Belshaw Bros., Inc. • 1750 22

nd

Ave. S. • Seattle, WA 98144 • Phone 206-322-5474 • Fax 206-322-5425

718LCG, 724CG, and 734CG Gas Fryers MN-1141EN 3

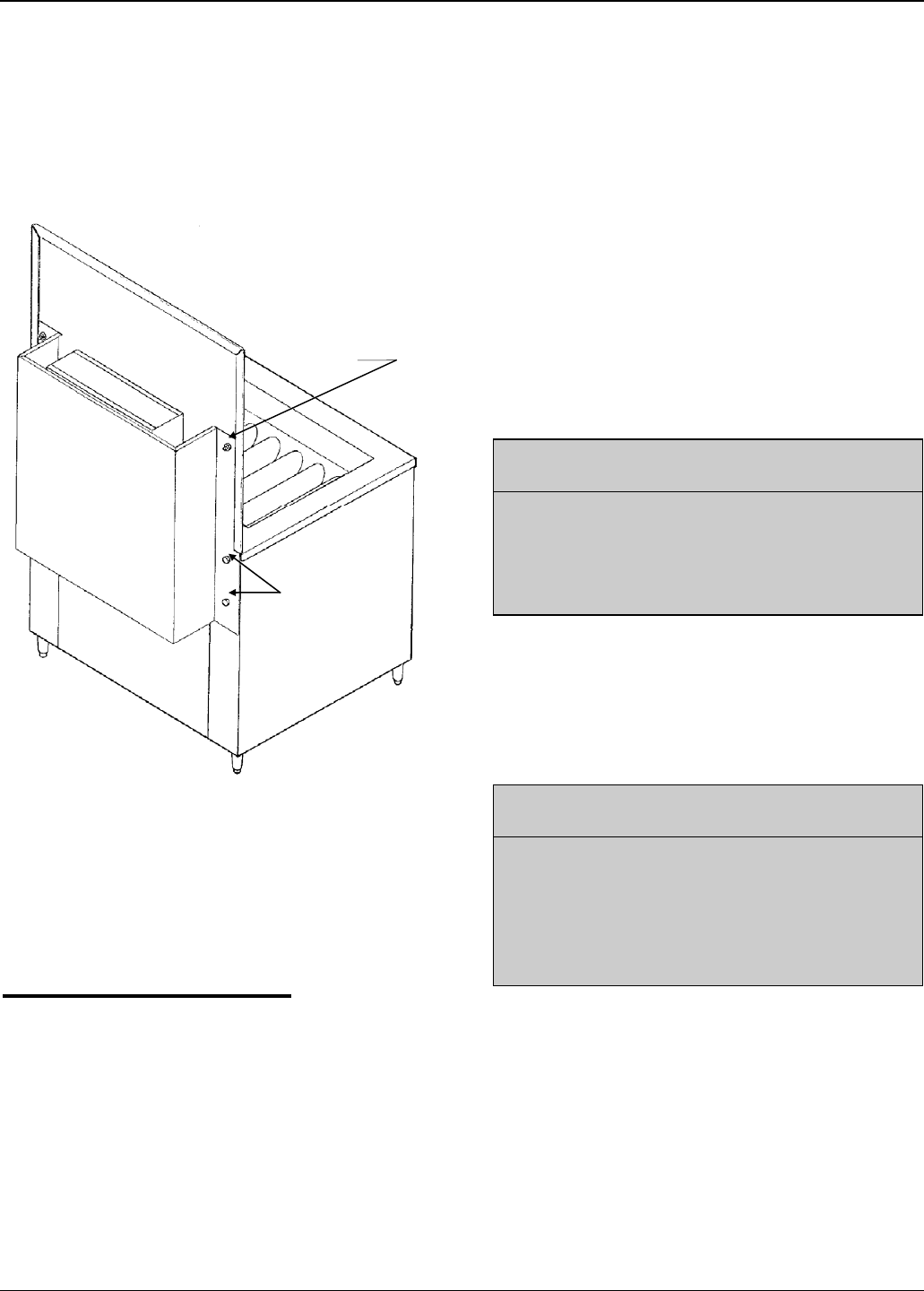

3. Put the heat shield and splash shield on the

fryer. They slide over the flue stack, and the

back of the kettle slides between the heat

shield and the splash shield. The mounting

holes in the heat shield and the fryer cabinet

must line up. See Figure 1-2.

Figure 1-2. Installing the Heat Shield and

Splash Shield.

4. Fasten the heat shield to the fryer cabinet

using the four hex-head tek screws provided.

Installing the Fryer

1. Make sure the power requirements of the

machine, found on the data plate, match

your power source.

2. Using a fork lift or pallet jack, lift the fryer

cabinet and screw each leg in as far as it will

go.

3. Set the fryer cabinet on a flat, dry floor.

4. Level the fryer. Follow these steps:

a. Check to see if the fryer is level. To do

so, place a level across the top of the

fryer cabinet.

b. If the fryer is not level, lift the fryer

using a fork lift or pallet jack, and turn

the legs to adjust them.

c. Using the fork lift or pallet jack, lower

the fryer to the floor. Be sure that all the

legs rest on the floor when the fryer is

level.

5. Bolt the fryer to the floor. The foot of each

leg has two holes in it for this purpose.

WARNING

To avoid serious burns, other injury, or

death, make sure the fryer is securely

fastened to the floor so it will not tip or fall

over.

6. If you want to perform pressure testing on

the building’s gas supply system at pressures

greater than 0.5 psig/3.45 kPa, do so now,

before you connect the fryer to the gas

supply.

CAUTION

To avoid damaging the fryer, do not

perform pressure testing on the building’s

gas supply system at pressures greater than

0.5 psig/3.45 kPa when the fryer is

connected to the that system.

7. Connect the fryer to the gas supply, as

follows:

a. Make sure the gas line to the fryer is the

right size. If it is too small, the gas

pressure at the burner manifold will be

too low, resulting in slow heat recovery,

delayed ignition, and pilot outage. (The

heat

shield

splash

shield

hex-head

sheet metal

screws

10-24 x 3/8

hex-head

screw