6

Model SQ/BSQ • Centrifugal Inline Exhaust Fans

®

WARNING

The fan has been checked for mechanical noises

at the factory prior to shipment. If mechanical

noise should develop, suggested corrective ac-

tions are offered in the Troubleshooting section.

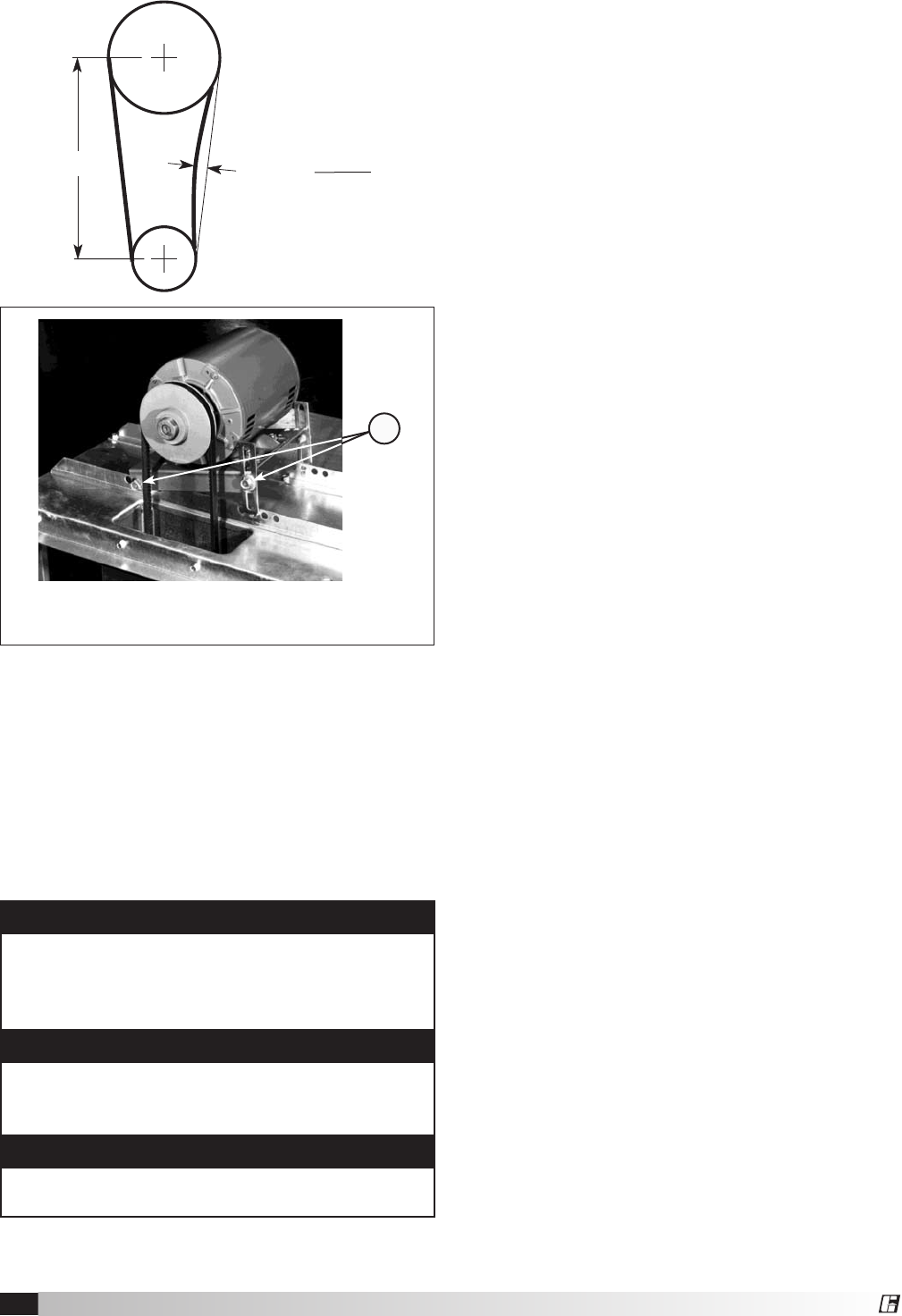

IMPORTANT

Over tightening will cause excessive bearing wear

and noise. Too little tension will cause slippage at

start-up and uneven wear.

IMPORTANT

Adjust (tighten) belt tension after the rst 24-48

hours of operation.

6. The adjustable motor pulley is factory set for

the RPM specified. Speed can be increased by

closing or decreased by opening the adjustable

motor sheave. Two groove variable pitch pulleys

must be adjusted an equal number of turns open

or closed. Any increase in speed represents a

substantial increase in the horsepower required

by a unit. Motor amperage should always be

checked to avoid serious damage to the motor

when speed is varied.

Belt Span

Deflection =

Belt Span

64

WRONGWRONGWRONGCORRECT

G

C

l

o

c

k

w

i

s

e

Figure 16

Figure 17

NOTE: Identical fasteners on opposing side must

also be loosened.

R

Operation: SQ / BSQ

1. Before starting up or operating fan, check all

fasteners for tightness. In particular, check

the setscrews in wheel hub (and pulleys, if

applicable).

2. While in the OFF position or before connecting

the fan to power, turn the fan wheel by hand

to be sure it is not striking the venturi or any

obstacle.

3. Start the fan and shut it off immediately to check

rotation of the wheel with directional arrow in the

motor compartment, see Figure 14.

4. When the fan is started, observe the operation

and check for any unusual noises.

5. With the system in full operation and all

ductwork attached, measure current input to the

motor and compare with the nameplate rating to

determine if the motor is operating under safe

load conditions.

6. Keep inlets and approaches to fan clean and

free from obstruction.

Inspection: SQ / BSQ

Inspection of the fan should be conducted at the

rst 30 minute and 24 hour intervals of satisfactory

operation.

30 Minute Interval

Inspect bolts, setscrews and motor mounting bolts.

Adjust and tighten as necessary.

24 Hour Interval

Check all internal components. On BSQ unit only,

inspect belt alignment and tension. Adjust and

tighten as necessary.