5

Model SQ/BSQ • Centrifugal Inline Exhaust Fans

®

Duct Length: The inlet and outlet duct length

should be approximately two to three wheel

diameters long before and after the fan to achieve

cataloged performance.

Side Discharge: Make sure discharge is

orientated in the same direction as originally

ordered, performance will change with different

discharge positions. Refer to Figure 12 for

proper side discharge definition and chart 4 for

dimensions, page 4. Refer to the CAPS program or

consult factory for performance corrections.

Pre Start-Up Checks

1. Check all fasteners for tightness. The wheel

should rotate freely and be aligned as shown

in Figure 13. Wheel position is preset and the

unit is tested at the factory. Movement may

occur during shipment, and realignment may

be necessary. Centering can be accomplished

by loosening the bolts holding the inlet (venturi)

panel and repositioning. Wheel and inlet cone

overlap can be adjusted by loosening the

setscrews in the wheel and moving the wheel to

the desired position.

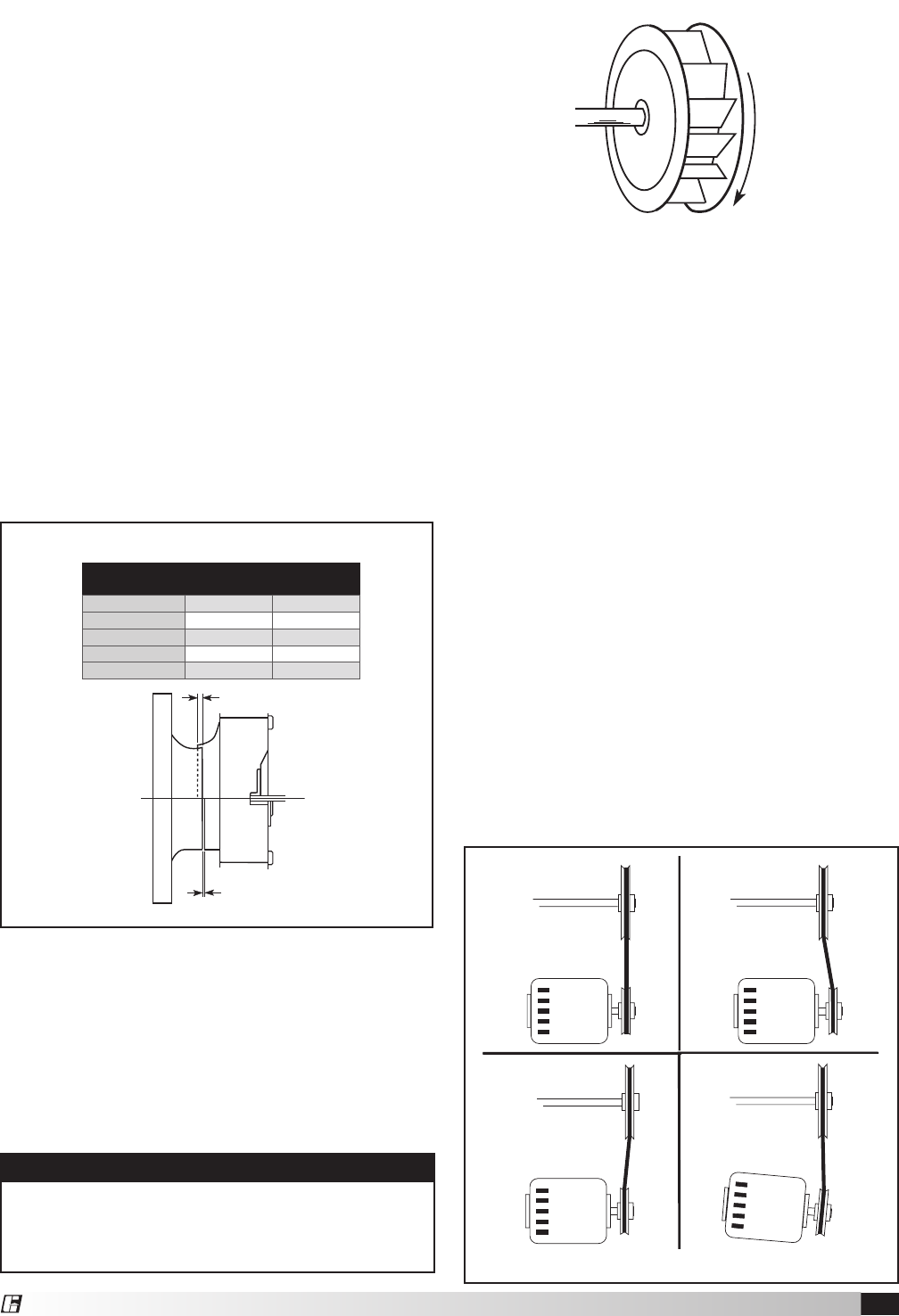

2. Wheel Rotation: Direction of wheel rotation

is critical. Reversed rotation will result in poor air

performance, motor overloading and possible

burnout. Check wheel rotation by momentarily

energizing the unit (all SQ and BSQ fans have

clockwise wheel rotation when viewed from top

of fan). Rotation should be clockwise as shown

in Figure 14 and correspond to the rotation

decal on the unit.

3. Vibration Isolators: After fan is moved to

desired location, punch out the four knock-out

holes which are located on the unit top and

bottom panels. Assemble the brackets to the

unit according to the appropriate drawings

on page 4 and refer to respective parts list on

page 11. Make certain all connectors are tight

and that all washers are in.

4. For BSQ Fans: If adjustments are made, it is

very important to check the pulleys for proper

alignment. Misaligned pulleys lead to excessive

belt wear, vibration, noise, and power loss. (see

Figure 15).

5. For BSQ Fans: Belt tension can be adjusted

by loosening four fasteners marked “R” on

the drive frame. (refer to Figure 17 on page 6).

The motor plate slides on the slotted adjusting

arms. Belt tension should be adjusted to allow

1/64 inch of deflection per inch of belt span.

For example, a 15 inch belt span should have

15/64 inch (or about 1/4 inch) of deflection with

moderate thumb pressure at mid-point between

pulleys (see Figure 16). Overtightening will

cause excessive bearing wear and noise. Too

little tension will cause slippage at start-up and

uneven wear.

Wheel Overlap Dimensions

Figure 13

Model

G - Overlap

in. (mm)

H - Gap

in. (mm)

SQ 60-95

-

1/8 (3)

SQ 100-160 1/4 (6)

-

BSQ 70-160 1/4 (6) -

BSQ 180-240 3/8 (10)

-

BSQ 300-420 1/2 (13)

-

G

H

C

l

o

c

k

w

i

s

e

Figure 14

Figure 15

Belt Span

Deflection =

Belt Span

64

WRONGWRONGWRONGCORRECT

G

C

l

o

c

k

w

i

s

e

Belt Span

Deflection =

Belt Span

64

WRONGWRONGWRONGCORRECT

G

C

l

o

c

k

w

i

s

e

Belt Span

Deflection =

Belt Span

64

WRONGWRONGWRONGCORRECT

G

C

l

o

c

k

w

i

s

e

WARNING

Correct direction of wheel rotation is critical.

Reversed rotation will result in poor air

performance, motor overloading and possible

burnout.