Crathco

®

Remote Beverage Freezers Page 9

Disassembly and Cleaning (cont.)

5. Slide the rotary half of the seal off the dasher shaft. Inspect both seal components

carefully for nicks or cracks. Replace seal if defective.

NOTE: To prevent leakage, the surfaces of the rotary seal and stationary seal must be

smooth with no chips or cracks.

NOTE: All units are shipped with a standard ceramic seal (#W0340201) unless otherwise

specified. Certain products contain a coconut oil with requires a different sealing material.

For these products use the coconut oil seal (#W0340210). The stationary half of the

standard seal has a white polished surface. The stationary half of the coconut oil seal

has a glossy black surface.

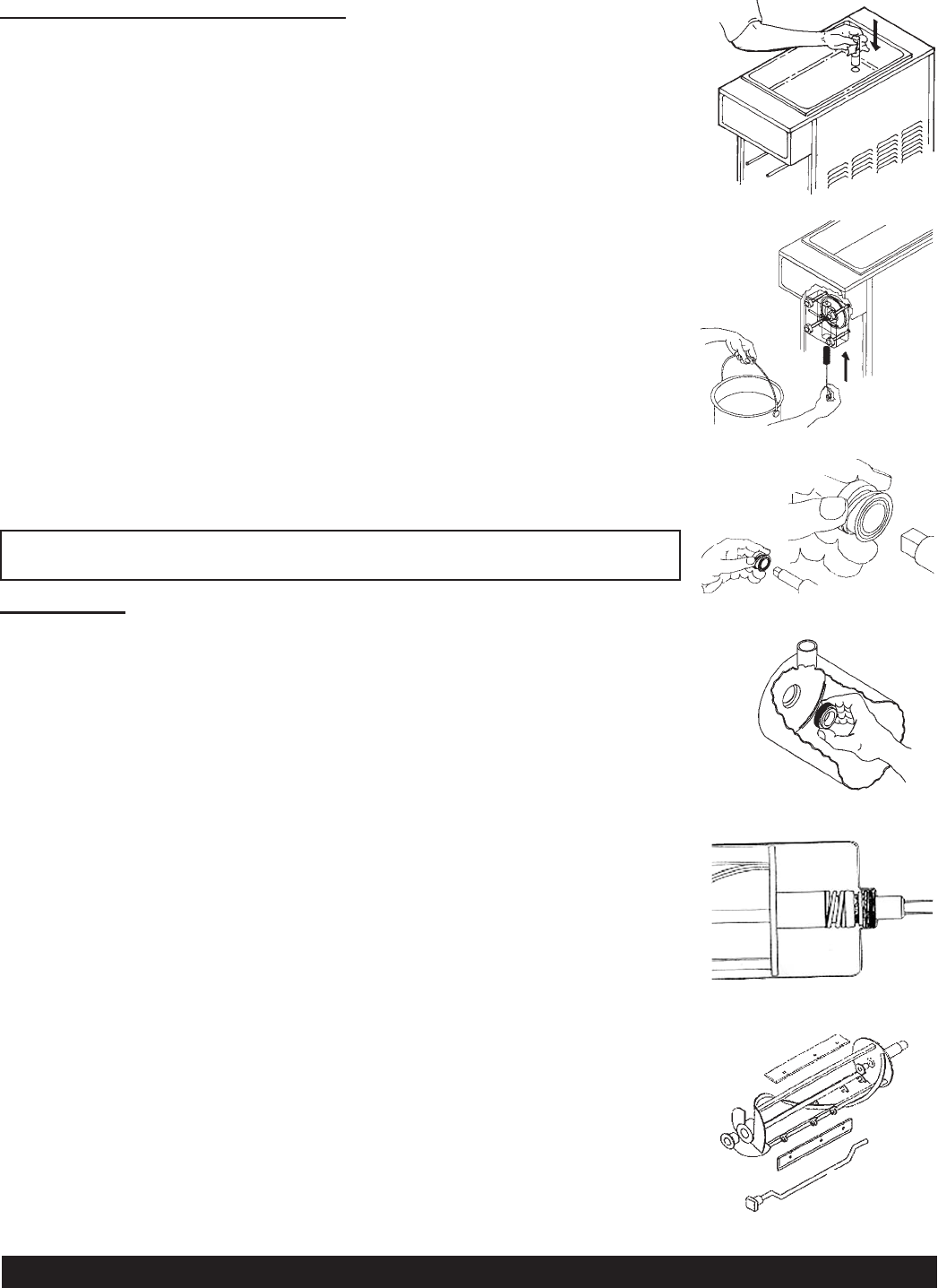

6. Remove carb tube from bottom of hopper and remove o-rings. (see Figure P).

7. Remove drip tray and empty contents.

8. Take all components to the cleaning area.

9. Prepare 1 gallon solution of hot tap water and a good grade of dishwashing detergent.

10. Thoroughly wash all components in a warm, mild detergent solution, including

the inside of the freezing cylinder and mix storage hopper. DO NOT WASH

COMPONENTS IN A DISHWASHER.

11. Use a medium sized brush to clean the bottom of the valve body and the inside

of the plunger bore with detergent solution taking care to remove all remaining

lubricant (figure Q).

12. The exterior of the freezer should be cleaned as needed with a cloth towel.

CAUTION: Coarse rages, abrasive cleaners and excessive force can damage

and/or scratch the surfaces of the freezer.

Reassembly

NOTE: Allow all parts to dry completely before reassembly.

1. Reassemble drip tray and install.

2. Wet the inner rubber lip of the rotary half of the seal and the back end of the dasher

shaft with water. Slide rotary half of assembly onto the dasher shaft, RUBBER

FIRST, with the smooth sealing surface toward the back of the dasher. (see Figure R).

Be sure the rotary half is fully seated against the shoulder of the shaft.

3. Insert the stationary half of the seal into the ribbed rubber boot with the polished

surface facing out (forward).

4. Lightly lubricate the ribbed rubber boot of the stationary ceramic seal, (taking care

not to get any lubricant on the polished surface) and insert it straight back into the

recess at the back of the freezing cylinder, RUBBER FIRST. (Figure S)

NOTE: The stationary half of the seal must be completely dry before reassembling.

If the circular half of the seal is white, make sure that the grooved side is toward

the rubber. If the circular half is black, be sure the glossy side is facing out.

5. Reassemble the dasher assembly, as shown in Figure T. Insert the larger front

and smaller rear white plastic bearings into dasher, then slip in the stator rod.

6. Carefully and slowly guide the dasher into the freezing cylinder, taking care

not to damage the seal assembly. Turn dasher shaft until it engages the square

drive coupling. Slide the dasher back into the cylinder so that the two smooth

sealing surfaces meet. (see Figure U)

7. Inspect and lightly lubricate the large square o-ring and refit it into the back of the

valve block assembly. Install the valve assembly on the front studs and tighten the

knobs until they are finger tight. Use a cross tightening pattern. Do not use tools

to tighten knobs.

NOTE: Failure to lightly lubricate the large o-ring before installing into the valve block

can result in product leakage.

Figure Q Clean Valve Body

Figure P Carb Tube

Figure R Re-assemble rotary

portion of seal as shown

Figure S Installing the

stationary portion seal

Figure T Seal Assembly

installed correctly

Figure U Dasher Assembly

ƽ