STEAM

All steam plumbing to and from the kettle and steam

boiler should be thoroughly cleaned and inspected for

dirt and debris before final connection to the kettle are

made.

Check the rating plate for the maximum steam pressure

that your kettle is rated for. If the steam supply pressure

exceeds the rated pressure, a pressure reducing valve

is required. The steam inlet is at the right side of the

kettle, as seen from the front.

CONDENSATE

A steam condensate trap must be plumbed to a drain,

using minimum 1/2" NPT plumbing. The condensate line is

limited to a maximum rise of 10 feet in order for the steam

pressure to adequately force the condensate through the

plumbing. Any higher rise requires a pump.

If the steam boiler to which this kettle is installed has a

condensate return (closed loop system), a 1/2" steam

strainer, a 1/2" steam trap, and a 1/2" check valve must be

installed on the output (condensate) side of the kettle.

FOR POWER TILT UNITS ONLY

NNOOTTEE

: Ensure the electrical supply matches the kettle's

requirements as stated on the rating label.

This kettle is built to comply with CE standards. Many local

codes exist, and it is the responsibility of the owner and

installer to comply with these codes.

NNOOTTEE

: Maximum voltage for LVD is 440 volts for CE

marked appliances.

POTABLE WATER

The water faucet (optional) with swing spout, requires 1/2

inch O.D. copper tube plumbing for hot or cold water

supplies to the faucet (SPK - cold water connection only,

DPK - hot and cold water connection).

FINAL INSTALLATION CHECK

1. Partially fill the kettle with water.

2. Slowly turn the steam supply valve's knob to the

open position.

3. Release the safety valve, ensuring that the steam

escapes freely. Stay clear of steam exhaust when

releasing the safety valve.

4. Observe that the water in the kettle comes to a

boil.

5. Close the steam supply valve.

6. Drain off the water in the kettle.

CLEANING

After installation the kettle must be thoroughly cleaned

and sanitized prior to cooking. See CLEANING

INSTRUCTIONS for detailed information and suggested

cleaners.

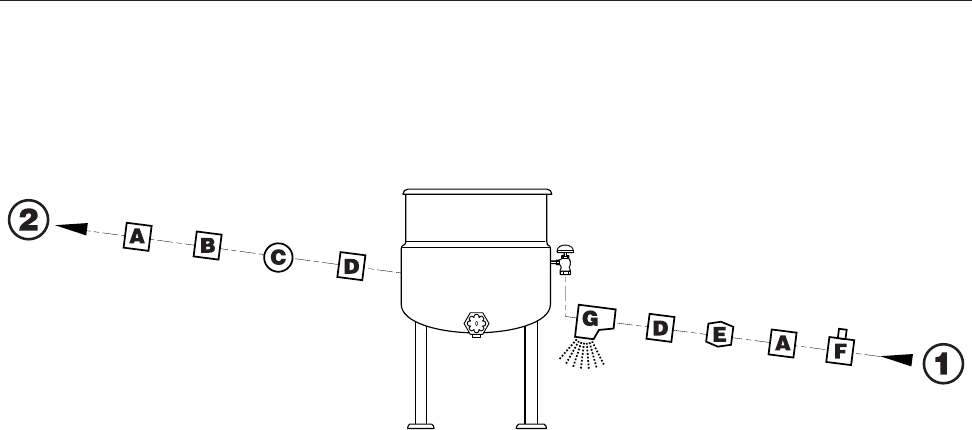

RECOMMENDED PIPING

SCHEMATICS

(all service connections shown supplied by others)

1 Steam In

2 To Drain or Boiler Condensate Line

A Union

B Check Valve

C Steam Trap

D Strainer

E Pressure Reducing Valve

F Shut Off Valve

G Pressure Relief Valve