Maintenance

Once the fan has been put into operation, a periodic

maintenance program should be set up to preserve

the reliability and performance of the fan. Items to be

included in this program are:

t #FMUT t 3FNPWBMPGEVTUBOEEJSU

t 'BTUFOFST t 'BOTIBGUCFBSJOHT

t 4FU4DSFXT t 7FLUPS)4OP[[MFCFBSJOHT

t .PUPST t 3FMVCJDBUJPOTDIFEVMF

Belts

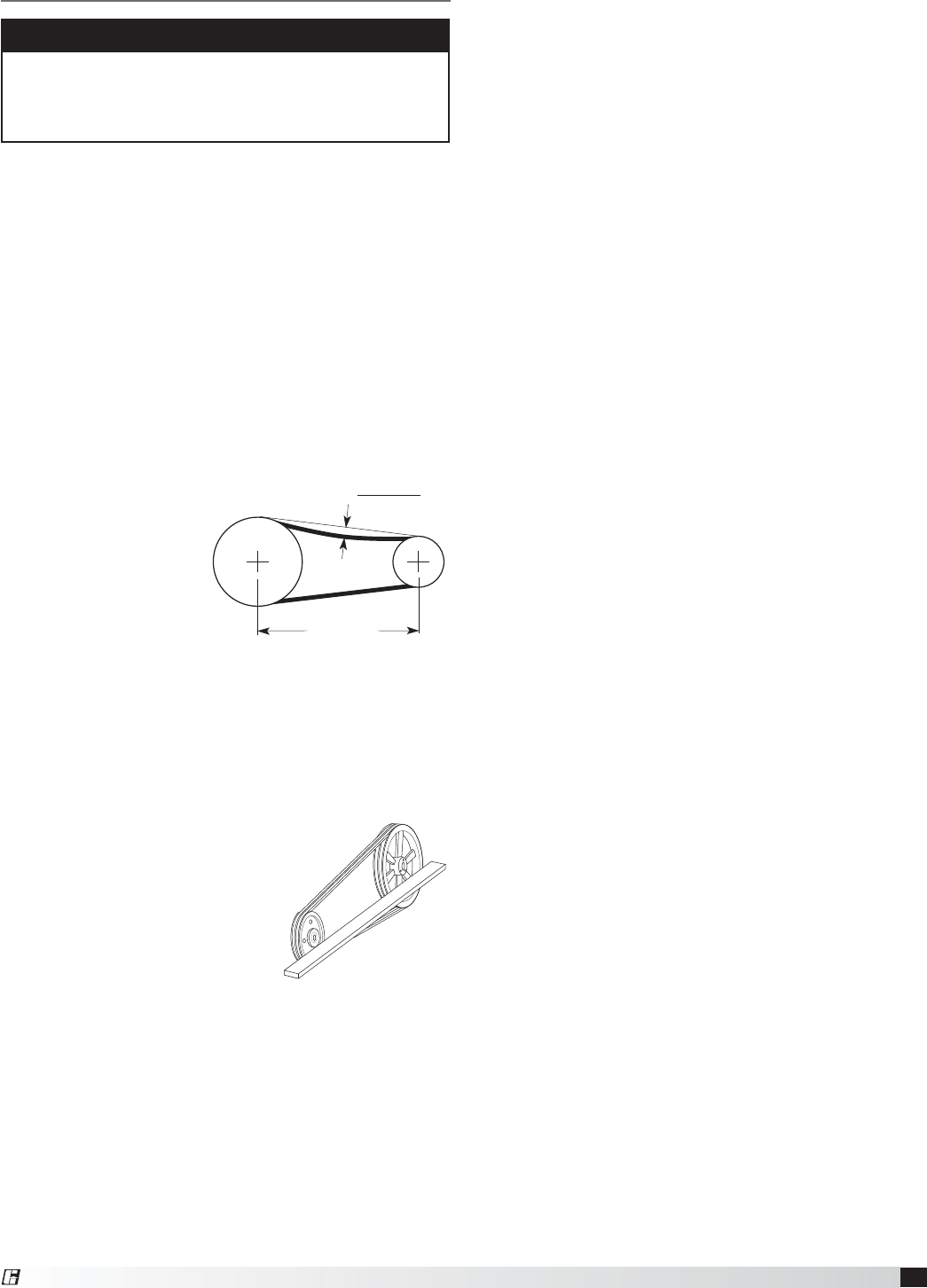

Premature belt failures are frequently caused by

improper belt tension (either too tight or too loose) or

misaligned pulleys. The proper tension for operating a

V-belt is the lowest tension at which the belts will not

slip at peak load conditions. For initial tensioning, the

proper belt deflection

half-way between pulley

centers is 1/64 inch for

each inch of belt span.

For example, if the belt

span is 64 inches, the

belt deflection should be

one inch using moderate

thumb pressure at

midpoint of the drive.

Check belt tension two times during the first 24 hours

of operation and periodically thereafter. To adjust belt

tension, simply loosen four fasteners (two on each side

of the motor plate) and slide the motor plate away from

the fan shaft until proper belt tension is attained. On

some fans, fasteners attaching the motor to the motor

plate must be loosened in order to adjust

the belt.

It is very important that the drive

pulleys remain in proper alignment

after adjustments are made.

Misalignment of pulleys will result

in premature belt wear, noise,

vibration and power loss.

Fasteners and Set Screws

A periodic inspection should include checking all

fasteners and set screws for tightness. Particular

attention should be paid to set screws attaching the

wheel to the shaft.

WARNING

Disconnect all electrical power to the fan and secure

to the ‘OFF’ position prior to inspection or servicing.

Failure to comply with this safety precaution could

result in serious injury or death.

Motors

Many fractional horsepower motors installed on the

smaller fans are lubricated for life and require no further

attention. Motors supplied with grease fittings should be

greased according to directions printed on the motor.

Removal of Dust and Dirt

Dirt clogs cooling openings on the motor housing,

contaminates bearing lubricant, and collects on the

impeller causing severe imbalance if left unchecked.

The exterior surface of the motor and impeller should be

thoroughly cleaned periodically. Use caution and do not

allow water or solvents to enter the motor or bearings.

Under no circumstances should motors or bearings be

sprayed with steam or water.

Fan Shaft Bearings

The bearings for Greenheck fans are carefully selected

to match the maximum load and operating conditions

of the specific class, arrangement, and fan size. The

instructions provided in this manual and those provided

by the bearing manufacturer will minimize any bearing

problems. Bearings are the most critical moving part

of the fan; therefore, special care is required when

mounting them on the unit and maintaining them.

Locking collars and set screws, in addition to fasteners

attaching the bearing to the bearing plate must be

checked for tightness. Greenheck Fan Corporation

recommends bearings to be relubricated quarterly at a

minimum. All Vektor-H and Vektor-HS fans use Mobil

Mobilith SHC 100 synthetic grease conforming to

NCGI Grade 2. Never mix greases made with different

bases as this will cause a breakdown of the grease and

possible failure of the bearing. For specific information,

contact the factory representative or the fan system

submittals.

t 'PSDPOEJUJPOTJODMVEJOHUFNQFSBUVSFTNPJTUVSF

dirt or excessive vibration, consult the factory for a

specific lubrication interval for your application.

t -VCSJDBOUTIPVMECFBIJHIRVBMJUZMJUIJVNDPNQMFY

synthetic grease conforming to NLGI Grade 2.

t 5IFVTFPGOPOTZOUIFUJDHSFBTFXJMMEFDSFBTF

lubrication intervals by approximately 3 times.

t 4UPSBHFQFSJPETPGNPOUITPSMPOHFSSFRVJSF

monthly rotation of the shaft and purging grease

prior to storage and start-up.

Belt

Alignment

Deflection =

Belt Span

64

Belt Span

Belt Tension

9

Laboratory Exhaust System

®