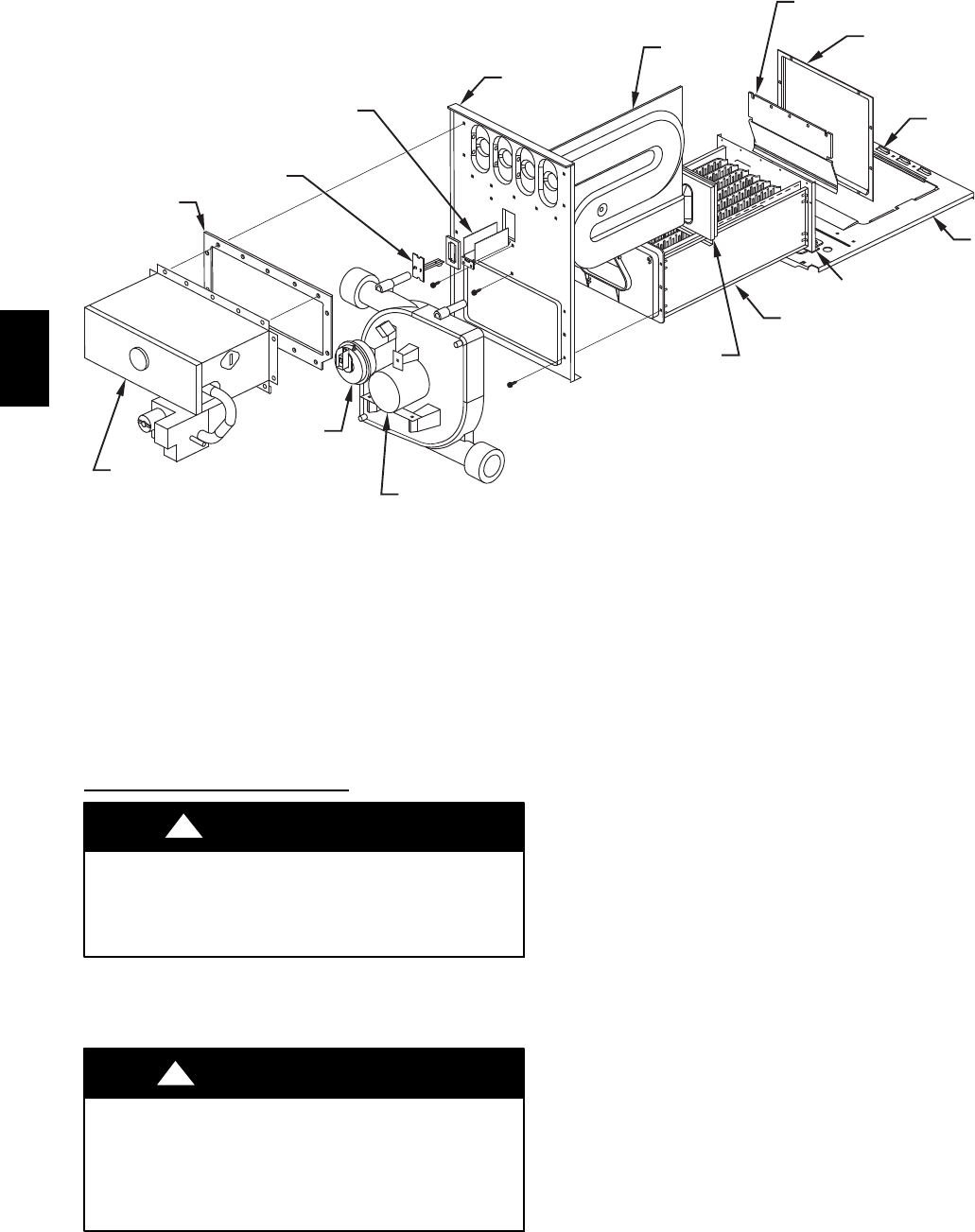

4

COUPLING

BOX

T-TABS

BLOWER

SHELF

PRESSURE

SWITCH

BURNER

ENCLOSURE

AND GAS VAVLE

INDUCER

MOTOR

BURNER

ENCLOSURE

GASKET

MAIN LIMIT

MAIN LIMIT

SHIELD

PRIMARY CELL

INLET PANEL

PRIMARY

CELL

CONDENSING

HEAT EXCHANGER

ASSEMBLY

PRIMARY CELL

OUTLET PANEL

COLD SPOT

BAFFLE

NOTE: ACTUAL COMPONENT LOCATION MAY VARY

DEPENDING ON MODEL & SERIES.

CONDENSING

HEAT EXCHANGER

CELL REAR PANEL

A05128

Fig. 3 -- Expanded View of Heat System Components in Upflow Orientation

NOTE: If gasket is damaged in any way, it must be repaired. To

repair, apply a small bead of G.E. RTV 162, G.E. 6702, or

Dow--Corning RTV 738 to damaged gasket area. Apply sealant

releasing agent such as PAM cooking spray or equivalent (must

not contain corn nor canola oil, halogenated hydrocarbons or

aromatic content to prevent inadequate sealing) to burner

enclosure mating surface.

4. Connect pressure tube to intake housing.

Reinstall Whole Cell Panel

Assembly

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

Whole cell panel assembly is heavy. Get help to lift and

install.

CAUTION

!

1. Install whole cell panel assembly with heat exchanger,

burner box, inducer assembly, J--box (if applicable), and

control center (if applicable) through front of furnace.

FIRE AND UNIT OPERATION HAZARD

Failure to follow this warning could result in personal

injury, death and / or property damage.

DO NOT cut or tear foil face insulation. If cuts or tears

occur, repair insulation with foil tape.

!

WARNING

2. Secure whole cell panel assembly to blower shelf by in-

stalling two screws through blower housing (four screws

on 120 and 140 sizes) and two screws next to blower

housing.

NOTE: When reinstalling condensing heat exchanger assembly,

the lower flange of the condensing heat exchanger cell rear panel

must engage on the T--tabs in rear blower shelf. (See Fig. 3.)

3. Install three screws to each side of inlet cell panel and into

cell panel supports.

4. If previously removed, reinstall control center in casing

flange.

5. If control center is located in burner compartment or fur-

nace, reinstall blower motor leads, transformer wires, door

switch wires, and auxiliary limit switch wires (if present)

through blower shelf and grommet.

6. If control is located in blower compartment of furnace,

pull wires to flame sensor, hot surface igniter, overtemper-

ature switch, gas valve, pressure switch(es), inducer motor,

limit switch, and J--box through blower shelf.

7. Install J--box.

8. Reattach wires to control center or components. See wir-

ing diagram on furnace for proper attachment.

9. Reinstall condensate trap where previously installed fur-

nace casing or blower shelf.

10. Reconnect condensate trap drain tubes. See tubing dia-

gram on furnace for proper tube location.

11. Connect field drain to condensate trap.

NOTE: Ensure tubes are not kinked or pinched, as this will

affect operation.

12. Connect vent pipe by inserting pipe into coupling, elasto-

meric (rubber) coupling, and then fully into inducer hous-

ing outlet.

13. Connect combustion--air intake pipe to intake housing and

install screw to secure. Do not use RTV unless previously

used.

14. Install top filler panel.

15. Install gas supply pipe to gas valve using backup wrench.

320720