3. Remove Console Cover and Access Panel.

4. Pull Pressure Relief Valve Ring open to insure

vessel is not pressurized.

5. Remove 1/4" copper tubing and reducer bushing.

6. Remove Drain Plug cap and allow water to drain.

7. Replace Drain Plug cap and add water until it

shows on sight glass.

8. Repeat steps 6 & 7 until water drains clear.

9. Apply a thread sealant (i.e. Teflon tape) to the Drain

Plug cap and replace.

10. Add distilled water and rust inhibitor using a funnel

if necessary. Fill the unit to the high level mark on

the Sight Glass.

11. Apply a thread sealant (i.e. Teflon tape) to the

reducer bushing threads and replace.

12. Replace Console Cover and Access Panel.

13. Restore power to unit at the fused disconnect

switch.

14. The kettle must now be vented. (Refer to the

KETTLE VENTING INSTRUCTIONS on page #27).

KETTLE JACKET FILLING &

DRAINING PROCEDURES

Under normal circumstances the kettle does not require

the draining of all fluid. If the red “low water” light is on,

follow the RESERVOIR FILL PROCEDURES (page #28)

in this manual.

If unit must be drained follow the procedures described

on the following pages.

Use only a mixture of water and rust inhibitor to refill

kettle jacket (see instructions below).

Contact your local water treatment company and

purchase rust inhibitor with the specifications described

below.

Recommended Corrosion

Inhibitors for Closed Systems

DESCRIPTION

Recommended for our units is a blend of SODIUM

NITRITE and BORAX for corrosion inhibition of ferrous

metals and axoles for copper and copper alloy

corrosion protection. Product should be formulated for

hot or cold closed recalculating water systems.

Source the chemicals stated above from your local

water treatment company. Mix only with water and

follow manufactur

es recommended mixing rate.

DISPOSAL OF INHIBITOR

Do not dispose of chemicals in any system which may

discharge into water supplies used for drinking or

washing or that could accidentally discharge into such

systems, or into stream accessible to animals.

Follow all Federal, State and local codes when

disposing of product.

WARNING: IMPROPER REFILLING OF

KETTLE JACKET WILL RESULT IN

IRREVERSIBLE DAMAGE TO UNIT.

30

DANGER: EXTREMELY

HOT SURFACES.

WORK ONLY ON COLD

KETTLE.

DANGER: PRESSURE RELIEF

VALVE WILL EXHAUST HIGH

TEMPERATURE STEAM. CONTACT

WITH SKIN COULD RESULT IN

SERIOUS BURNS. KEEP FACE,

HANDS AND BODY CLEAR OF DISCHARGE.

DANGER: WORKING ON MACHINES

WITH POWER COULD RESULT IN

SEVERE ELECTRICAL SHOCK.

DANGER: EXTREMELY

HOT SURFACES.

WORK ONLY ON COLD

KETTLE.

WARNING: IMPROPER REFILLING OF

KETTLE JACKET WILL RESULT IN

IRREVERSIBLE DAMAGE TO UNIT.

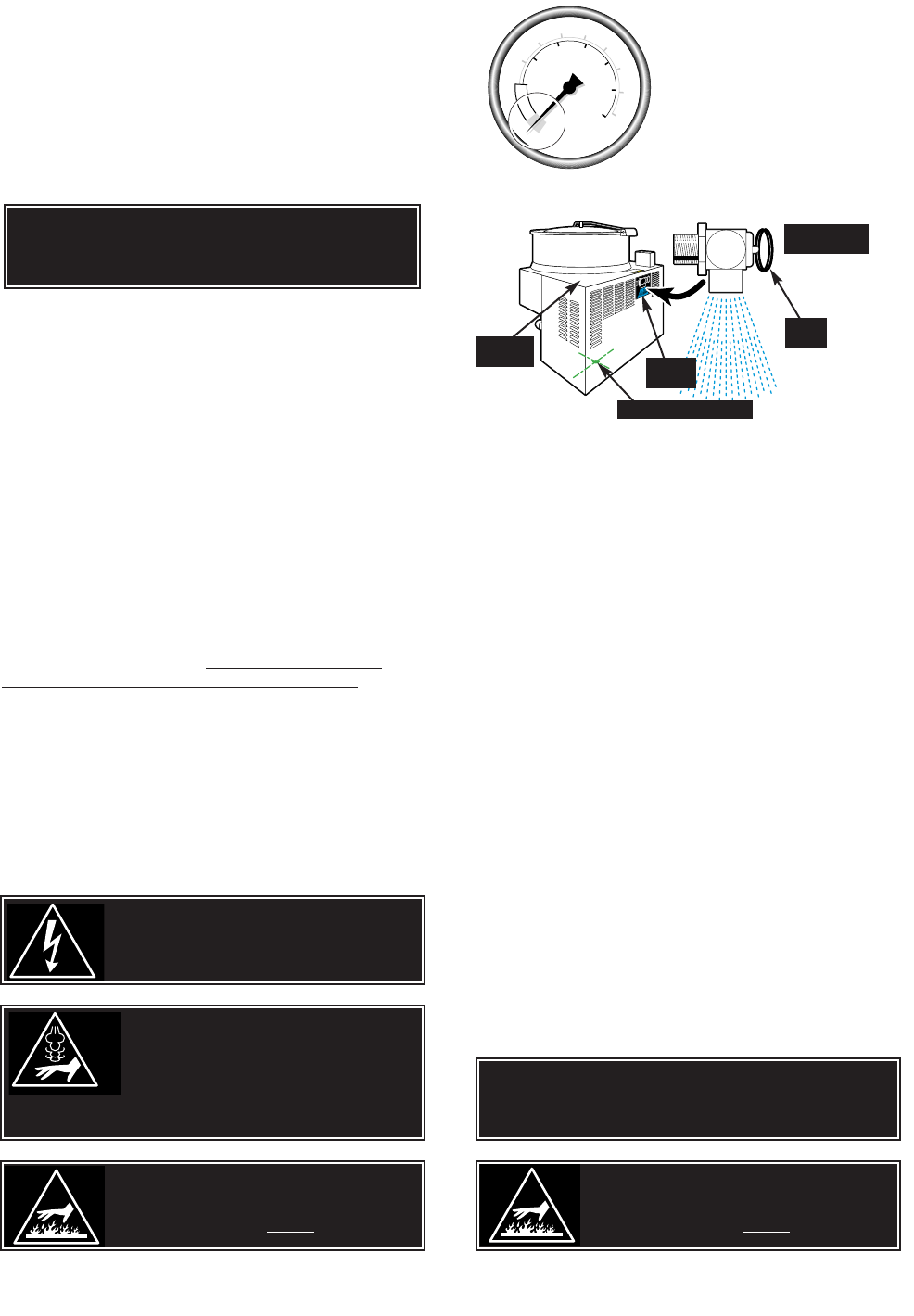

Pressure

Relief Valve

Access

Panel

Drain Plug Location

Valve

Ring

Console

Cover

1. Ensure kettle is at room

temperature and pressure

gauge showing zero or less

pressure.

2. Shut off power to the kettle

at the fused disconnect

switch.

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R