10

V. Gas Piping

IMPORTANT NOTE: This furnace is factory set to oper-

ate on natural gas at the altitudes shown on the rating

plate. If operation at higher altitudes and/or propane gas

operation is required, obtain and install the proper con-

version kit(s) before operating this furnace. Failure to

do so may result in unsatisfactory operation and/or equip-

ment damage. (High altitude kits are for U.S. installa-

tions only.)

The rating plate is stamped with the model number, type

of gas and gas input rating. Make sure the furnace is

equipped to operate on the type of gas available.

INLET GAS PRESSURE

Natural Min. 5.0" W.C., Max. 10.0" W.C.

Propane Min. 11.0" W.C., Max. 14.0" W.C.

Inlet Gas Pressure Must Not Exceed the Maximum Value Shown

in Table 3.

Table 3

The minimum supply pressure should not vary from that

shown in the table above because this could prevent

the furnace from having dependable ignition. In addi-

tion, gas input to the burners must not exceed the rated

input shown on the rating plate. Overfiring of the fur-

nace could result in premature heat exchanger failure.

High Altitude Derate (US. Installations Only -

Canadian Installations to 4500 Feet Only)

When this furnace is installed at altitudes above 2000

feet, the furnace input must be derated 4% for each 1000

feet above sea level because the density of the air is

reduced.

In some areas the gas supplier will derate the heating

value of the gas at a rate of 4% for each 1000 feet above

sea level. If this is not done, smaller orifices will be re-

quired at altitudes above 3500 feet (non-derated natu-

ral gas) or 4500 feet (non-derated propane gas).

A different pressure switch will be required at altitudes

more than 4000 feet above sea level. This is required

regardless of the heat content of the fuel used.

High altitude kits can be purchased depending on the

altitude and usage of propane or natural gas. Refer to

the high altitude instruction manual included with this

furnace to determine which high altitude components to

use.

Adjustment of the manifold pressure to a lower pres-

sure reading than what is specified on the furnace name-

plate is not a proper derate procedure. With a lower den-

sity of air and a lower manifold pressure at the burner

orifice, the orifice will not aspirate the proper amount of

air into the burner. This can cause incomplete combus-

tion of the gas, flashback, and possible yellow tipping.

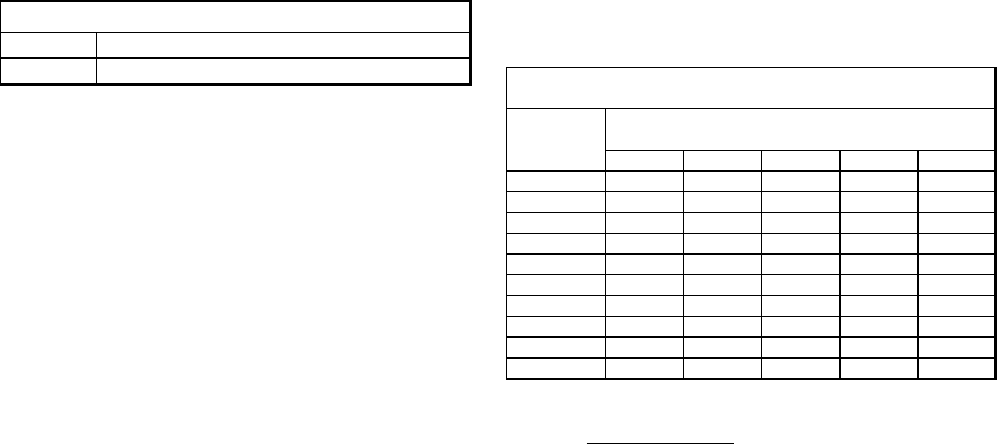

Gas Piping

IMPORTANT NOTE: To avoid possible unsatisfactory

operation or equipment damage due to under firing of

equipment, do not undersize the natural gas/propane

piping from the meter/tank to the furnace. When sizing

a trunk line as shown in Table 4, include all appliances

on that line that could be operated simultaneously.

The rating plate is stamped with the model number, type

of gas and gas input rating. Make sure the furnace is

equipped to operate on the type of gas available.

The gas line installation must comply with local codes,

or in the absence of local codes, with the latest edition

of the National Fuel Gas Code (ANSI Z223.1).

Connecting The Gas Piping - Natural Gas

Natural Gas Capacity of Pipe

in Cubic Feet of Gas Per Hour (CFH)

Length of

Nominal Black Pipe Size (inches)

Pipe in Feet 1/2 3/4 1 1 1/4 1 1/2

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 980

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

Pressure = .50 PSIG or less and Pressure Drop of 0.3" W.C. (Based

on 0.60 Specific Gravity Gas)

Btuh Furnace Input

Calorific Value of Gas

CFH=

Table 4

Refer to Figure 3 for the general layout at the furnace.

The following rules apply:

1. Use black iron or steel pipe and fittings for the build-

ing piping.

2. Use pipe joint compound on male threads only. Pipe

joint compound must be resistant to the action of

the fuel used.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it

can enter the gas valve. The drip leg must be a mini-

mum of three inches long.

5. Use two pipe wrenches when making connection to

the gas valve to keep it from turning.

6. Install a manual shut-off valve in a convenient loca-

tion (within six feet of unit) between the meter and

the unit.

7. Tighten all joints securely.