2

INSTALLATION

If the boiler manufacturer recommends a control location, then

follow such recommendations. Otherwise, locate the control as

close to the top of the boiler as possible, but not in the same

section of the boiler that has fittings for domestic hot water.

Never locate the control near a return pipe to the boiler.

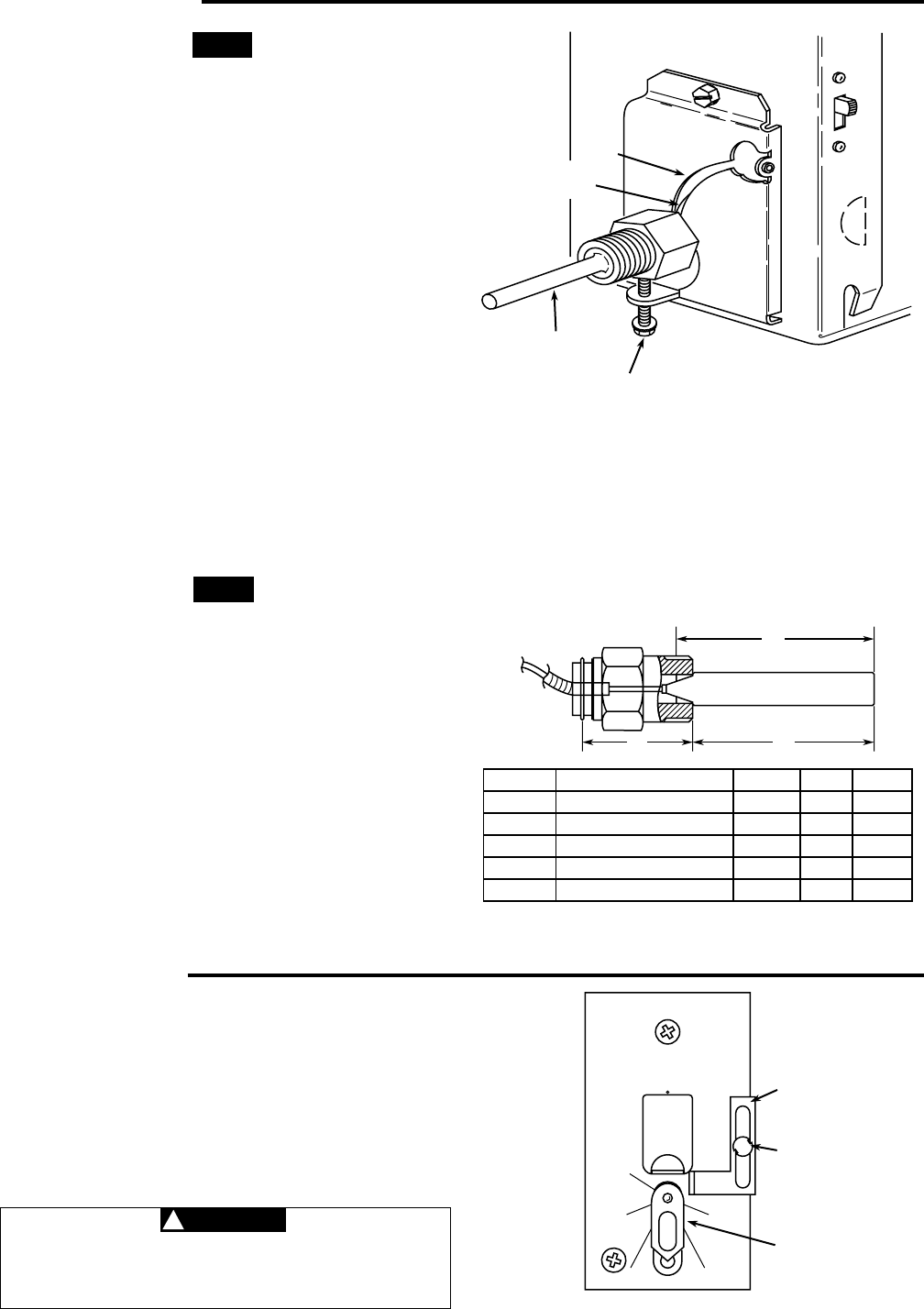

PREPARING TO MOUNT CONTROL

This control can be mounted vertically or horizontally.

1. Loosen the set-screw holding the well in place (see fig. 1).

2. Push down and out on the well and carefully slide the

capillary tube in slot.

3. Place the well in new notch and tighten the set-screw to

secure the well in the new position.

MOUNTING THE CONTROL

1. Disconnect electrical power to the boiler.

2. Completely drain the boiler.

3. If a well tapping is not provided, prepare one near the top of

the boiler.

4. Sparingly apply pipe joint compound to the well threads and

install well.

Use hex on well for tightening the well. Do not attempt to tighten

by using the case as a handle.

5. Refill the boiler and check for water leaks.

6. Insert the bulb element into the well until it bottoms.

7. Locate and secure the coil of excess tubing so that it cannot

touch electrical components.

8. Fit the back of the case into the well and tighten using the set-

screw on the back panel.

NOTE

NOTE

Figure 1

Slot

Well

Set-screw

Capillary

Tube

AB

C

1

⁄

2

” Std. Shank

1

⁄

2

” Std. Ext. Shank

3

⁄

4

” Std. Shank

3

⁄

4

” Std. Ext. Shank

3

⁄

4

” Extra Ext. Shank

1

13

⁄

16

”

3

5

⁄

16

”

1

13

⁄

16

”

3

5

⁄

16

”

4

13

⁄

16

”

3”

3”

3”

3”

3”

3

5

⁄

16

”

3

5

⁄

16

”

3

5

⁄

16

”

3

5

⁄

16

”

3

5

⁄

16

”

89-0211

89-0212

89-0213

89-0214

89-0215

Conductive Grease No. 145-0163

Well No. Description A B C

Figure 2

MOUNTING TO EXISTING WELL

(For use with well adaptor, which may be ordered separately.)

For best control performance, a well comparable to that shown

in fig. 2 is recommended. However, by using a heat conductive

grease, these controls will give satisfactory performance when

used with large-diameter existing wells. If desired, both the

conductive grease and replacement wells may be ordered

separately (see fig. 2).

DIAL SETTING

When replacing an existing control, adjust the setting of the high

limit to correspond with that of the old control.

Set the pointer to the temperature at which the contacts of the

high limit are to open (see fig. 3)

Models with a preset dial stop are to be adjusted by authorized

service personnel only.

To reset the dial stop, loosen the stop adjust screw and reposi-

tion the stop to the desired setting.

Retighten the stop adjust screw.

DO NOT set the stop higher than the original

manufacturer’s recommended setting. Personal injury

and/or property damage may result.

WARNING

!

140

160 220

200180

Stop

Stop

Adjust

Screw

Pointer

Figure 3