Installation Guide

Beer Dispenser

866-319-5473

For assistance, please call:

2

8

Mount CO

2

Cylinder

Now mount the CO

2

cylinder

holder(9) to the cabinet. Match

up the holes on the holder with

the four screws jutting out of the

back of the cabinet and slide the

holder down to lock it in place.

Position the CO

2

regulator(6) in

the holder so that you will be

able to read the numbers on the

gauge and have easy access to

the shut-off valve.

14

Position Keg

Place the metal keg floor support(11) back into the cabinet.

Carefully tilt beer keg(17) and rest the edge on the keg floor

support on the bottom of the interior cabinet. Slide the keg in

slowly, ensuring that it is properly located, and all hoses are

clear of obstructions. Close door and enjoy.

5

Install Handle & Faucet

Screw the black faucet handle(1) onto

the faucet (2). Line up the metal “teeth”

on the faucet with the metal “teeth” of

the faucet adapter on the front of the

tower(3). Make sure the faucet is

vertical with the black handle facing the

ceiling. The faucet should then be first

“hand tightened,” then secured with the

faucet wrench(18). Now place the plastic

drip tray(5) beneath the faucet.

9

Connect Keg Coupler

To connect the keg coupler(10) to the keg(17), first make sure

the black pull handle of the keg coupler is in the closed

(diagonal/upper) position. Insert the keg coupler into the

locking neck of the beer keg and turn clockwise 25° to lock in

into place. Now the keg coupler is secured to the keg.

11

Connect Beer Line

Now connect the beer line from the

tower(3) to the keg coupler. Insert the

neoprene washer(14) (provided with

the kit) into the beer line hex nut (the

beer line is the line coming

from/going to the tower and faucet).

Remove the blue rubber protective

cap located on top of the keg coupler

and screw the nut with the neoprene

washer to the top of the keg coupler;

hand-tighten firmly.

6

Connect Tube to Regulator

Make sure the CO

2

regulator(6) shut off valve is

closed- the switch below the main body should be

perpendicular to the tubing. Install the 4 ft. CO

2

gas line tube(7) to the regulator by attaching one

end of the tube into the hose barb connection on

the CO

2

regulator. Secure the tube by using one of

the two self-locking red plastic snap-on

clamps(15). Use pliers or clamp crimpers to snap

the clamp on as high as possible. Make sure the

clamp does not impeed the valve. Then remove the

black rubber plug from the back of the unit and

feed the remaining unused end of the tubing

through the hole.

7

Connect Regulator to Cylinder

Make sure the CO

2

cylinder(8) is full and

closed. Then attach the CO

2

regulator(6)

to the CO

2

cylinder by screwing the loose

golden regulator nut into the cylinder valve

and tightening with a wrench or pliers.

Note that a fiber washer is normally

required to connect a regulator to a CO

2

cylinder, but the standard regulator

provided includes a built-in o-ring.

12

Tap Keg

To secure the tank connection,

pull the tap handle out (away

from the keg coupler(10)) and

push down until it locks into

position. Listen for the “click”

of the pull handle when it

shifts into the final downward

position. The keg is now

tapped.

10

Attach Tube to Coupler

Now attach the remaining open end of the CO

2

gas line tube(7) to

the keg coupler’s hose barb(10). Then secure the tube by using

the remaining self-locking red plastic snap-on clamp(15). Use

pliers or clamp crimpers to snap the clamp securely as close to the

coupler as possible.

13

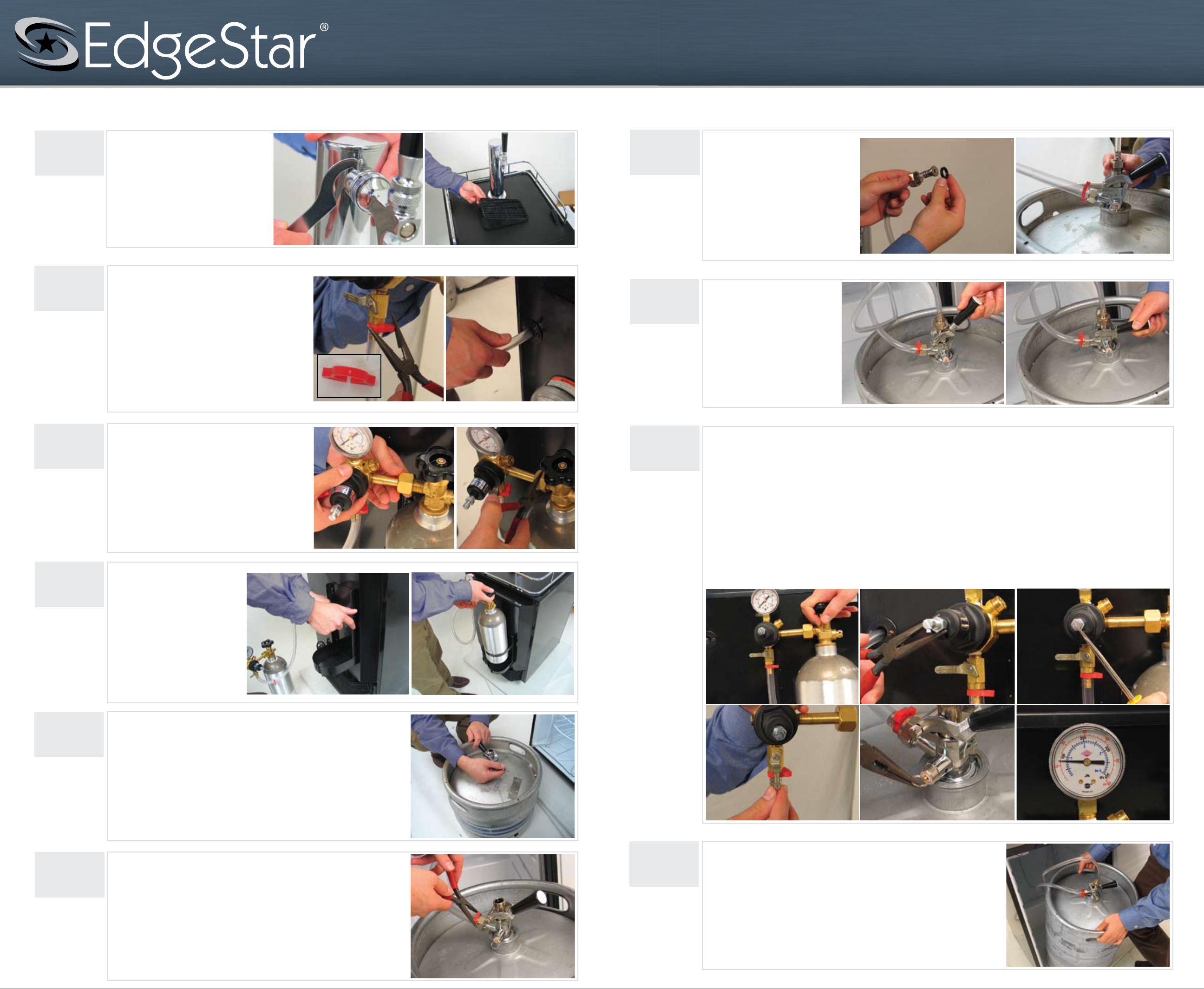

Calibrate Regulator

(A) With the shut-off valve on the regulator(6) closed, open the valve on the gas cylinder(8) completely. (B) With your

fingers or a pair of pliers, loosen adjustment nut allowing adjustment screw to be turned counter-clockwise until

adjustment screw can no longer turn. (C) Now slowly turn the regulator adjustment screw clockwise until the desired

pressure is shown on the output pressure gauge. Under normal circumstances, we recommend setting the regulator at

12psi. NOTE: Other conditions, such as altitude or special beer type, may require some adjustment. On regulators

designed for draft beer, turning clockwise will increase the output pressure, and turning counter-clockwise will decrease

the output pressure. (D) Open the shut-off valve on the regulator-the switch below the main body should be parallel to

the tubing. Gas should now flow from the regulator to the keg coupler(10). You will hear the keg pressurizing. The

output needle will drop momentarily while the pressure is equalizing. Then, the needle will return to the point you set it

at. (E) The keg coupler is designed with a pressure relief valve (PRV). Pull the ring on the PRV briefly to allow gas to

vent. This will permit gas to flow through the regulator and help obtain a more accurate reading on the output pressure

gauge. (F) Re-check the output pressure on the regulator, and if necessary re-adjust using step B until the desired

pressure is shown.

NOTE: It is always wise to follow up any adjustment to the regulator with a brief pull of the PRV ring to ensure an

accurate output reading.

Warning: CO

2

can be dangerous! CO

2

cylinders contain high-pressure gas, which can be hazardous if

handled improperly. Please handle with care.

Note: Included accessories may not be as pictured

Warning: This guide is provided for informational purposes only. If you have any questions about

the installation of this appliance, feel free to contact EdgeStar service at 866.319.5473 or consult

a qualified installer. Neither the manufacturer nor its distributors shall be liable for any incidental,

consequential, indirect, special, or punitive damages of any nature, including without limitation,

lost revenues or profits, or any other damage whether based in contract, tort, or otherwise.

BA C

D E F