AIR LINE LUBRICATOR OIL

FILLING PROCEDURE

1. Disconnect air supply and bleed system.

2. Remove cover on console (see PARTS LIST -

PNEUMATIC COMPONENTS).

3. Check for oiler location.

4. Inspect oil level in

bowl.

5. Remove filler cap.

6. Add mineral oil as

required.

7. Replace filler cap

and console cover.

Oiler

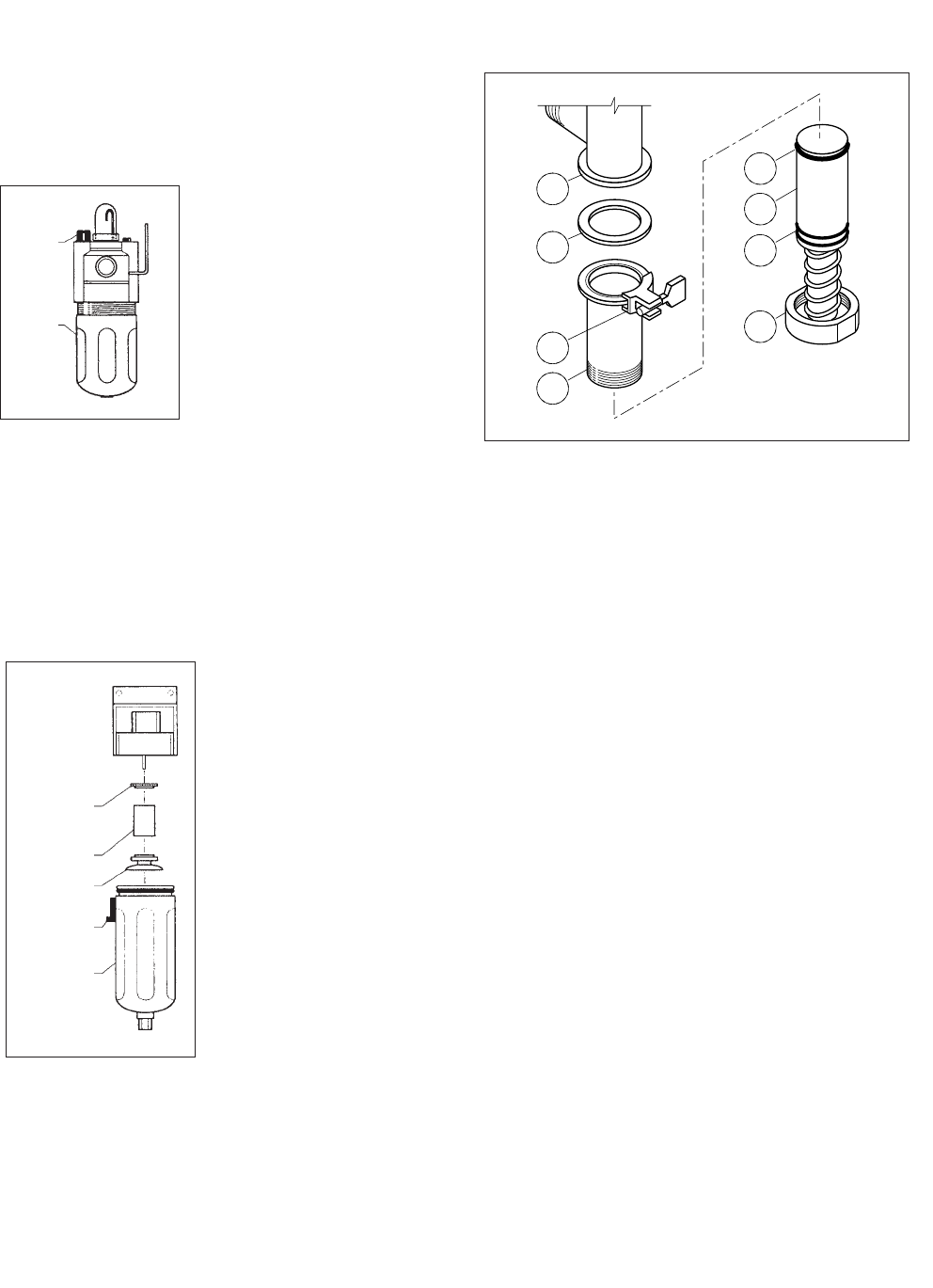

AIR FILTER REPLACEMENT

PROCEDURE

1. Disconnect air supply and bleed system.

2. Remove cover on console (see Parts List -

Pneumatic Components).

3. Check for filter location.

4. Push lever down

and rotate bowl/

guard assembly

1/8 turn.

5. Push down on

bowl/guard

assembly

and remove.

6. Unscrew baffle

and remove filter

element, inspect

and replace filter

if required.

7. Replace filler cap

and cover.

Air Filter

AUTOMATIC DUMP VALVE

Replacing “O” rings (8):

Automatic Dump Valve

1. Disassemble valve as per daily cleaning

instructions.

2. Holding lower valve body (6), unscrew valve

bottom (7).

3. Pull lower valve body out from cylinder body.

4. Replace "O" rings (8), as required.

5. Coat cylinder body and "O" rings with cooking

oil or food-safe grease.

6. Reassemble.

STEAM TRAP

Each kettle is equipped with a steam trap in the

line of the kettle outlet to the drain, to remove line

condensate that forms inside the steam jacket. A

good steam trap at startup releases air and wet

steam into the drain line for a few minutes, then

holds the steam jacket. During cooking, the trap

periodically releases accumulated condensate. If

the kettle's cooking performance becomes

inadequate after long use, replacement of the

steam trap with a new one may restore kettle

operation to peak efficiency.

5

2

6

3

7

8

4

1

Filler

Cap

Bowl

Deflector

Filter

Element

Baffle

Lever

Bowl/Guard

Assembly