PERIODIC MAINTENANCE

Checking the control system

Checking the connections

supply must be turned on.

connections. The appearance of bubbles indicates a

leak and should be repaired immediately!

Checking the LP gas pressure

readjusted if pressure is incorrect. The correct operating pres-

at the test port, just ahead of the burner jet.

Cleaning the ue bafe and burner

of the burner.

Turn off the refrigerator.

supply to the refrigerator.

Turn off the manual shut off valve.

burner mounting screws and then, the burner as-

sembly.

3.

-

not properly

burner with compressed air.

compressed air.

einstall and tighten the burner jet.

-

couple is positioned properly (tip of thermocouple

extends over two slots of burner).

Turn on the manual gas shut off valve.

non-corrosive bubble solution.)

7.

MAINTENANCE & SERVICE

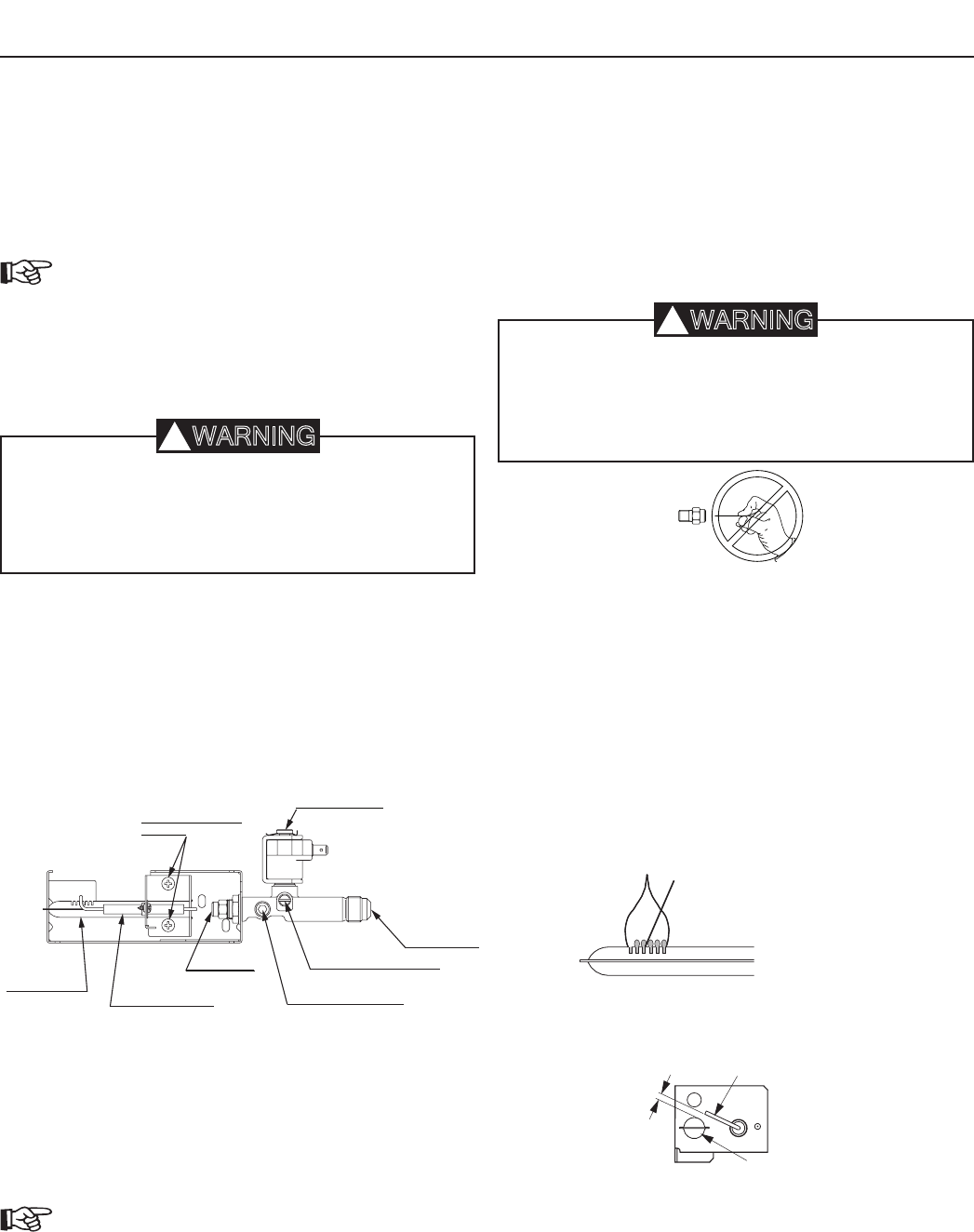

BURNER TUBE .

SPARK ELECTRODE

BURNER JET

BURNER MOUNTING

SCREWS

PRESSURE TEST PORT

MANUAL SHUT OFF VALVE

(Shown in open position)

INLET FITTING

SOLENOID VALVE

Gas equipment assembly

Electrode

Burner tube

1/8” to 3/16”

(3-5 mm)

4HEFLAMESHOULDBE

CLEARBLUEOVERTHE

SLOTSOFTHEBURNER

FIRE HAZARD. Do not use a wire or pin when

cleaning the burner jet as damage can occur to

the precision opening. Failure to heed this warn-

ing could cause re resulting in personal injury.

WARNING

!

EXPLOSION HAZARD. Never use an open

ame to check for gas leaks. Failure to heed this

warning could cause an explosion resulting in

death or severe personal injury.

WARNING

!