IN THIS GROOVE.

RETAINER PLATE

DO NOT PLACE

IN THIS GROOVE.

DO NOT PLACE

RETAINER PLATE

DAMPER FRAME

DAMPER FRAME

WOOD

STUD

MIN

1.00

STUD

METAL

1.00

MIN

3

Installation - Continued

2. SLEEVE LENGTH AND WALL/FLOOR

THICKNESS

Insert the damper assembly into the prepared opening,

to appropriate depth (see page 2, Fig. 1).

Recommended maximum and minimum insertion depth

can be exceeded as long as the

C

L

of the damper

blade remains within the plane of the wall/floor.

IMPORTANT SAFETY DANGER! To avoid causing

death or serious bodily harm to building occupants, do

not insert screws into the damper frame unless used

for duct connection within 2 in. (51mm) of the frame

end.

The sleeve may extend a maximum of 6 in. (152mm)

beyond both sides of the wall or floor. Recommended

standard sleeve lengths for various wall/floor

thicknesses are:

3. DUCT TO SLEEVE CONNECTIONS

Dampers are supplied with sleeves from the factory

and can be installed without the need for additional

field installed sleeves.

Gauge of factory furnished sleeve determines the

type of duct to sleeve connections required (see table

below). Any duct connection other than the breakaway

connections are considered rigid.

Opening + 2 in. Min.

Wall/Floor Opening

= Nominal Size + 7/8 in. Min.

1.00 in. T y p.

Fasteners

Clamping

Screw

Nut

Retaining

Plate Assembly

Clamping Screw

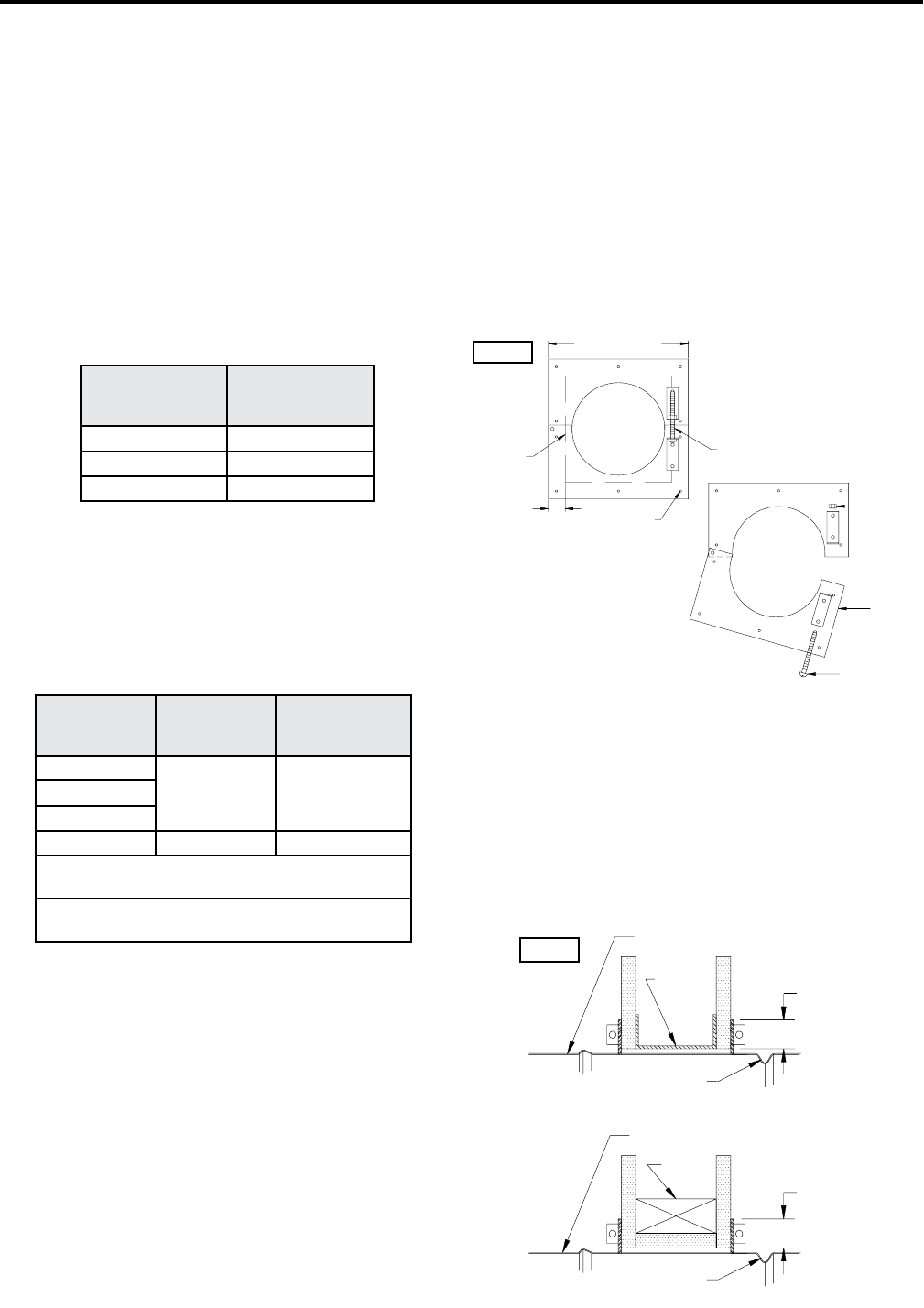

Fig. 2

5. Recommended Preparation of Openings in

Wood and Metal Stud Walls

• Frame wall openings as shown below. (see Fig. 3)

• Double vertical studs are not required for openings

36 in. x 36 in. (914mm x 914mm) or smaller.

• Gypsum wall board must be fastened 12 in. (305mm)

on center to all stud and runner flanges surrounding

opening. (see Fig. 4)

• All construction and fasteners must meet the

requirements of the appropriate wall design (See UL

Fire Resistance Directory) and/or local codes.

Fig. 3

4. SECURING THE DAMPER/SLEEVE ASSEMBLY

TO WALL AND FLOOR OPENINGS

Damper assemblies must be installed in wall/floor

openings using a single retaining plate on either side

of the wall/floor or by using a retaining plate on both

sides of the wall/floor. The use of a second retaining

plate is allowed, but is not necessary. A single retaining

plate is provided with the dampers. A second retaining

plate can be ordered as an option.

• The retaining plate(s) will open up for easy installation

when the clamping screw is loosened. If necessary,

remove the clamping screw and nut (see Fig. 2).

(IMPORTANT: The clamping mechanism should

face away from the wall/floor). Retainer plate(s) are

designed to mount flush to the wall/floor and hold the

damper in the wall/floor opening.

Opening + 2 in. Min.

Wall/Floor Opening

= Nominal Size + 7/8 in. Min.

1.00 in. T y p.

Fasteners

Clamping

Screw

Nut

Retaining

Plate Assembly

Clamping Screw

Wall/Floor Thickness

Dimension (T

w

)

Inches (mm)

Sleeve Length

Dimension (L)

Inches (mm)

Up to 6½ (165) 13 5/8 (346)

6½ - 8½ (165 - 216) 15 5/8 (397)

8½ - 10½ (216 - 267) 17 5/8 (448)

Sleeve Gauge

(mm)

Duct Dimension

Maximum

Inches (mm)

Type of Duct to

Sleeve Connection

Permitted

10 ga. (3.5)

24 (610) Rigid or Breakaway14 ga. (2)

16 ga. (1.5)

20 ga. (1mm) 24 (610) Breakaway only

Sleeve thickness must not be less than the gauge of the

connecting duct.

UL Standard 555 requires all ducts to terminate at fire damper

sleeves.

• Place the damper and attached retainer plate into the

wall/floor opening.

• If a second retaining plate is being used, secure it on

the opposite side of the wall/floor

DO NOT POSITION RETAINER PLATE(S) IN

FRAME GROOVE

• Verify position, blade orientation, and actuator

clearance then tighten the retainer plate clamping

screws. The retainer plate(s) must overlap the wall/

floor opening a minimum of 1 inch (25mm). Secure

the retainer plate(s) to the wall using appropriate

fasteners (minimum #8 sheet metal screws) at the

four corners of each retainer plate when two retainer

plates are used and also within ¾ in. (19mm) of the

center of each plate when one retainer plate is used.