Undercounter Dishwashers

Medical Line Undercounter

Internet: http://www.electrolux.com/foodservice

IBF0102009-06-19Subject to change without notice

Convertible to 230 V / 3 / 50 Hz;

230 V / 1+N / 50 Hz

230 V / 3 / 50 Hz;

230 V / 1+N / 50 Hz

230 V / 3 / 50 Hz;

230 V / 1+N / 50 Hz

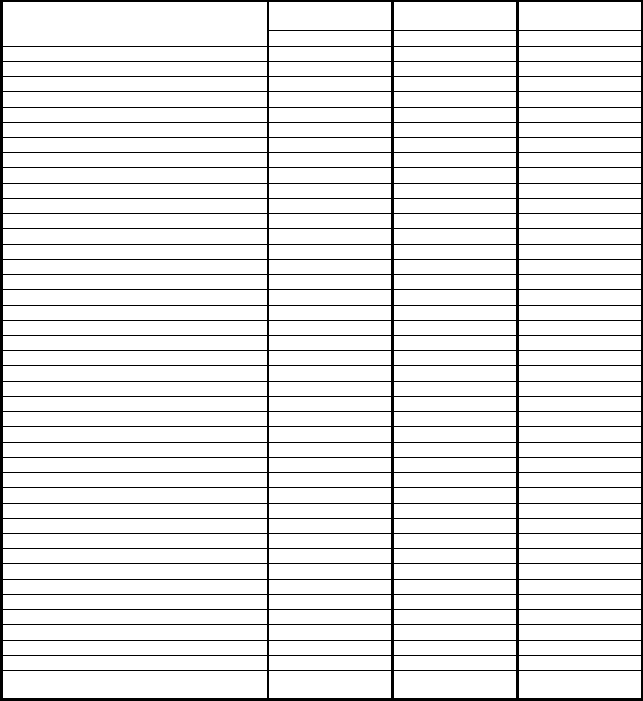

Supply voltage 400 V, 3N, 50 400 V, 3N, 50 400 V, 3N, 50

Net weight - kg. 68 71 68

Noise level - dBA <65 <65 <65

total power 6.85 6.85 6.85

Rinse pump 0.26 0.26 0.26

drain pump 0.034 0.034 0.034

Power - kW

Boiler elements - kW 6 6 6

Boiler capacity - lt. 12 12 12

water consumption - lt./cycle 7.5 7.5 7.5

temperature during rinse - °C 90 90 90

duration - sec. 30 30 30

Hot rinse cycle

electrical elements - kW 2 2 2

power pump - kW 0.736 0.736 0.736

tank capacity - lt. 23 23 23

temperature -°C 55-65 55-65 55-65

Washing cycle

height 335 335 335

depth 500 500 500

width 500 500 500

Cell dimensions - mm

height 850 850 850

depth 612 612 612

width 600 600 600

External dimensions - mm

Basket capacity/h 12 12 10

Dishes capacity/h 216 216 180

Duration cycles - sec. 300/420/600 300/420/600 360/540/660

N° of cycles 3 3 3

Rinse aid dispenser ● ● ●

Detergent dispenser ●

Rinse box ●

Rinse Booster Pump ● ● ●

Drain pump ● ● ●

Water softener ●

Thermometer ● ● ●

hardness - °f 7-14 <48 7-14

temperature - °C 50 50 65

Water supply

Open air gap (WRC) ●

TECHNICAL DATA

EUCAIML

502035

EUCAIMLWS

502036

EUCAIMLG

502037

• Front and side panels, door,

wash tank, tank filter and

wash/rinse arms made in heavy

duty anti-corrosive AISI 304

stainless steel to guarantee

appliance durability.

• 304L stainless steel atmospheric

boiler with higher welding

protection improves the resistance

against corrosion from chlorinated

water.

• PVC water supply hose with

metal connections resistant to

high water pressure.

• Completely closed on the

reverse by a cover plate while the

IPX4 water protection prevents

external infiltrations.

FLEXIBILITY AND ERGONOMICS

• The incorporated Soft Start

feature offers additional protection

to delicate items such as

glassware and crockery and

increases wash pump reliability.

• Simple control panel with digital

display allows on-site

personalization of washing and

rinsing cycle times and

temperatures as well as precise

rinse aid and detergent quantities

depending on the customers

needs.

• Three phase or single phase

electrical connection, convertible

on-site.

• All machines are pre-arranged to

accept external dispensers.

• Counterbalanced door with

springs to lighten the load when

opening and closing.

• The wash tank filters can be

removed without extracting the

washing and rinsing arms.

• Pre-arrangement for HACCP

system implementation and

Energy Management device.

EASY ON THE ENVIRONMENT

• 98% recyclable by weight.

• CFC free packaging.

• In compliance with H

requirements.

• Low noise level.

• Developed and produced in ISO

9001 and ISO 14001 certified

factory.

• Code 502037 in compliance with

WRC requirements

CONTINUOUS WATER SOFTENER

• Two resin containers

automatically alternate during

regeneration to provide non-stop

washing.

• Regeneration activated

automatically – no operator

intervention.

• 100% of rinse water regenerated

with no pressure drop during rinse

to ensure full detergent removal

and sanitization of items.

• Comfortable front loading of

regeneration salt.

* Duration cycles: declared actual cycle

duration times can extend when water

supply temperature is lower than

indicated.