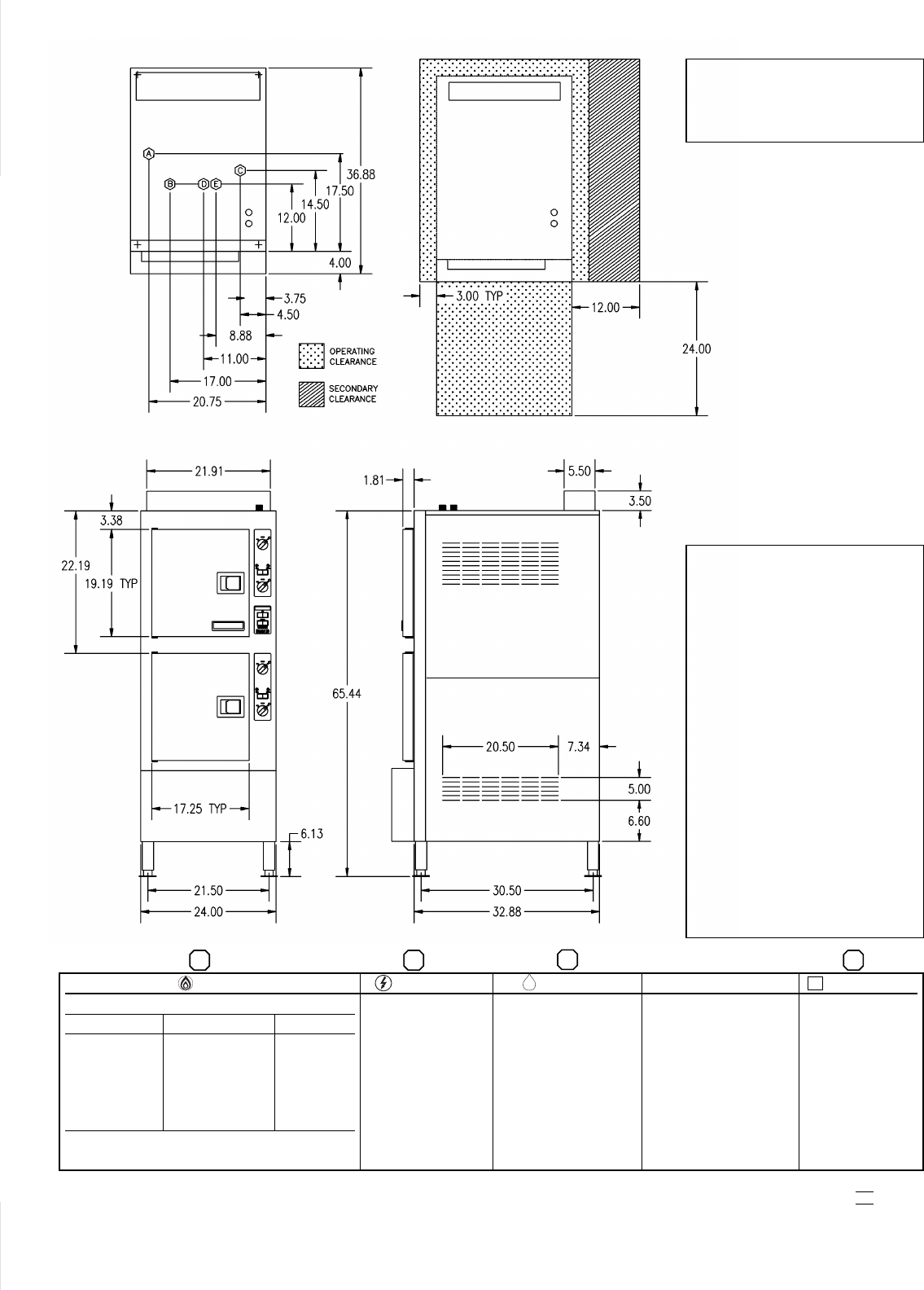

(NOT TO SCALE)

SECT. IV PAGE 14

0402

Litho in U.S.A.

GAS ELECTRIC COLD WATER CLEARANCE DRAINAGE

1

1

⁄

4

˝ IPS line size,

3

⁄

4

˝ (13mm) connection 120V-1Phase, 60 Hz. 35 psi minimum RIGHT = 3˝ operating, 1

1

⁄

2

˝ dia.

NATURAL PROPANE BTU 2 Blowers & Controls 60 psi maximum 12˝ if adjoining wall or Do not connect other

Piping

3

⁄

4

˝ N.P.T. Piping

3

⁄

4

˝ N.P.T. 72,000 each 150 watts each LEFT = 3˝ units to this drain

Supply pressure Supply pressure Generator, One (E) 1/4" dia. REAR = 3˝

4.50˝ W.C.Min. 11.00˝ W.C.Min. 144,000 total NPT for Generator Allow 6˝ space min. Drain must be vented

14.00˝ W.C.Max. 14.00˝ W.C. Max. from rear and sides

One (D) 1/4" dia when located near Do not use PVC pipe

Manufacturer must be notified if unit will NPT for Condenser combustible walls

be used above 2,000 feet

C

D

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers.Included among those approval agencies are UL/NSF#4 and CSA (AGA, CGA).

Each Compartment has

capacity for:

• Five, 12˝ x 20˝ x 2

1

⁄2˝ deep

Cafeteria Pans.

WATER QUALITY

REQUIREMENTS

The quality of water varies

greatly from region to region.

Steam equipment generators

must be drained daily and

chemically descaled periodically

to ensure proper operation. To

minimize service problems

caused by the accumulation of

minerals and chemicals in water

review the following quality

guidelines with a local water

treatment specialist. Inlet water

that is beyond these specified

guidelines should be treated to

achieve these acceptable limits.

Total Dissolved Solids less than

60 ppm, Alkalinity less than 20

ppm, Silica less than 13 ppm,

pH factor greater than 7.5,

Chlorine less than 30 ppm.

Right - 3”, Left - 3”,

Rear -3”

(12” on control side if adjoining

wall or equipment is over 30”

high for service access)

Contact factory

for variances to

clearances.

A B C

DE