10

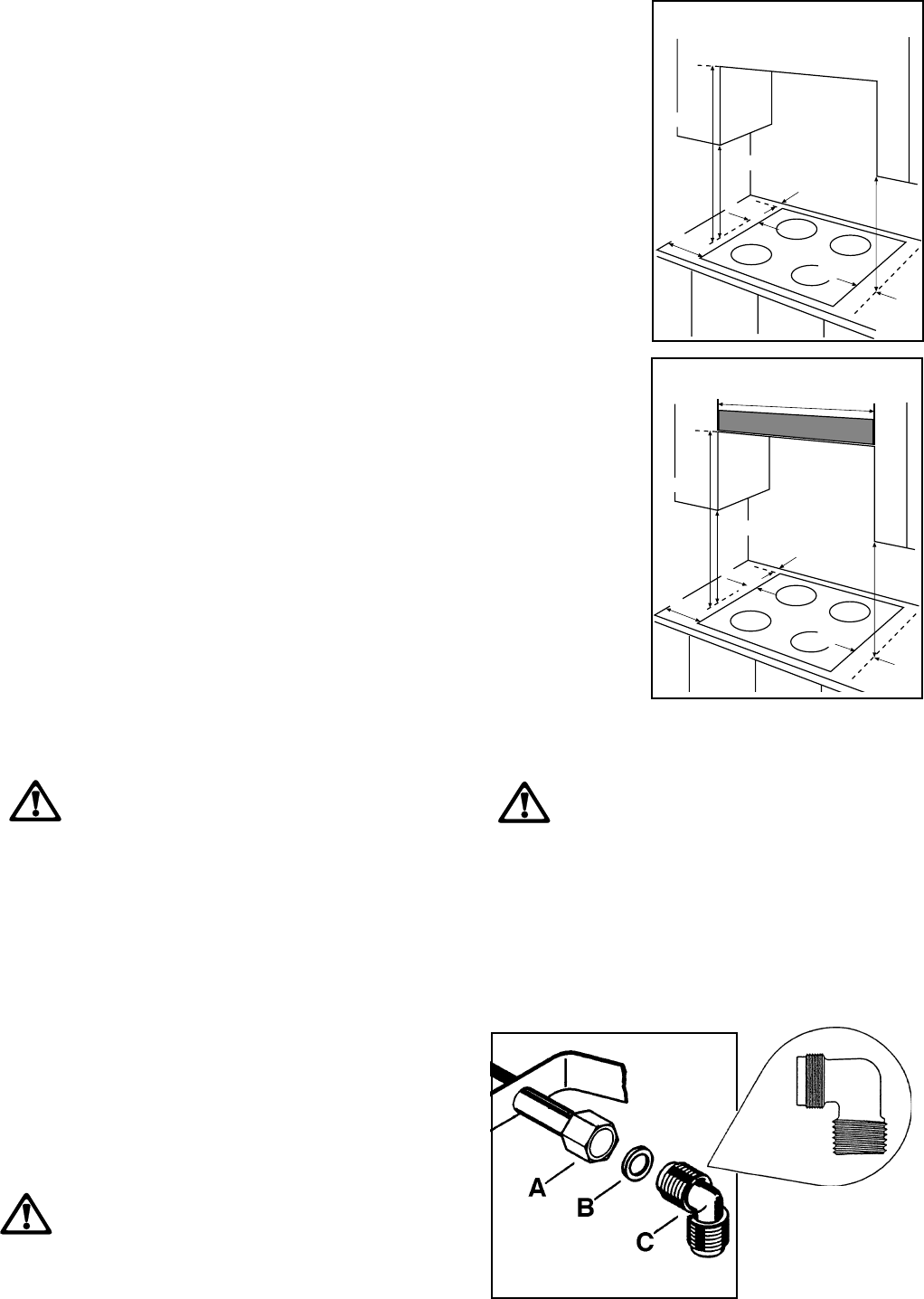

A) End of shaft with nut

B) Washer

C) Elbow

FO 0814

FO 0264

FITTING THE GAS HOB

WITHOUT A COOKER HOOD ABOVE

FITTING THE GAS HOB

WITH A COOKER HOOD ABOVE

700 mm

400 mm

100 mm

400 mm

50 mm

55 mm

50 mm

650 mm

400 mm

400 mm

100 mm

50 mm

50 mm

55 mm

600 mm

FO 0812

FO 0813

Important safety requirements

This hob must be installed in accordance with the Gas Safety (Installation and

Use) Regulations (Current Edition) and the IEE Wiring Regulations (Current

Edition).

Detailed recommendations are contained in the following British Standards Codes

Of Practice: B.S. 6172/ B.S. 5440, Part 2 and B.S. 6891 Current Editions.

The hob should not be installed in a bed sitting room with a volume of less than

20 m

3

. If it is installed in a room of volume less than 5 m

3

an air vent of effective

area of 110 cm

2

is required. If it is installed in a room of volume between 5 m

3

and

10 m

3

an air vent of effective area of 50 cm

2

is required, while if the volume

exceeds 11 m

3

no air vent is required.

However, if the room has a door which opens directly to the outside no air vent is

required even if the volume is between 5 m

3

and 11 m

3

.

If there are other fuel burning appliances in the same room, B.S. 5440 Part 2

Current Edition, should be consulted to determine the requisite air vent

requirements.

Location

The hob may be located in a kitchen, a kitchen/diner or bed sitting room, but not

in a bathroom, shower room or garage.

Before making the cut out in the worktop ensure that the edges of the hob that

are to be near either a side or rear wall have a minimum distance of 55 mm.

between the edge of the hob and the wall.

The minimum distance combustible material can be fitted above the hob is 400

mm. If it is fitted below 400 mm. a space of 50 mm. must be allowed from the

edges of the hob.

The minimum distance combustible material can be fitted directly above the hob

is 700 mm. A minimum distance of 100 mm. must be left between the side edges

of the hob and any adjacent cabinets or walls.

Installation

IMPORTANT

This hob must be installed by qualified

personnel to the relevant British Standards.

Any gas installation must be carried out by a

registered CORGI installer.

The manufacturer will not accept liability, should

the above instructions or any of the other safety

instructions incorporated in this book be

ignored.

Gas Connection

Connection to the gas supply should be with either rigid

or semi-rigid pipe, i.e. steel or copper.

The connection should be suitable for connecting to RC

1/2 (1/2 BSP male thread).

When the final connection has been made, it is essential

that a thorough leak test is carried out on the hob and

installation. Ensure that the main connection pipe does

not exert any strain on the hob.

It is important to install the elbow correctly, with

the shoulder on the end of the thread, fitted to the

hob connecting pipe.

Failure to ensure the correct assembly will cause

leakage of gas.

WHEN THE HOB IS FIRST INSTALLED

Once the hob has been installed, it is important

to remove any protective materials, which were

put on in the factory.

On the end of the shaft, which includes the GJ 1/2"

threaded elbow, adjustment is fixed so that the washer

is fitted between the components as shown in the

diagram. Screw the parts together without using excessive

force.