WARNING

TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS,

OBSERVE THE

FOLLOWING:

A. Installation Work and Electrical

Wiring Must Be Done By Qualifi ed

Person(s) In Accordance With All

Applicable Codes And Standards,

Including Fire-Rated Construction.

B. Suffi cient air is needed for proper

combustion and exhausting of

gases through the fl ue (chimney) of

fuel burning equipment to prevent

back drafting. Follow the heating

equipment manufacturer’s guideline

and safety standards such as those

published by the National Fire

Protection Association (NFPA), and

the American Society for Heating,

Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local

code authorities.

C. When cutting or drilling into wall or

ceiling, do not damage electrical

wiring and other hidden utilities.

D. When used as exhaust fans,

ducted fans must always be vented

to the outdoors.

E. If this unit is to be installed over a

tub or shower, it must be marked as

appropriate for the application and be

connected to a GFCI (Ground Fault

Circuit Interrupter) - protected branch

circuit.

White

Brown

Factory Wiring for

IP Protected Motors

White

Black

Neutral

Ground

115 V

Black

White

Brown

Black

Factory Wiring

Field Wiring

Field Wiring

Green/Yellow

Green/Yellow

anchors are recommended. The rubber

grommets provide vibration isolation.

The brackets should be attached to the

fan fi rst. Then install the wood screws at

the keyhole locations and install the fan.

The fan may also be mounted on a foam

rubber pad on a fl at surface, such as an

attic fl oor.

COLD CLIMATE PRECAUTIONS

If installed in an unheated space, in

cold climates, there is a possibility

of condensation forming in the fan

housing or ducting components. A

backdraft damper installed at each

grille is very effective in reducing the

potential for condensation when the fan

is cycled on and off. Insulated ducting

must be used where exposed to cold

attic or crawl space temperatures, to

avoid condensation in the ducting.

Condensation can also be avoided by

continuous operation of the fan.

DUCT CONNECTIONS

Ducting may be fl exible or rigid,

depending on local codes. If permitted

by code, insulated fl exible ducting is

recommended for at least several feet on

each duct connection, to limit fan noise at

the outlet grilles. Ducting should conform

to NFPA 90A and meet the requirements

of Underwriters Laboratory as a Class O

or Class 1 duct to specifi cation UL 181,

Standard for Factory-Made Air Ducts and

Duct Connectors. Metal ducting must

be sealed on both the end joints and

longitudinal seams to avoid duct leakage

and assure proper airfl ows at the grilles.

MAINTENANCE

Monthly:

Inspect and clean the exhaust grilles and

fi lters, if so equipped.

Annually:

To ensure the maximum effi ciency of

the fan unit, is recommended to clean

the inside of the fan box as well as the

blower wheel.

CAUTION:

Automatically operated device—to

reduce risk of injury disconnect from the

power supply before servicing.

DISASSEMBLY

Turn off all power to the unit. The blower

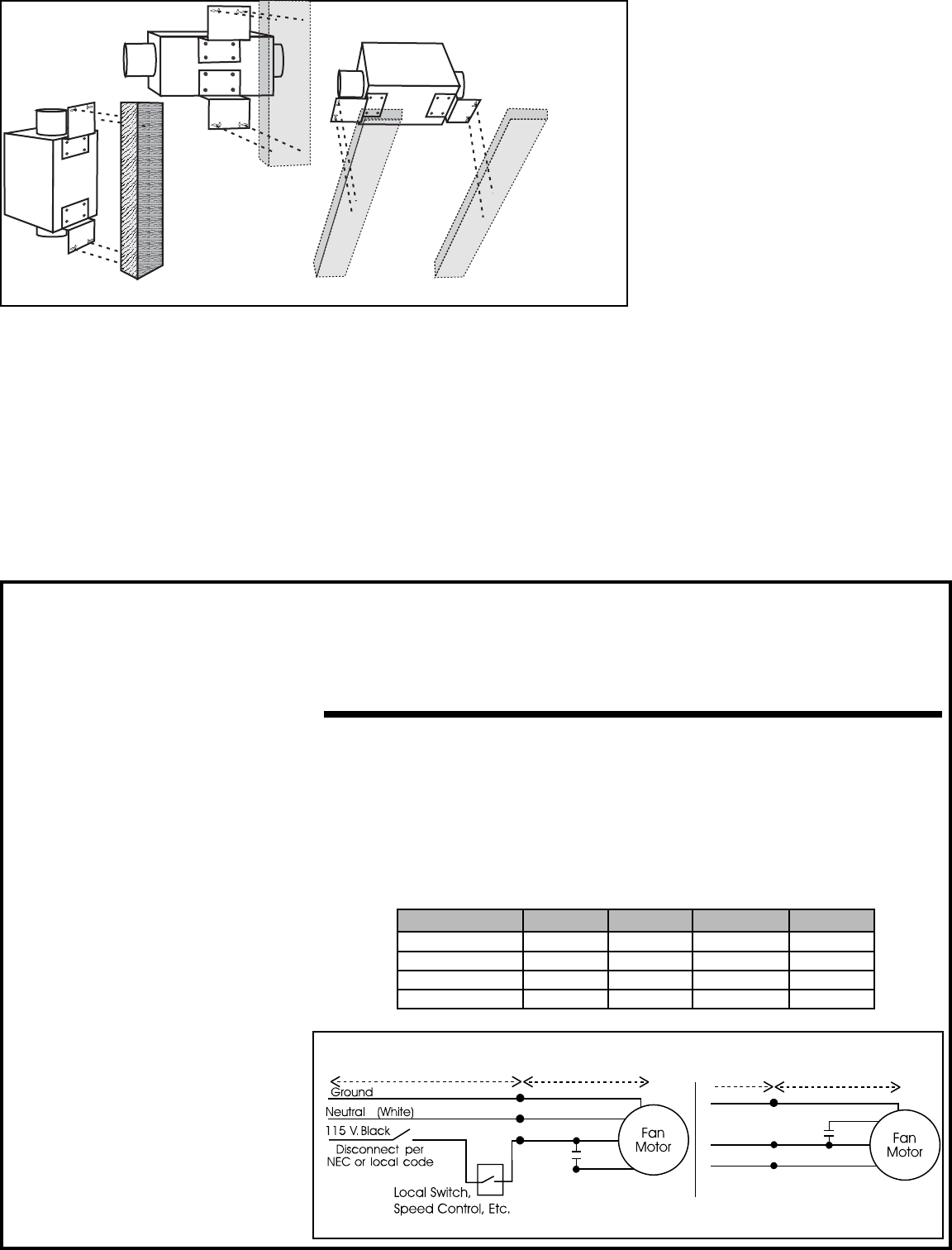

ELECTRICAL

FANS MAY BE MOUNTED VERTICALLY OR HORIZONTALLY

Provide disconnect switch in vicinity of fan, to

permit servicing fan, in accordance with NEC

and local codes.

Depending on the desired mode of operation,

switches may be simple on-off switches,

motor speed controls, timer switches, time

delay, time of day cycle timers, dehumidistats,

F. NEVER place a switch where it can

be reached from a tub or shower.

occupancy sensing controls, controllers,

etc., provided they are rated for motor duty

and meet the nameplate electrical ratings

of the motor. (Additional application wiring

diagrams are available illustrating a variety

of controls for use with RDF fans by calling

the factory at 1-800-255-7749.)

ELECTRICAL DATA

Base Model Volts Max Amps Max Watts RPM

RDF 8-8IP 115 0.19 21 2500

RDF 8-8MAX 115 0.29 34 3135

RDF 12-8IP 115 0.34 41 2200

RDF 12-8 115 0.53 59 2960

RDF 8MAX

and RDF 12-8

RDF 8-8 IP and

RDF 12-8 IP