21

AIR FLOW BALANCING (CONT'D)

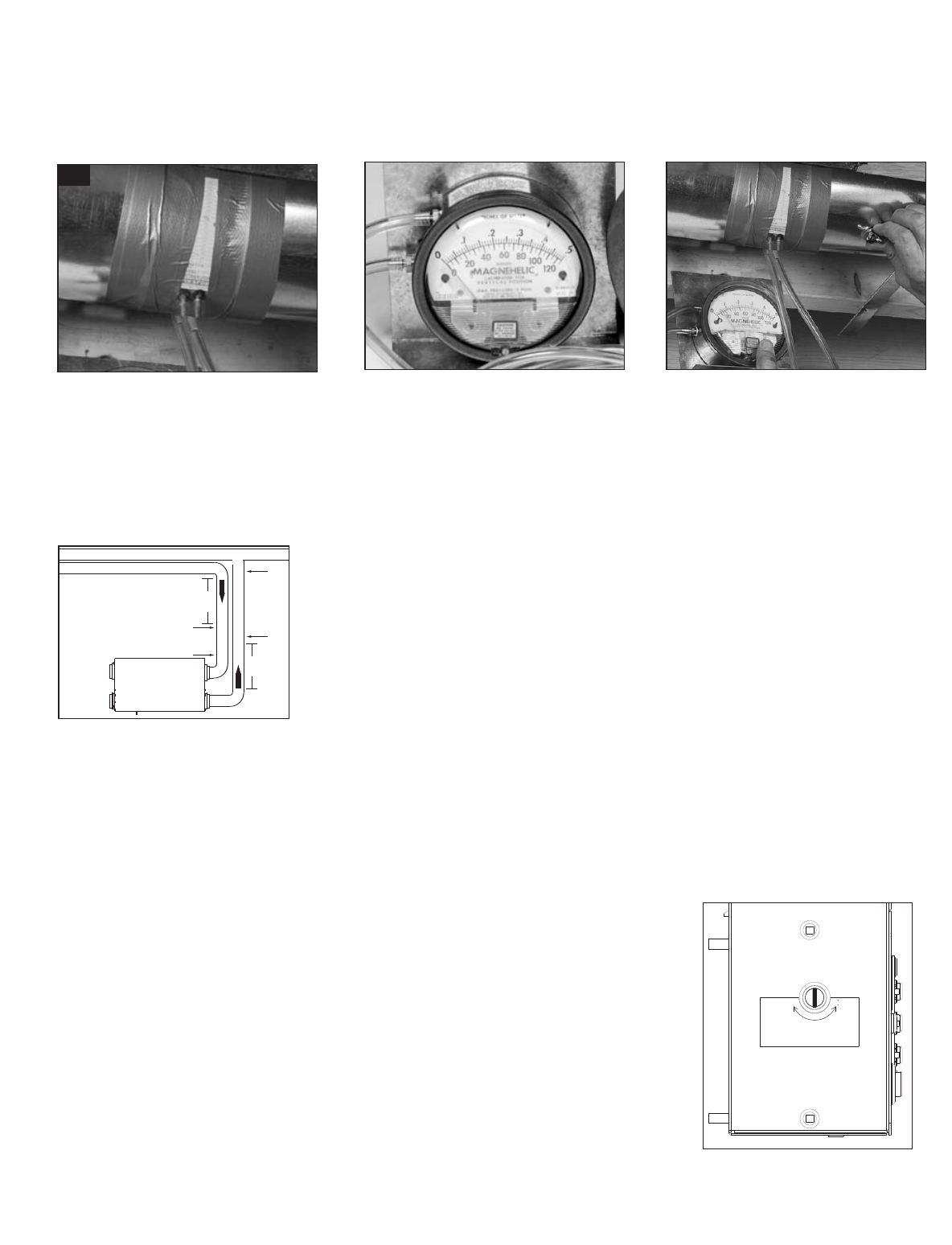

1 For this flow measuring station, cut

the duct and place the flow

measuring station between each

station. Make sure that the flow

measuring station’s air direction

arrow points in the direction of the

airflow. Secure the flow measuring

station with duct tape.

2 Before taking the reading, make sure

that the magnehelic gauge is level

and at 0. Refer to the flow

measuring station’s chart to

determine your unit’s airflow velocity.

3 Adjust the “Supply Air Out” damper

until you reach the desired velocity.

Follow the previous steps to adjust

the “Exhaust Air Out” damper, if

needed.

B

Measure

here

Measure

here

18”

(457 mm)

18”

(457 mm)

• To avoid airflow

turbulence and incorrect

readings, the airflow

velocity should be

measured on steel

ducting a minimum of

18” (457 mm) from the

unit or elbow and before

any transition.

ELECTRONIC BALANCING MOTORS [HRV 150D & 200D only] -

Motors will be factory set at their full potential depending on speed selected.

When unit is installed you will need to balance the motors for proper operation.

Insert screwdriver and turn clockwise to slow down the motor, you will notice the motor changing speeds

while performing this operation. Set to desired cfm.

Fan

+-

Use slot screwdriver to

adjust speed/airflow

AIRFLOW STATION (GRID) METHOD

ADJUSTING AIRFLOWS