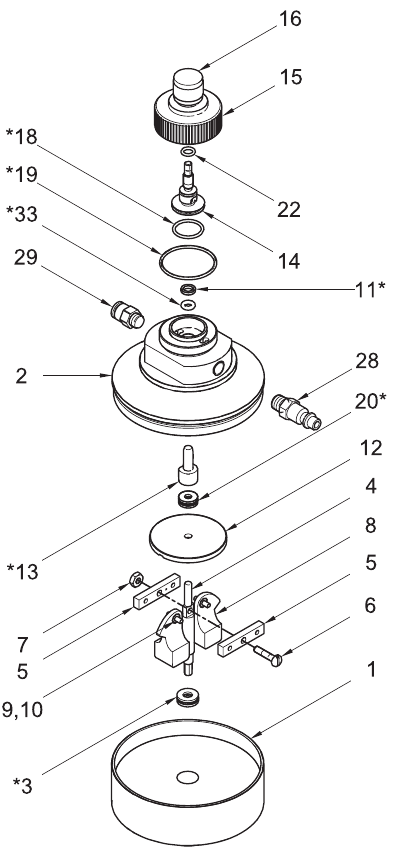

Repair

NOTE: To repair the agitator, see your separate

agitator manual.

NOTE: Repair Kit 24J886 is available. Order the kit

separately. Kit parts are marked with an asterisk, for

example (3*). For the best results use all the parts

in the kit.

NOTE: Use multi-purpose lithium based grease

where ever lubrication is required. Order Part No.

111920.

1. Disconnect the main air line to the speed

controller.

2. Disconnect the tube (27) connecting the speed

controller and air motor.

3. Unscrew the adjustment nut (15) from the upper

housing (2). Turn the knob (16) fully clockwise

(inward) to access the o-ring (18) on the bottom

plate of the seat (14). Remove the o-ring and

replace with the new o-ring (18*). Lubricate the

o-ring.

4. Remove the large o-ring (19) on the upper

housing (2). Replace with a new o-ring (19*).

Lubricate the o-ring.

5. Unscrew the upper housing (2) from the lower

housing (1). The drive shaft (4) and cam arms (8)

may come out of the lower assembly.

6. Remove the two ball bearing assemblies (3, 20)

from the drive shaft (4). Replace with the new

ball bearing assemblies. Install the larger ball

bearing assembly (3) on the bottom of the shaft.

Install the smaller ball bearing assembly (20*) on

the top of the shaft, above the large washer (12).

NOTE: The ball bearing assemblies each consist

of one bearing and two washers. Place one

washer above the bearing and the other washer

below the bearing before installing the assembly.

7. Push the needle (13) out of the upper housing

(2) from the top. Using an o-ring pick, remove

the u-cup (11) and o-ring (33) from the upper

housing. Lubricate the new o-ring (33*) and

u-cup (11*) and install in the upper housing. The

lips of the u-cup must face up.

8. Lubricate the new needle (13*) and install in the

upper housing (2) from the bottom, being sure to

align the flat face on the needle with the mating

flat surface in the housing.

9. Ensure that the cam arms (8) align with the

groove on the bottom side of the large washer

(12). Install the drive shaft (4) and cam arm

assembly into the lower housing (1), making sure

the bearing (3*) seats fully in the recess of the

housing.

10. Screw the upper housing (2) fully onto the lower

housing (1).

11. Turn the adjustment knob (16) all the way

counterclockwise (outward). Screw the

adjustment nut (15) fully onto the upper housing

(2).

12. Connect the air tubing (27) between the speed

controller tube connector (29) and the air motor

tube connector (21).

13. Return the unit to service. Connect the main air

line to the quick-disconnect fitting (28) on the

speed controller.

ti17005a

3A1315A

7