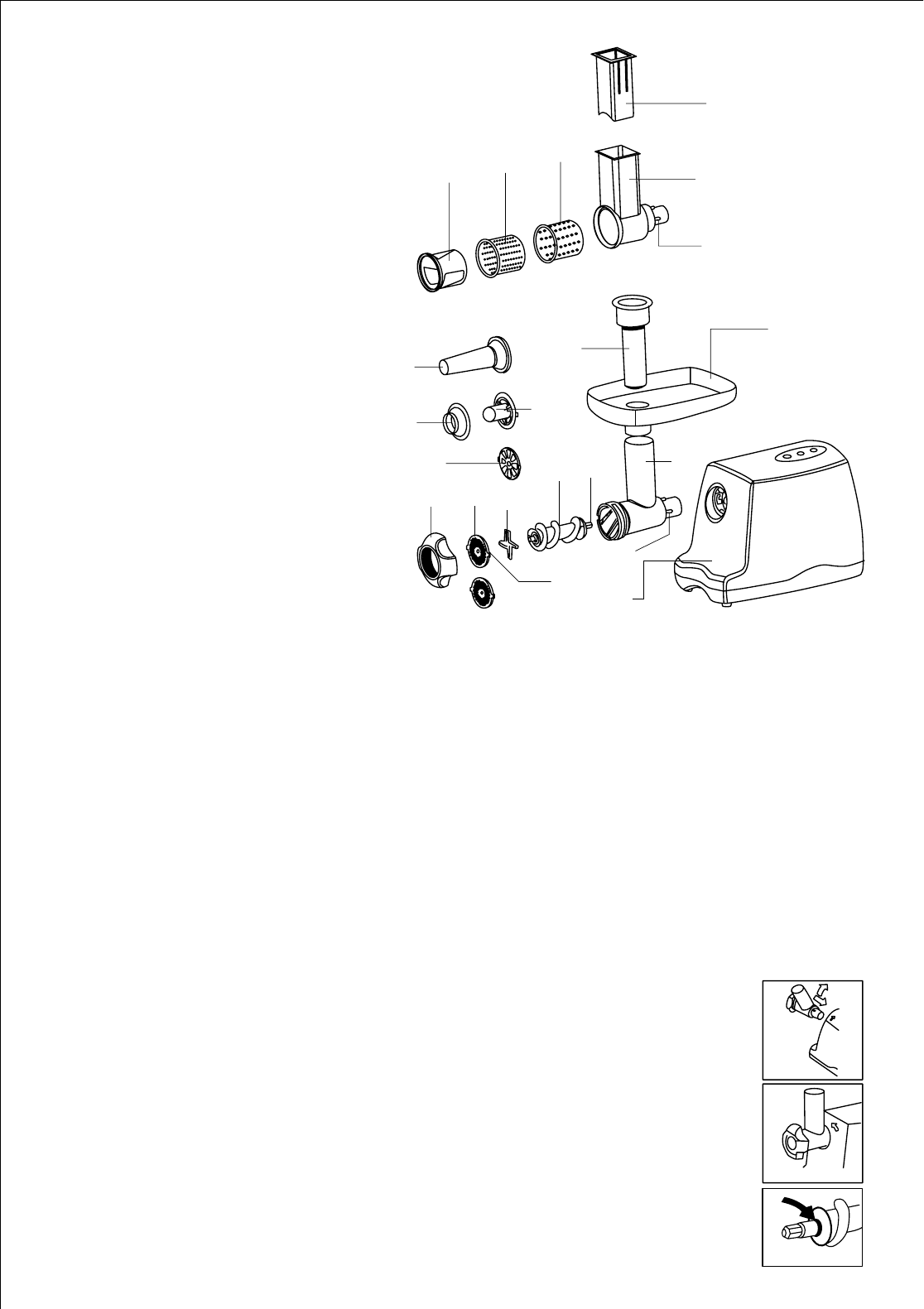

Parts Identification

1. Motor unit

2. Grinder head with filling shaft

2a. Notch in the metal housing

3. Worm

4. Blade

5. Coarse & fine disc

5a. Protrusion in the disc

6. Nut

7. Tray

8. Round pusher

9. Sausage disc

10. Kebbe attachment

(10a) Kebbe shaper

(10b) Kebbe cone

11. Sausage stuffer

12. Shredder attachment

13. Square pusher

14. Coarse shredder

15. Fine shredder

16. Slicer

17. Bayonet

Product Features :-

1700W as locked motor power - for meeting the toughest of meat mincing.

Stainless Steel Blades and feeder - screw provides durability and efficiency

One speed operation - for all mincing and grating operations

Reverse speed - assists in removing all blockages during operation.

Aluminium tray - for ease of feeding

Kebbe Attachment - assists in making of kebbes

Multi purpose food shredding and slicing attachment - to meet all your daily needs

Cord Winding facility - to avoid litter of power cord.

Sausage stuffer - for making sausages.

1

2

7

8

9

10a

10b

17

11

16

15

14

12

17

13

2a

3

4

5

5a

6

Fig. 1

Fig. 2

Using your Meat Mincer

Your Meat Mincer is intended for indoor household use only. Kindly ensure that all the packaging material

has been removed from the unit. Remove any instruction, sticker etc. Ensure that the ratings on your

mincer are the same as the line voltage in your home.

Wash all the parts other than the base unit in warm sudsy water and allow to dry. Your

meat mincer is not only for grinding meat but can also be used for grinding vegetables,

making Kebbe and sausage as well.

Assembly of Mincer attachment:

1. Insert the mincer head into the groove on the base unit. The mincer head is joined to the

base unit with a bayonet lock mechanism. Hold the mincer head with one hand keeping

the food funnel at an angle of 45º in clockwise direction (Figure 1).

2. Turn the grinder head anti-clockwise in the direction of the upright arrow until the filling

shafts snaps into place in an upright position (Figure 2).

3. Insert the worm with the long end into the mincer head and turn slightly until it is

securely coupled with the motor shaft.

NOTE :- Ensure that the O-ring on the rear of the worm is in place.

O-ring