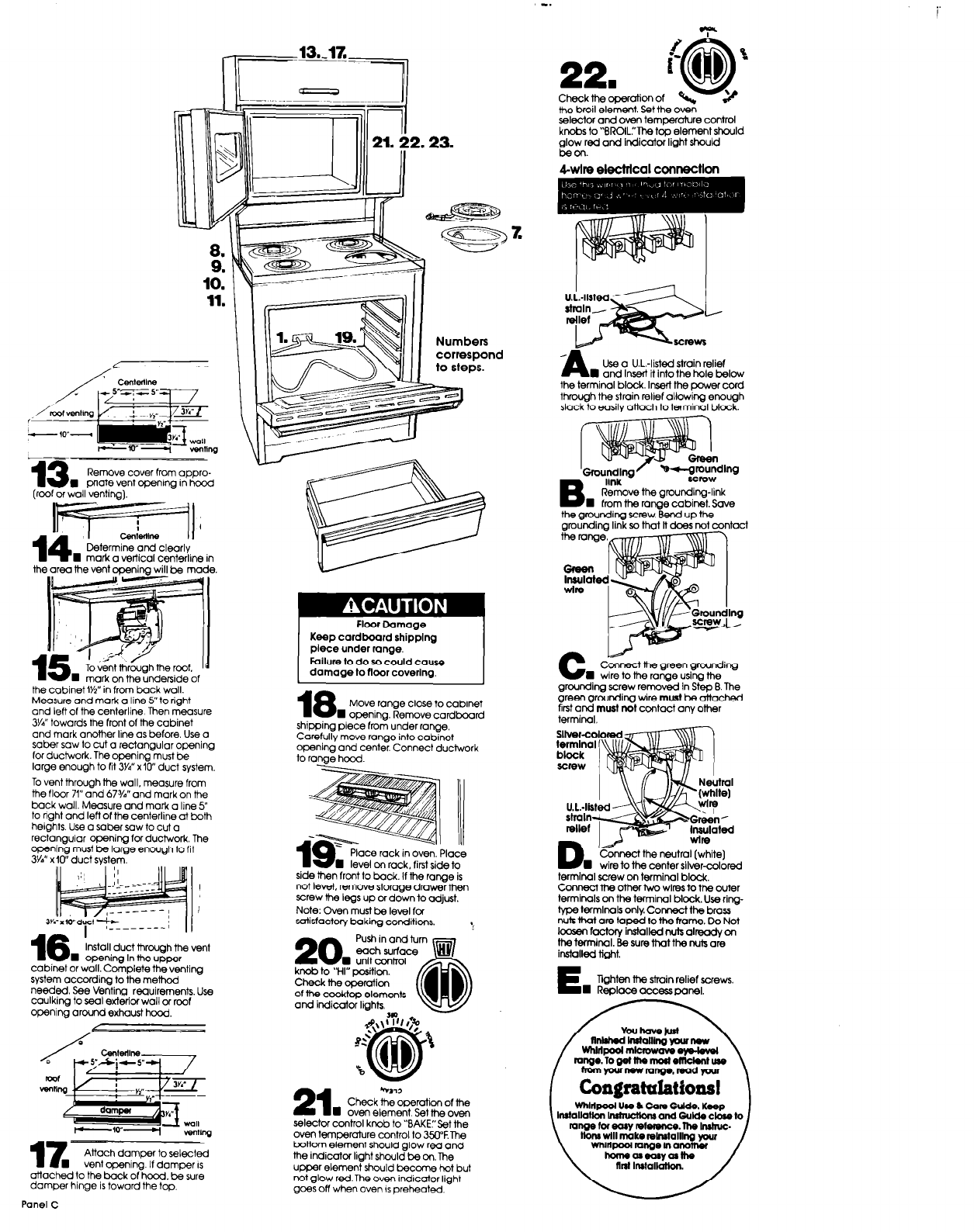

Use a U.L.-listed strain relief

n

and Insert it into the hole below

the terminal block. Insert the paver cord

through the strain relief allowing enough

slack to easily attach to terminal block.

t---.-

13

Remove cover from appro-

n

prtate vent opening in hcod

(roof of wall ventinat.

- -’

Gs---7-?I

‘1’

14.

T CenLne II I

.

Determine and clearly

mark a vertical centerline in

the grounding screw.Bend

up the

grounding

link so that It does not contact

the area the vent opening will be made.

the range.

Floor Damage

Keep cardboard shipplng

piece under range.

FoIlurn to do so could cause

damage to floor coverlng.

C

LA--

Connect the green grcunding

W wire to the range using the

grounding screw removed In Step B. The

green grounding wire

must

be attached

;;tmi~lmust not contact any other

TOY&~ thr&gh the roof. jd

mark on the underside of

the cabinet IYz” in from back wall.

Measure and mark a line 5’to right

and left of the centerline Then measure

W” towards the front of the cabinet

and mark onother line as before. Use a

saber saw to cut a rectangular opening

for ductwork. The opening must be

large

enough

to fit 3Y4” x lo” duct system.

To vent through the wall, measure from

the floor 71” and 67%” and mark on the

back wall. Measure and mark a line 5”

to right and left of the centerline at both

heights. Use a saber saw to cut a

rectangular opening for ductwork The

opening must be large enough to fit

3Y4” x IO” duct system.

Move range close to cabinet

n

ODenina. Remove cardboard

shipping piece from under ranae

Careful& move range into cab:net

openina and center. Connect ductwork

to range hood

I

&nect the neutral (white]

wire to the center silvercolored

ace rack in oven.

Place

Vet on rack, first side to

side then front to back. If the ranae is

terminal screw on terminal block.

Connect the other two wires to the outer

terminals on the terminal block. Use rirg-

Npe terminals only Connect the brass

nuts that am taped to the tram-e. Do Not

kznsen factory installed nuts already on

the terminal. Be sure that the nuts are

installed tight.

E

Tighten the strain relief screws.

n

Replace access panel.

not level, remove storage drawerthen

screw the legs up or down to adjust.

Note: Oven must be level for

satisfactory baking conditions,

3v&y-&i+s

I

I__- ---__/

16

W

Install duct through the vent

opening In the upper

cabinet or wall. Complete the venting

system according to the method

needed See Venting requirements. Use

caulking to seal exterior wall or roof

opening around exhaust hood.

20

Push in and turn

n

knob to “HI” posttion.

Check the operation

of the ccoktop elements

and indicator lights

21

*1.72

n

Check the operation of the

oven element. Set the oven

selector control knob to “BAKE:‘Set the

oven temperature control to XW.The

bottom element should glow red and

the indicator light should be on The

upper element should become hot but

not glow redThe oven indicator light

goes off when oven IS preheated

WhMpoolmlcmwaveeys-kvel

mnQ0.10getthernaslonktentuae

homyourmwrange.roodpur

range far easy mfemnce. me lmhuc.

tloru will make mlrutalllng your

WMtpool range In another

llameasoasyaafhe

nd

Installation.

17---=-

Attach damper to selected

n

vent opening. If damper IS

attached to the back of hood, be sure

damper hinge is toward the top,

Panel C