30

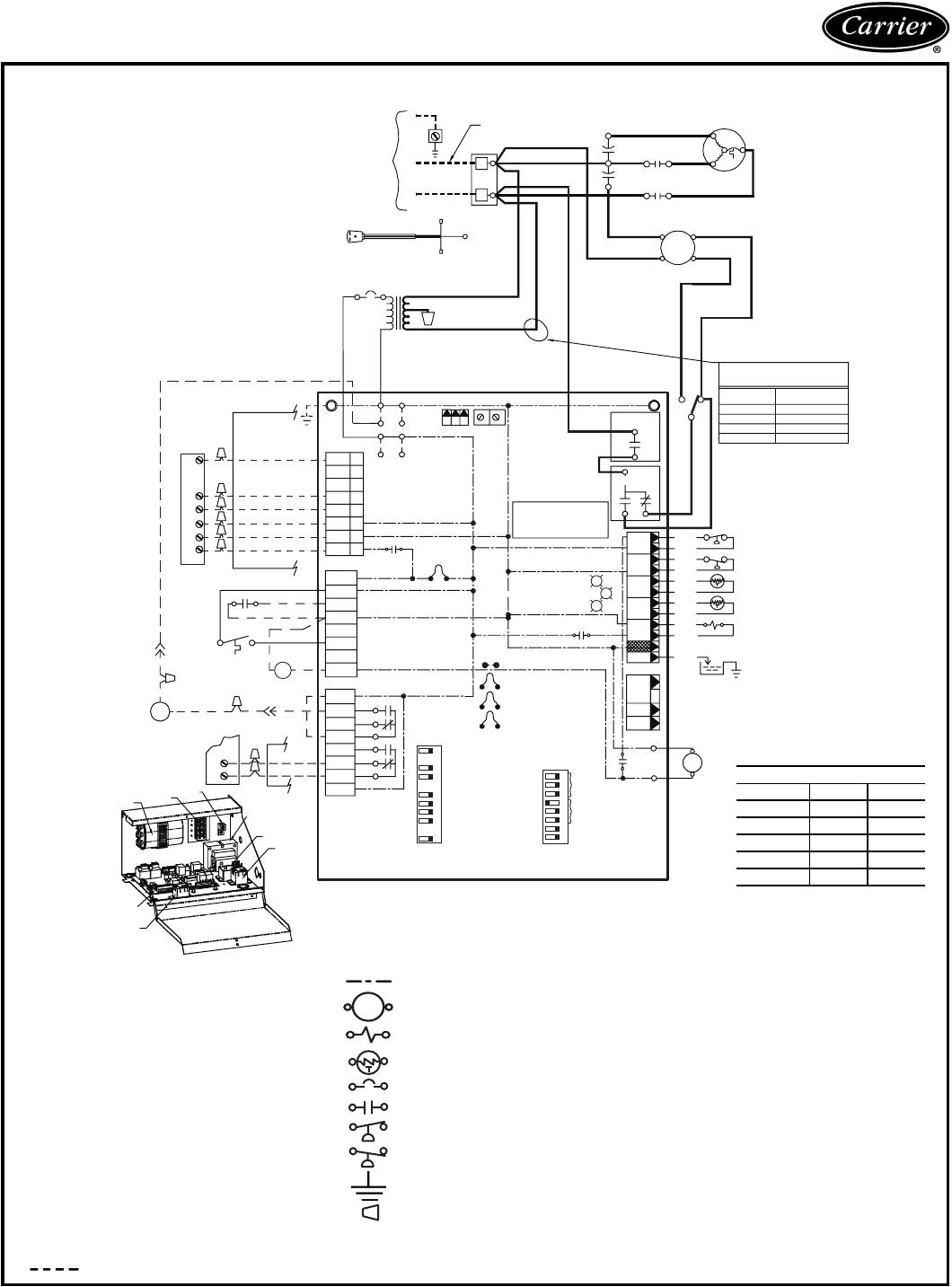

Typical wiring schematics (cont)

AL — Alarm Relay Contacts

BR — Blower Relay

CAP — Capacitor

CB — Circuit Breaker

CO — Sensor, Condensate Overflow

CR — Compressor Relay

DM — Damper Motor

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

FSS — Fan Speed Switch

HP — High-Pressure Switch

JW1 — Jumper Wire for Alarm

LOC — Loss of Charge Pressure Switch

NLL — Night Low Limit

PB — Power Terminal Block

PBS — Push Button Switch

PM — Performance Monitor

RVS — Reversing Valve Solenoid

TRANS — Transformer

WV — Water Valve

---------- Field Line Voltage Wiring

Field Low-Voltage Wiring

REMOTE-MOUNTED THERMOSTAT WITH DELUXE D CONTROLLER

Printed Circuit Trace

Relay/Contactor Coil

Solenoid Coil

Thermistor

Circuit Breaker

Relay Contacts-N.O.

Switch-High Pressure

Switch-Low Pressure

Ground

Wire Nut

Mate-N-Lock

>

>

CLOSED=UNOCCUPIED

Y

G

DELUXE

D

CONTROL

BR 1

(LO)

CR

CAP

PB

GROUND

LUG

TRANSFORMER

BR 2

(HI)

COMPR.

RELAY

CCG

YEL

HP

LOC

FP1

FP2

RV

CO12

P7

24V

DC

EH1

EH2

P6

HP

LOC

FP1

FP2

RVS

CO

SEE

NOTE

4

RED

RED

BLU

BRN

GRY

GRY

VIO

VIO

BRN

ORG

NOT USED

1

2

3

4

5

6

7

8

9

10

CC

BRN

YEL

CR

1

0

STATUS

DELUXE D

MICROPROCESSOR

CONTROL LOGIC

TEST

FAULT

R

RV

RELAY

TEST

PINS

JW3

FP1 LOW

JW2

FP2 LOW

SEE

NOTE 4

JW1

LP N.O.

COM

NO

NO NC

COM

FAN

SPEED

RELAY

FAN ENABLE

RELAY

GRY

Y1

Y1

W1

O/W2

G

R

C

AL1

COMPRESSOR

COOLING

FAN

24 VAC

COMMON

ALARM

CLASS 1 WIRING

REQUIRED INSIDE

Y

O

G

R

C

X1

CLASS 1 OR 2 WIRING

ACCEPTABLE

OUTSIDE

CONTROL BOX

TYPICAL HEAT

PUMP T-STAT

SEE NOTE 5

BRN

SEE

NOTE 7

AL2

R

NSB

C

ESD

OVR

H

A

R

NO1

NC1

COM

NO2

NC2

COM

R

P1

P2

P3

RED

BRN

WHT

YEL

RED

YEL YEL YEL

BRN

BRN

ORG

DM

OV

OV

OVERRIDE

OVERRIDE

OVERRIDE

WITH DIGITALT-STAT

TIME CLOCK

NLL

WV

ALARM

RELAY

SEE

NOTE 6

C

R

JW4

AL2 DRY

COM2 COM1

RCS

SC

1

2

3

4

5

6

7

8

ACC1

RELAY

ACC2

RELAY

BLU

S1

DIP SWITCH

PACKAGE

PM: DISABLE/

ENABLE

UNIT STAGE: 2/1

T-STAT: HEAT COOL/

HEAT PUMP

RV ON B/RV ON O

DEHUMID/NORMAL

NOT USED

BOILERLESS:

ENABLE/DISABLE

BOILERLESS:

40°F/50°F

1

2

3

4

5

6

7

8

OFF ON

S2

DIP SWITCH

PACKAGE

ACC1

FUNCTIONS

ACC2

FUNCTIONS

H: HI FAN/DEHUMID

NOT USED

1

2

3

4

5

6

7

8

OFF ON

BLK

ORG

230V

24V

TRANS

CB*

POWER SUPPLY

REFER TO DATA PLATE

USE COPPER CONDUCTORS ONLY.

SEE NOTE 2

REFER TO DISCONNECT

BOX FOR OPTIONAL

POWER SUPPLY CONNECTION

GROUND

L2

L1

OPTIONAL

CORD

CONNECTION

RED

NEUTRAL ON 265V

SYSTEMS

L2 (ribbed)

GROUND

L1 (plain)

PB

1

2

H

C

F

CAP

RED

RED

6

8

2

4

BLK

BLK

R

S

C

CR

BLU

COMPRESSOR

BRN

YEL

2

1

BM

B (HIGH)

A(LOW)

RED

BLK

115

208

230

265

WHT

RED

ORG

BRN

LEAD COLOR

VOLTAGE

TRANSFORMER PRIMARY

LEAD COLORS

YEL

SEE

NOTE 3

1

3

2

FSS

GRY

LEGEND

BLOWER MOTOR WIRING

UNIT SIZE POLE A POLE B

07 5 3

09 5 4

12 4 3

15 4 3

19 4 3

*Optional wiring.

NOTES:

1. Compressor and blower motor thermally protected

internally.

2. All wiring to the unit must comply with local codes.

3. Transformer is wired to 115-V (WHT) lead for 115/1/60

units, 265-V (BRN) lead for 265/1/60 units or 208-V

(RED) lead for 208/1/60 units.

For203/1/60switchREDandORGleadsatL1and

insulate RED lead.

Transformer is energy limiting or may have circuit

breaker.

4. FP1 thermistor provides freeze protection for WATER.

When using ANTI-FREEZE solutions, cut JW3 jumper.

5. Typical heat pump thermostat wiring shown. Refer to

thermostat Installation Instructions for wiring to the

unit.

6. 24-V alarm signal shown. For dry alarm contact, cut

AL2 DRY (JW4) jumper and dry contact will be avail-

able between AL1 and AL2.

7. Transformer secondary ground via Deluxe D board

standoffs and screws to control box. (Ground available

from top two standoffs as shown.)