11

FIRST STEPS (continued)

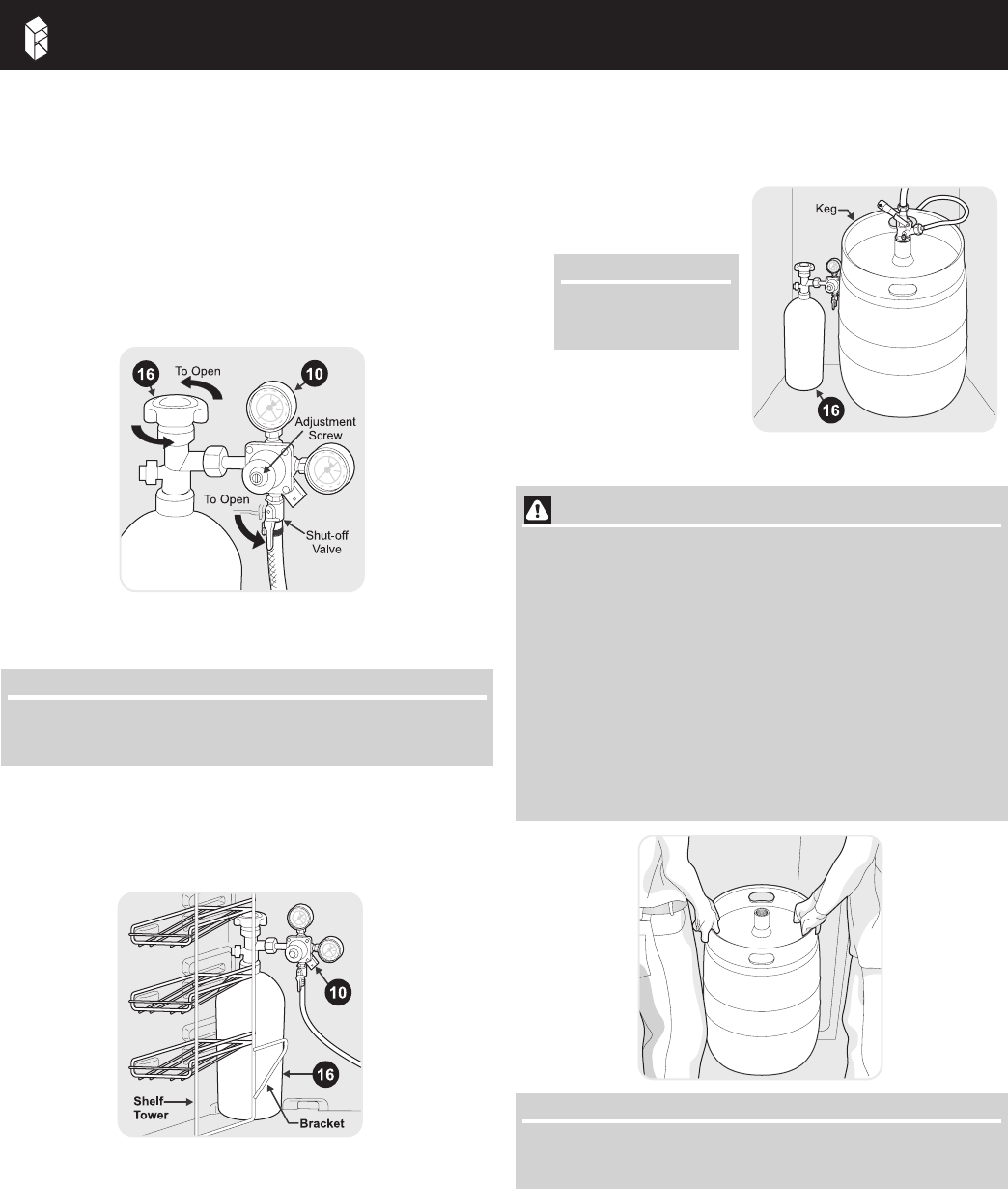

DELIVERY HOSE PRESSURIZATION

• Open the CO

2

canister valve all the way by turning

counterclockwise until it stops. This valve seals at both the

fully open and fully closed positions. Failure to completely

open or close the valve could result in premature loss of

CO

2

pressure.

• Open the regulator shut-off valve by moving it to the 6

o’clock position.

• Check gauge pressure. Adjust the Regulator Adjustment

Screw as necessary until the pressure reads between 12

to 14 psi. Tighten the Adjustment Lock Nut.

CO

2

CANISTER TO CABINET INSTALLATION

• Remove adjustable shelf from inside of cabinet.

NOTENOTE

NOTENOTE

NOTE

The adjustable shelf is intended for use with 1/4 keg or no

keg. Reinstall shelf after keg installion if using 1/4 keg.

• Lift and place the CO

2

canister (16) with the CO

2

regulator

(10) behind the shelf tower inside of the CO

2

canister bracket.

It is important that the canister be kept in an upright position

to operate efficiently.

KEG TO CABINET INSTALLATION

• Place the keg on the Support Shelf and push back next to

the CO

2

canister (16) (See TIPS ON INSTALLING KEG TO

THE CABINET) inside the cabinet as shown.

TIPS ON INSTALLING THE KEG TO THE CABINET

WARNING WARNING

WARNING WARNING

WARNING

SAFE KEG HANDLING

• Installing the keg to the cabinet is a two-person team

effort. NEVER lift a full ½ keg alone. Doing so may cause

severe injury.

• With the door fully open and the help of another person,

lift the keg vertically on both sides until the keg is higher

than the keg support shelf.

• Set the edge of the keg on top of the plastic protective

plate located on top of keg support shelf. Slide the keg

back until it is fully inside the cabinet.

• Care must be taken to avoid damage to the temperature

control and shelf tower located in the cabinet.

NOTENOTE

NOTENOTE

NOTE

The above illustration does not show the tap installed for

clarity of installation.

NOTENOTE

NOTENOTE

NOTE

Shelf tower has been

removed for clarity.