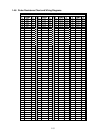

1-9

10. Invert the cookpot or rinse tank on a suitable work surface and remove the salvageable

components (e.g., probe block assembly, blower assembly, drain plumbing, etc.). Install the

recovered components on the replacement cookpot or rinse tank, using thread sealer on all

connections.

11. Reverse Steps 1 through 9 to complete the procedure.

1.4 Troubleshooting

Problems with this equipment maybe grouped into five broad categories:

1. Failure or malfunction of a Power-Supply System component.

2. Failure or malfunction of the Controller.

3. Failure or malfunction of an Autofill/Autoskim System component.

4. Failure or malfunction of a Water Heating System component.

5. Failure or malfunction of a Basket Lift System component.

Sections 1.4.1 through 1.4.5 briefly explain the functioning of each of the systems mentioned above.

Section 1.4.6 contains troubleshooting guides that provide systematic procedures to isolate and

identify the specific source of a problem. A wiring diagram is located at the end of the chapter.

1.4.1 How the Power-Supply System Works

Line voltage is supplied to the system via a power cord that is plugged or hard-wired into the store’s

electrical service. The power cord is connected to pins 1 and 5 of an 8-pin terminal block. Line

voltage is supplied to a 24VAC transformer from pins 2 and 8 of the terminal block. Pin 7 supplies

24VAC to a heat relay, which controls line voltage to the blower motor and 24VAC to the gas valve

via the ignition module. The transformer supplies 24VAC to the controller, to the coils of the

24VAC relay, and to the solenoid valve on units equipped with the Autofill option. On units

equipped with basket lifts, line voltage is supplied to a 24VDC basket lift relay from pin 6 of the

power cord terminal block. Line voltage to the basket lift motors is supplied via the basket lift relay.

1.4.2 How the Controller Works

The SMS III controller provides the interface between the operator and the system components. The

controller is powered by 24VAC supplied through Pins 1 and 2 of the wiring harness. Internal cir-

cuitry senses the water level and water temperature. Depending upon the conditions sensed, the con-

troller energizes or de-energizes the solenoid valve to control water level and the 24VAC relay to

control burner firing to control water temperature. The controller also controls the lowering and

raising of the basket lift, and activates an audible alarm to signal the operator that a cooking cycle

has completed. A rectifier in the controller converts 24VAC to the 24VDC required by the basket

lift relay. The controller signals for heat via Pin 4, grounds the solenoid valve via Pin 6, and senses

water level via Pins 7 (low) and 9 (full). The temperature probe connects to Pins 13 and 14. The

basket lift relay connects to Pins 10 and 12. The sound device connects to Pin 11.